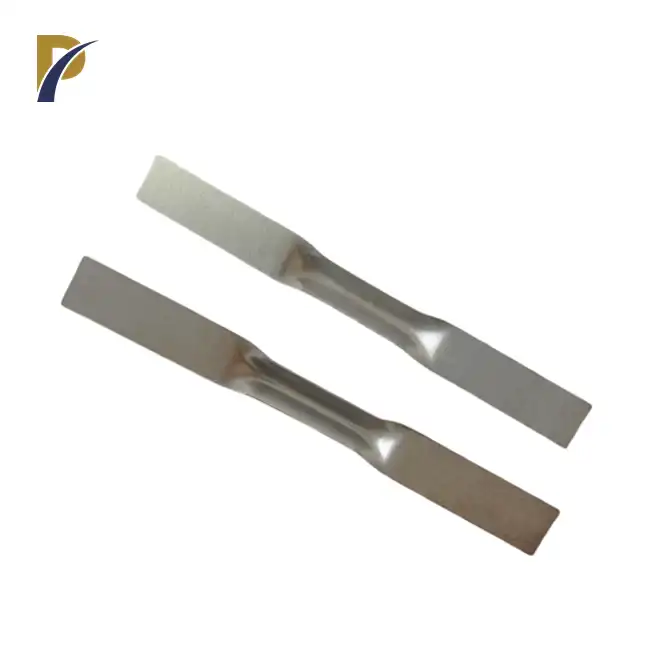

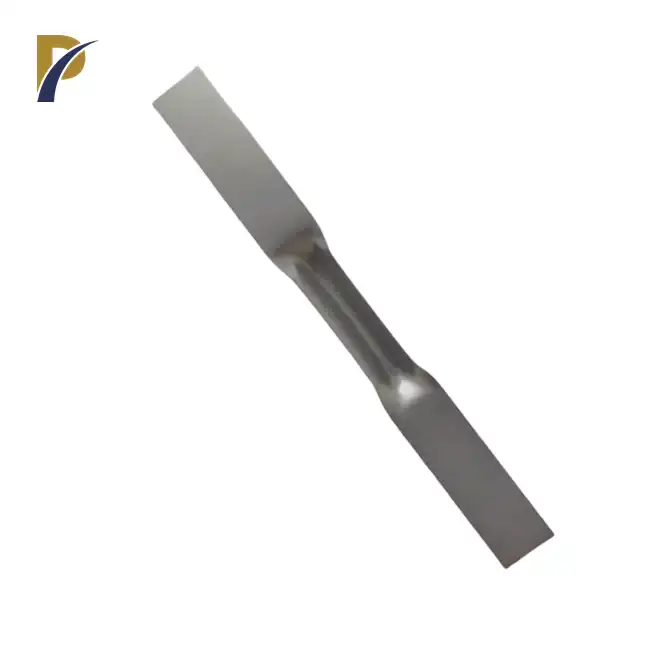

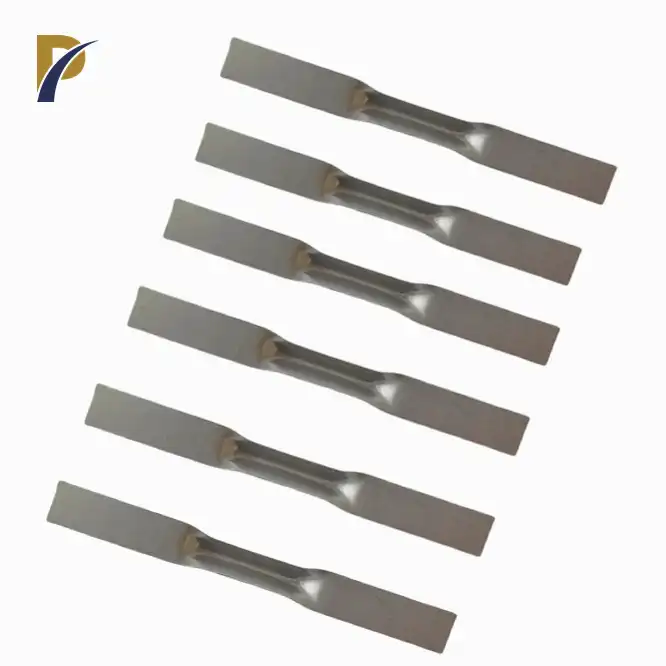

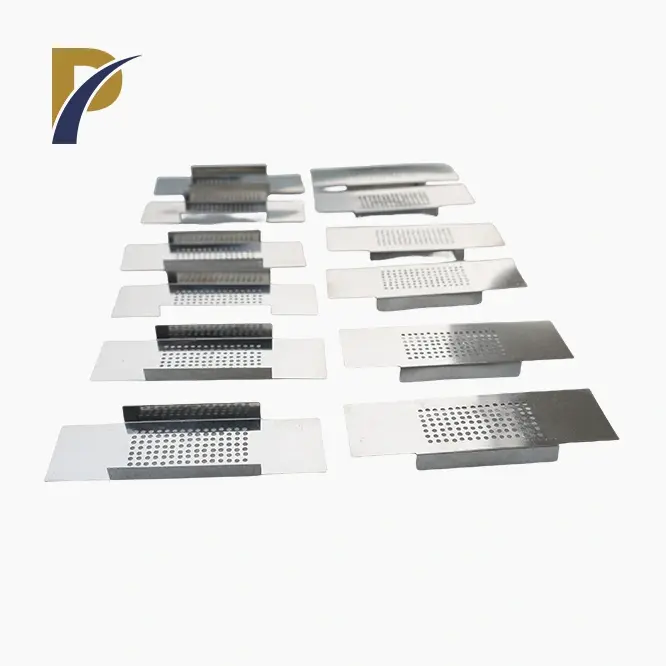

molybdenum evaporation boat

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Product Introduction:

Molybdenum evaporation boats are essential components in the thin-film deposition industry, commonly used for vacuum evaporation processes where high melting point metals are required. These boats are utilized for the thermal evaporation of materials in the coating of optical, electronic, and photovoltaic products. As a critical part of vacuum metallization, molybdenum evaporation boats offer high temperature resistance, minimal contamination, and excellent thermal conductivity, making them the preferred choice in industries that require precise and efficient evaporation processes.

Shaanxi Peakrise Metal Co., Ltd., a leading supplier of molybdenum evaporation boats, has established a strong reputation for producing high-quality non-ferrous metal products. With extensive experience in the production of tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel products, we are committed to providing global customers with high-performance molybdenum evaporation boats that meet the most demanding industrial requirements. Our products are recognized for their durability, stability, and precision in operation.

Product Parameters:

| Specification | Value |

|---|---|

| Material Composition | Pure Molybdenum (99.95%) |

| Operating Temperature | Up to 1800°C |

| Density | 10.2 g/cm³ |

| Electrical Conductivity | 1.87 × 10⁶ S/m |

| Thermal Conductivity | 138 W/m·K |

| Tensile Strength | 450 MPa |

| Surface Roughness | ≤ Ra 0.8 µm |

| Specification | Value |

|---|---|

| Melting Point | 2620°C |

| Vapor Pressure | Low |

| Evaporation Rate | Adjustable |

| Dimension Range | 50mm to 300mm length |

| Width | 10mm to 30mm |

| Thickness | 0.2mm to 0.5mm |

| Customization | Available |

| Specification | Value |

|---|---|

| Corrosion Resistance | Excellent |

| Oxidation Resistance | High |

| Application Field | Thin-film deposition |

| Hardness | 5.5 (Mohs scale) |

| Manufacturing Tolerance | ±0.01 mm |

| Usage | Reusable |

|

|

|

Physical and Chemical Properties:

- High Melting Point: Molybdenum boats can withstand extreme temperatures, up to 2620°C, making them ideal for high-temperature evaporation processes.

- Thermal Conductivity: With a thermal conductivity of 138 W/m·K, molybdenum boats ensure even heat distribution, resulting in uniform evaporation rates.

- Corrosion Resistance: Molybdenum exhibits excellent resistance to corrosion, ensuring the longevity of the boats even in harsh environments.

- Low Vapor Pressure: The low vapor pressure of molybdenum reduces the risk of contamination during the evaporation process, ensuring high purity in the final product.

|

Type |

Thickness( mm) |

Width( mm) |

Length( mm) |

Manufacturer |

|

#207 |

0.2 |

7 |

100 |

Shaanxi Peakrise Metal CO.,Ltd |

|

#215 |

0.2 |

15 |

100 |

|

|

#308 |

0.3 |

8 |

100 |

|

|

#310 |

0.3 |

10 |

100 |

|

|

#315 |

0.3 |

15 |

100 |

|

|

#413 |

0.4 |

13 |

50 |

|

|

#525 |

0.5 |

25 |

78 |

Product Functions:

- Efficient Material Evaporation: Molybdenum evaporation boats enable the efficient evaporation of materials for thin-film deposition processes, used in the production of semiconductors, photovoltaic cells, and optical coatings.

- Heat Resistance: These boats can operate at high temperatures without deformation, ensuring stable performance during extended use.

- Contamination-Free Process: Due to their high purity and low vapor pressure, molybdenum boats minimize the risk of contamination, making them suitable for applications requiring high material purity.

- Durable and Reusable: With strong mechanical properties and corrosion resistance, molybdenum evaporation boats are durable and can be reused multiple times in various industrial settings.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications:

- Semiconductor Industry: Molybdenum evaporation boats are used in the deposition of metal films in semiconductor devices, ensuring precise material control during fabrication.

- Optical Coating: The boats play a crucial role in depositing thin metal films on optical lenses and mirrors, improving reflectivity and light transmission.

- Photovoltaic Cells: Molybdenum boats are used for coating solar cells with conductive materials, enhancing energy efficiency and durability.

- LED Manufacturing: In LED production, molybdenum boats contribute to the deposition of conductive films that optimize light emission efficiency.

- Aerospace and Defense: Used for producing thin films on sensitive equipment, molybdenum evaporation boats provide the reliability and precision needed in high-tech aerospace and defense applications.

|

|

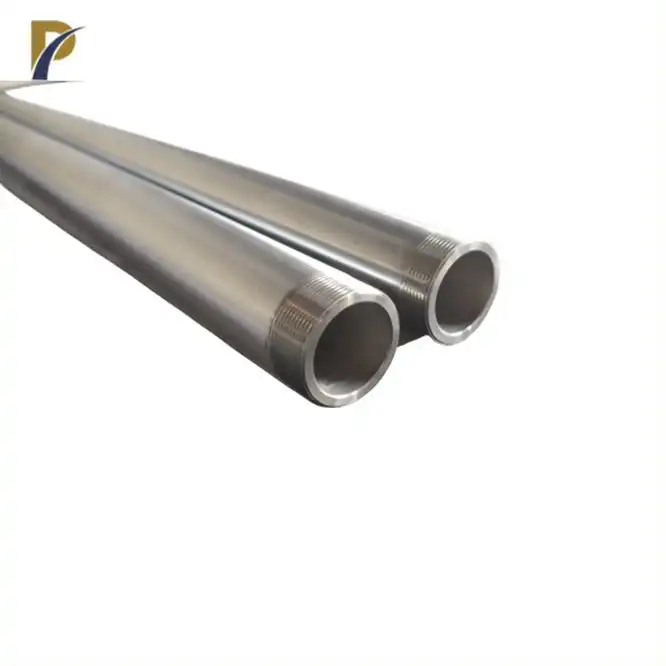

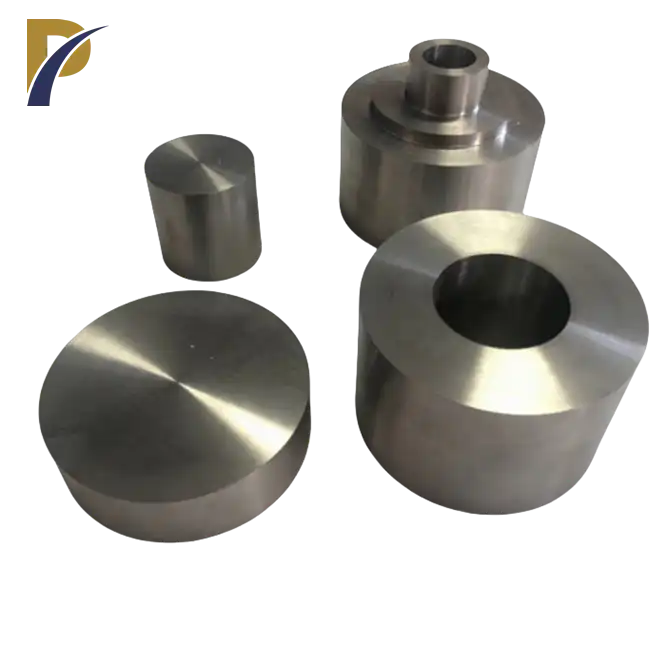

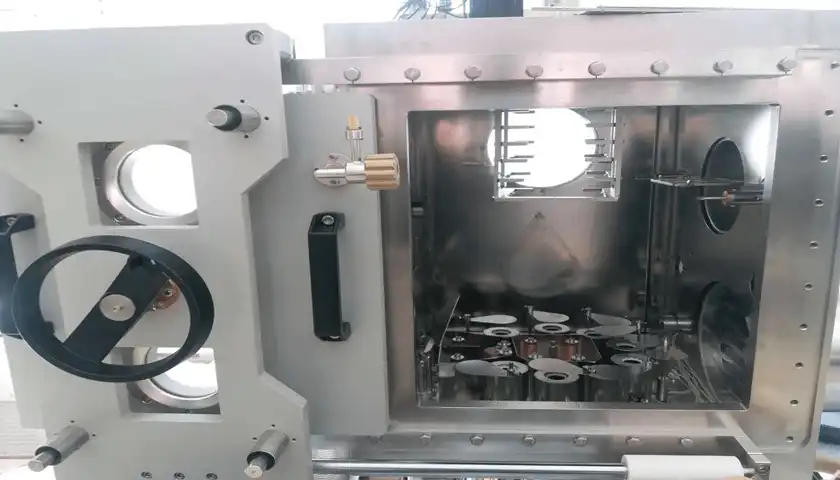

Our Factory:

Shaanxi Peakrise Metal Co., Ltd. operates advanced manufacturing facilities equipped with cutting-edge technology. Our factory houses a variety of production equipment, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, plasma electron beam melting systems, and more. With a focus on quality and precision, we maintain strict quality control procedures to ensure that our products meet international standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging:

- Wooden Box Packaging

- Foam-Filled Cartons

- Waterproof and Moisture-Proof Packaging

- Custom Packaging Available

|

|

|

|

|

|

|

|

Logistics Options:

- Sea Freight

- Air Freight

- Land Transport

- Multimodal Transport

- Express Delivery Services

Why Choose Us?

- Extensive Experience: Shaanxi Peakrise Metal Co., Ltd. has over a decade of experience in non-ferrous metal production, ensuring reliable and consistent product quality.

- Global Reach: Our products are exported to over 10 countries, including the U.S., Germany, and South Korea, with long-term partnerships in place.

- Advanced Technology: We use state-of-the-art equipment to manufacture high-performance molybdenum products tailored to customer needs.

- Customization Services: Our OEM/ODM services allow for product customization based on specific client requirements.

- Quality Assurance: All products are rigorously tested to meet ISO9001 quality standards.

OEM/ODM Services:

Shaanxi Peakrise Metal Co., Ltd. offers extensive OEM and ODM services, allowing clients to customize the dimensions, material composition, and surface finishes of molybdenum evaporation boats. Our team is equipped to meet unique project requirements and deliver high-quality solutions.

|

|

|

|

|

|

|

|

|

FAQ:

- What is the maximum operating temperature of your molybdenum evaporation boats?

- Our molybdenum evaporation boats can operate at temperatures up to 1700°C.

- Can I request custom dimensions for my order?

- Yes, we offer full customization services to meet your specific needs.

- How do you ensure the purity of molybdenum?

- We source high-purity molybdenum (99.95%) and conduct thorough testing to ensure quality.

- What are your packaging options?

- We offer wooden boxes, foam-filled cartons, and moisture-proof packaging to protect the products during shipment.

- What shipping options are available?

- We provide sea freight, air freight, land transport, and express delivery options.

Contact Us (CTA):

Interested in enhancing your production with high-quality molybdenum evaporation boats? Contact Shaanxi Peakrise Metal Co., Ltd. for reliable, durable, and customizable products. Reach out to us today at info@peakrisemetal.com and let’s discuss how we can meet your industrial needs.