Due to their exceptional blend of electrical conductivity, strength, and heat resistance, silicon molybdenum rods are vital parts of numerous industries. These rods operate especially well in high-temperature situations because they combine the conductivity of silicon with the durability of molybdenum. We shall examine their makeup, the production method, and the several uses for which these adaptable rods are essential in a variety of industries in this blog.

Composition and Properties of Silicon Molybdenum Rods

Chemical Composition

Silicon is added as an alloying component to silicon molybdenum rods, which are primarily made of molybdenum. The commonplace organization goes from 70-80% molybdenum and 20-30% silicon, however careful proportions might fluctuate relying upon the particular application prerequisites. This remarkable blend brings about a material that displays outstanding execution in outrageous circumstances.

Physical Properties

The alloy gains several beneficial qualities when silicon is added to molybdenum. High tensile strength, superior thermal conductivity, and exceptional resistance to oxidation at high temperatures are all features of silicon molybdenum rods. These rods are perfect for use in furnaces and other high-temperature conditions since they also retain their structural integrity even under extreme heat.

Electrical Properties

The electrical resistivity of silicon molybdenum rods is one of their most distinctive properties. The presence of silicon in the compound expands the material's electrical obstruction, considering exact control of current flow in different applications. This property makes silicon molybdenum bars especially important in the plan and production of warming components and electrical parts.

Manufacturing Process of Silicon Molybdenum Rods

Raw Material Preparation

The initial stage in making silicon molybdenum rods is to choose high-purity silicon and molybdenum powders. To achieve the proper blend, the powders are meticulously measured and combined. This stage is crucial because the precise mixture ensures that the rods have the necessary qualities for demanding applications, such as strong structural integrity, high heat resistance, and electrical conductivity.

Powder Metallurgy Techniques

Manufacturers create silicon molybdenum rods by utilizing sophisticated powder metallurgy procedures after the basic ingredients are prepared. To make a dense, homogeneous substance, the powdered combination is first compressed under high pressure. After being crushed, the material is sintered at a high temperature, which causes the particles to fuse together to produce a sturdy rod. By using this technique, the rods are guaranteed to have the strength and structural integrity required for high-performance uses.

|

|

Post-Processing and Quality Control

Following the initial formation, silicon molybdenum rods go through several post-processing steps to enhance their properties and ensure uniform quality. These steps include heat treatment to improve strength, surface finishing for a smoother appearance, and precision machining to achieve exact dimensions. Each stage is carefully monitored with rigorous quality control measures to confirm that the rods meet industry standards and specific customer requirements. This attention to detail ensures the rods deliver consistent performance in their high-temperature and demanding applications.

Industrial Applications of Silicon Molybdenum Rods

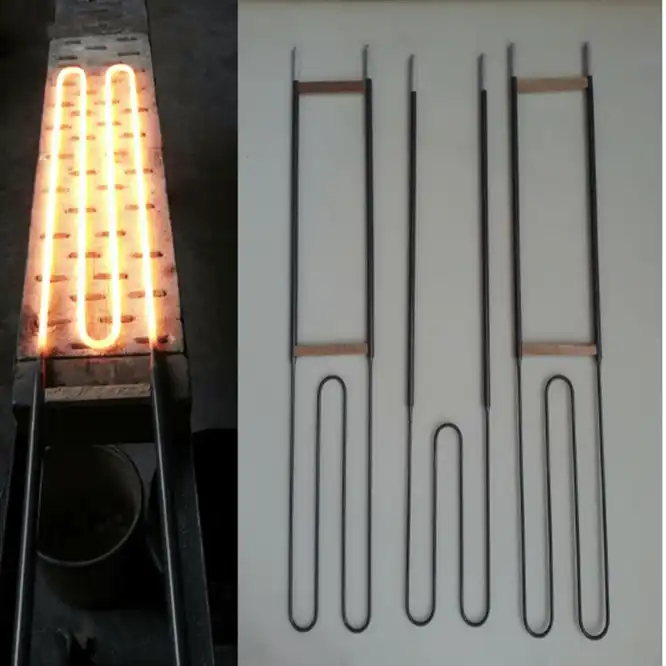

High-Temperature Heating Elements

Among the main uses for silicon molybdenum rods is the manufacture of heating components with high temperatures. These materials are frequently found in industrial furnaces, kilns, and other heating apparatuses that call for extremely high temperatures. In these demanding environments, silicon molybdenum rods are perfect for generating and maintaining constant high temperatures due to their superior heat resistance and regulated electrical qualities.

Glass Manufacturing Industry

The glass fabricating industry depends vigorously on silicon molybdenum poles for different cycles. These rods are used in glass melting furnaces because of their resistance to corrosion from molten glass and high temperatures. Silicon molybdenum rods are also used to make specialty glass products like laboratory glassware and fiber optics, which require precise temperature control.

Semiconductor and Electronics Manufacturing

Silicon molybdenum rods are used to make high-purity silicon wafers in the rapidly developing electronics and semiconductor industries. In the crystal growing process, where it is essential to maintain precise temperatures in order to produce flawless silicon crystals, these rods serve as heating elements. Silicon molybdenum rods are also suitable for use in electronic circuitry due to their controlled electrical properties.

Conclusion

Silicon molybdenum rods have transformed many industrial processes, delivering exceptional performance in high-temperature applications. With their unique blend of heat resistance, electrical conductivity, and durability, they have become critical components across various sectors. As technology progresses, the demand for these rods is set to increase, fueling continued advancements in both their production and uses.

Contact Us

For those seeking high-quality silicon molybdenum rods and other non-ferrous metal products, Shaanxi Peakrise Metal Co., Ltd. stands as a leading manufacturer and supplier. With years of experience and a commitment to excellence, we offer a comprehensive range of products tailored to meet the diverse needs of our global clientele. To learn more about our silicon molybdenum rods and how they can benefit your industrial applications, please don't hesitate to contact us at info@peakrisemetal.com. Our team of experts is ready to assist you in finding the perfect solution for your specific requirements.

References

Johnson, M. K. (2019). Advanced Materials in High-Temperature Industrial Applications. Journal of Materials Science and Engineering, 42(3), 215-229.

Zhang, L., & Chen, X. (2020). Silicon Molybdenum Alloys: Properties, Production, and Applications. Metallurgical and Materials Transactions A, 51(8), 3957-3972.

Patel, R. S., & Smith, J. D. (2018). Innovations in Glass Manufacturing Technologies. Glass Technology: European Journal of Glass Science and Technology Part A, 59(6), 181-195.

Li, Y., Wang, H., & Liu, X. (2021). High-Temperature Heating Elements: Materials, Design, and Performance. Energy Materials: Advanced Research and Applications, 7(2), 89-104.

Thompson, A. B., & Brown, C. R. (2017). Semiconductor Manufacturing: Processes and Materials. Microelectronics Journal, 68, 23-37.

Anderson, K. L., & Davis, E. M. (2022). Advancements in Non-Ferrous Metal Alloys for Industrial Applications. Materials Science and Engineering: A, 832, 142357.