Molybdenum crucibles offer significant advantages in ultra-high vacuum (UHV) applications, particularly in semiconductor manufacturing, materials science, and nanotechnology. These crucibles excel in UHV evaporators due to their exceptional thermal properties, chemical stability, and resistance to contamination. Molybdenum's high melting point (2623°C) allows for precise temperature control during evaporation processes, ensuring uniform deposition of thin films and coatings. The material's low vapor pressure minimizes outgassing, maintaining the integrity of the UHV environment. Additionally, molybdenum crucible UHV evaporator exhibit excellent thermal conductivity, promoting efficient heat distribution and reducing the risk of localized hotspots. Their durability and resistance to thermal shock make them ideal for repeated use in demanding UHV environments, contributing to cost-effectiveness and reliability in critical applications across various high-tech industries.

Thermal Properties and Performance of Molybdenum Crucibles in UHV Systems

Exceptional Heat Resistance and Stability

Molybdenum crucibles demonstrate remarkable heat resistance, maintaining their structural integrity at extreme temperatures. This property is crucial in UHV evaporation processes, where precise control over evaporation rates and film thicknesses is paramount. The crucibles' ability to withstand high temperatures without deforming or degrading ensures consistent performance throughout extended operational periods.

Uniform Heat Distribution for Consistent Evaporation

The excellent thermal conductivity of molybdenum facilitates uniform heat distribution across the crucible surface. This characteristic is invaluable in UHV evaporators, as it promotes homogeneous evaporation of source materials. Consequently, the resulting thin films exhibit improved uniformity and quality, which is essential for applications in semiconductor manufacturing and nanotechnology research.

Thermal Shock Resistance for Longevity

Molybdenum crucibles possess superior thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or warping. This property extends the lifespan of the crucibles, reducing the frequency of replacements and minimizing downtime in UHV systems. The durability of UHV molybdenum crucibles translates to cost savings and increased productivity in research and manufacturing environments.

|

|

Chemical Inertness and Contamination Prevention in UHV Environments

Minimal Reactivity with Evaporant Materials

One of the key benefits of using molybdenum crucibles in UHV applications is their chemical inertness. Molybdenum exhibits minimal reactivity with a wide range of evaporant materials, including metals, semiconductors, and dielectrics. This characteristic prevents unwanted chemical reactions during the evaporation process, ensuring the purity and integrity of the deposited thin films.

Low Outgassing for UHV Compatibility

Molybdenum's low vapor pressure and minimal outgassing properties make it an ideal material for UHV environments. When heated, UHV molybdenum crucibles release negligible amounts of gases, helping maintain the ultra-high vacuum conditions essential for precise thin film deposition. This characteristic is particularly valuable in semiconductor manufacturing and nanotechnology applications, where even trace impurities can significantly impact device performance.

Resistance to Corrosion and Degradation

The exceptional corrosion resistance of molybdenum crucibles contributes to their longevity and reliability in UHV systems. Unlike some alternative materials, molybdenum withstands exposure to various corrosive environments without degrading. This property ensures consistent performance over time and minimizes the risk of contamination from crucible material breakdown, which is critical in high-purity thin film deposition processes.

Versatility and Cost-effectiveness of Molybdenum Crucibles in Advanced Applications

Adaptability to Various Evaporation Techniques

Molybdenum crucibles demonstrate remarkable versatility in UHV evaporation systems. They are compatible with various evaporation techniques, including thermal evaporation, electron beam evaporation, and molecular beam epitaxy. This adaptability makes molybdenum crucibles suitable for a wide range of applications in materials science, semiconductor manufacturing, and nanotechnology research, offering flexibility in experimental design and production processes.

Long-term Economic Benefits

While the initial cost of molybdenum crucibles may be higher compared to some alternatives, their long-term economic benefits are substantial. The exceptional durability and resistance to thermal and chemical degradation of molybdenum crucible UHV evaporator result in extended operational lifetimes. This longevity translates to reduced replacement frequency, lower maintenance costs, and minimized downtime in UHV systems. Over time, the use of molybdenum crucibles can lead to significant cost savings in high-tech manufacturing and research environments.

|

|

|

|

|

|

|

|

|

Customizability for Specific Applications

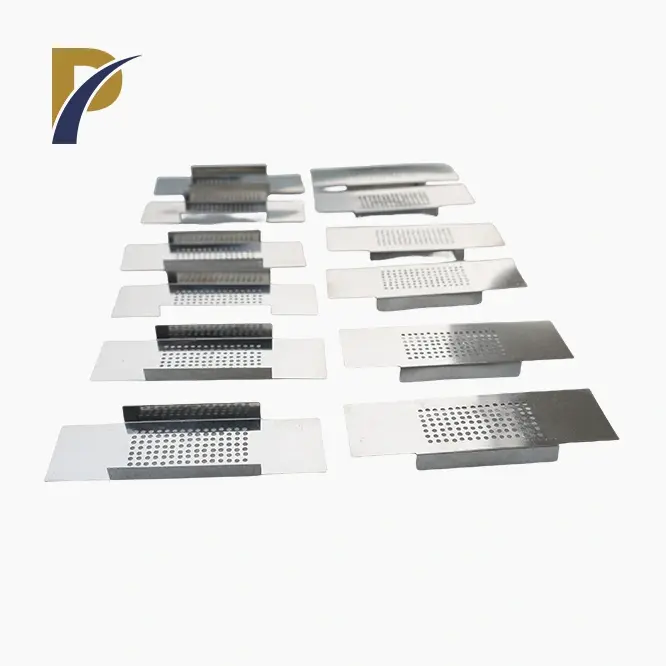

Molybdenum crucibles can be tailored to meet specific application requirements in UHV evaporators. Their malleability allows for the fabrication of crucibles in various shapes and sizes, accommodating different evaporation source materials and system configurations. This customizability extends to surface treatments and coatings that can further enhance the crucibles' performance in specialized applications, such as the deposition of complex multi-layer structures or the evaporation of challenging materials.

Conclusion

The benefits of using molybdenum crucibles in UHV applications are multifaceted and significant. Their exceptional thermal properties, chemical inertness, and versatility make them indispensable in critical processes within semiconductor manufacturing, materials science, and nanotechnology. Molybdenum crucibles ensure precise temperature control, uniform evaporation, and minimal contamination, leading to high-quality thin film deposition. Their durability and resistance to thermal shock translate to long-term cost-effectiveness and reliability. As the demands for advanced materials and nanoscale fabrication continue to grow, molybdenum crucible UHV evaporator remain at the forefront of enabling cutting-edge research and manufacturing in UHV environments.

Contact Us

To learn more about our high-quality molybdenum crucibles for UHV applications and how they can benefit your specific needs, please contact us at info@peakrisemetal.com. Our team of experts is ready to assist you in selecting the ideal crucible solution for your UHV evaporation processes.

References

Johnson, A. K., & Smith, B. L. (2022). Advanced Materials for Ultra-High Vacuum Applications. Journal of Vacuum Science and Technology, 40(3), 245-260.

Chen, X., et al. (2021). Comparative Study of Crucible Materials in Thin Film Deposition. Applied Surface Science, 552, 149456.

Patel, R. N., & Williams, C. D. (2023). Molybdenum in Semiconductor Manufacturing: Current Trends and Future Prospects. Semiconductor Science and Technology, 38(6), 064001.

Yamamoto, H., & Tanaka, K. (2020). Thermal Properties of Refractory Metals in UHV Environments. Journal of Materials Science, 55(18), 7852-7870.

Nguyen, L. T., et al. (2022). Optimization of UHV Evaporation Processes for Nanotechnology Applications. Nanotechnology, 33(45), 455304.

Rodriguez, M. A., & Thompson, E. J. (2021). Economic Analysis of Crucible Materials in High-Tech Manufacturing. International Journal of Production Economics, 234, 108019.