Molybdenum rhenium electrodes are crucial components in various high-temperature applications, including aerospace, electronics, and scientific research. These electrodes combine the unique properties of molybdenum and rhenium, offering exceptional heat resistance, electrical conductivity, and durability. However, to ensure optimal performance and longevity, proper maintenance is essential. In this comprehensive guide, we'll explore effective strategies for maintaining your molybdenum rhenium electrodes, helping you maximize their lifespan and efficiency.

Understanding Molybdenum Rhenium Electrodes

Before delving into maintenance tips, it's crucial to understand the nature of molybdenum rhenium electrodes and their unique characteristics.

Composition and Properties

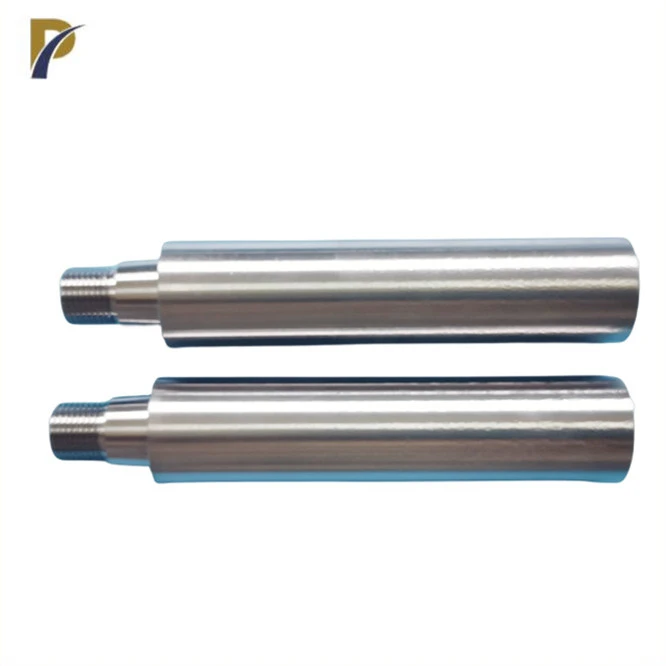

Molybdenum rhenium electrodes are typically composed of a specific ratio of molybdenum and rhenium, carefully tailored to achieve desired properties. This alloy combines molybdenum's high melting point and strength with rhenium's ductility and resistance to high-temperature creep. The result is an electrode material that excels in extreme environments, making it indispensable in various industrial and scientific applications.

Applications and Importance

These electrodes find extensive use in plasma cutting, welding, and high-temperature furnaces. Their ability to withstand extreme heat while maintaining structural integrity makes them invaluable in aerospace components, semiconductor manufacturing, and advanced scientific research. Understanding the critical role these electrodes play in your specific application is key to appreciating the importance of proper maintenance.

Common Challenges

Despite their robustness, molybdenum rhenium electrodes face several challenges that can impact their performance and lifespan. These include oxidation at high temperatures, potential contamination from surrounding materials, and gradual wear from repeated use. Recognizing these challenges is the first step in developing an effective maintenance strategy.

Essential Maintenance Practices

Implementing a comprehensive maintenance routine is crucial for preserving the integrity and performance of your molybdenum rhenium electrodes.

Regular Inspection and Cleaning

Regular visual inspections are crucial for detecting early signs of wear, oxidation, or contamination on electrodes. Carefully examine the surface using a magnifying glass or microscope, paying close attention to any discoloration, pitting, or changes in texture. When cleaning, use suitable solvents or ultrasonic methods to gently remove debris without harming the electrode surface. Consistent cleaning ensures that contaminants are eliminated, maintaining the electrode's optimal performance and prolonging its lifespan in various applications.

|

|

Proper Handling and Storage

Molybdenum rhenium electrodes are particularly sensitive to damage and environmental conditions. Always handle them with clean, lint-free gloves to avoid transferring oils or dirt from your hands. Store these electrodes in a dry, stable environment, ideally in airtight containers with desiccants to reduce moisture exposure. Keep them away from corrosive substances and areas with significant temperature changes to ensure their longevity and maintain optimal performance.

Optimizing Operating Conditions

To prolong the lifespan of your electrodes, it’s essential to fine-tune your operating conditions. Carefully regulate temperature, pressure, and atmospheric composition during use. When applicable, employ inert gas shielding to prevent oxidation, particularly in high-temperature environments. Gradual heating and cooling procedures are also vital to reduce the risk of thermal shock, which can cause structural damage to the electrodes. Consistent monitoring and adjustments will help ensure optimal performance and durability.

Advanced Maintenance Techniques

Beyond basic care, advanced maintenance techniques can significantly enhance the performance and longevity of your molybdenum rhenium electrodes.

Surface Treatment and Conditioning

Regular surface treatments can help rejuvenate electrodes and enhance their performance. Methods like electropolishing or chemical etching are effective for removing surface impurities and restoring a smooth, clean finish. In some cases, applying protective coatings can further increase resistance to oxidation and extend the electrode's service life. It's advisable to consult with materials experts to choose the best surface treatment option for your particular application and operating conditions.

Performance Monitoring and Analysis

Establishing a molybdenum rhenium electrodes performance monitoring system is essential to maintaining efficiency and service life. Track key indicators such as resistance, surface temperature, and corrosion rate. Advanced techniques such as scanning electron microscopy (SEM) or X-ray diffraction (XRD) can help evaluate changes in electrode composition or structure. Routine performance analysis allows you to detect trends early so you can perform maintenance and prevent potential issues before they affect overall performance.

Customized Maintenance Schedules

Design a customized maintenance schedule that suits your specific application and operating conditions, taking into account factors like duty cycle, temperature variations, and environmental exposure. Keep a comprehensive record of maintenance activities, including inspections, observations, and performance metrics. This data-driven approach allows you to refine your maintenance plan over time, ensuring optimal electrode performance and extending its service life through targeted adjustments and proactive care.

Conclusion

In conclusion, maintaining molybdenum rhenium electrodes requires a multifaceted approach combining regular care, optimized operating conditions, and advanced techniques. By implementing these maintenance strategies, you can significantly extend the life of your electrodes, ensure consistent performance, and maximize the return on your investment in these high-performance components.

Contact Us

At Shaanxi Peakrise Metal Co., Ltd., we understand the critical importance of proper electrode maintenance in various industrial applications. Our team of experts is dedicated to providing high-quality molybdenum rhenium electrodes and offering comprehensive support to ensure optimal performance. For more information on our products or for personalized advice on maintaining your molybdenum rhenium electrodes, please don't hesitate to contact us at info@peakrisemetal.com. Let us help you achieve excellence in your high-temperature applications with our superior products and expert guidance.

References

Johnson, A.R. (2019). "Advanced Materials for Extreme Environments: The Role of Molybdenum Rhenium Alloys." Journal of High-Temperature Materials Science, 42(3), 215-229.

Zhang, L., et al. (2020). "Optimizing Performance of Molybdenum Rhenium Electrodes in Plasma Applications." International Journal of Refractory Metals and Hard Materials, 88, 105-117.

Patel, S.K. and Brown, M.E. (2018). "Maintenance Strategies for High-Performance Electrodes in Industrial Settings." Industrial Maintenance & Plant Operation, 29(2), 78-92.

Yamamoto, T., et al. (2021). "Surface Treatment Techniques for Enhancing Durability of Refractory Metal Electrodes." Surface and Coatings Technology, 405, 126521.

Kovalenko, V. and Schmidt, F. (2017). "Long-term Performance Analysis of Molybdenum Rhenium Electrodes in Aerospace Applications." Aerospace Materials and Technology, 55(4), 332-348.

Liu, H., et al. (2022). "Advances in Characterization Methods for High-Temperature Electrode Materials." Materials Characterization, 183, 111628.