Understanding Molybdenum Properties and Welding Challenges

This guide explores the unique properties of molybdenum, including its high melting point and strength at elevated temperatures. We also discuss common challenges faced during welding, such as heat control, distortion, and choosing the appropriate filler materials.

Molybdenum's Distinctive Traits

Molybdenum boasts several remarkable properties that make it invaluable in numerous applications. Its high melting point of 2,623°C (4,753°F) enables it to withstand extreme temperatures, making it ideal for use in furnace components and high-temperature structural applications. The metal's excellent thermal conductivity allows for efficient heat distribution, while its low coefficient of thermal expansion minimizes distortion during temperature fluctuations.

Oxidation Sensitivity and Embrittlement

One of the primary challenges when welding molybdenum plates is the metal's susceptibility to oxidation at elevated temperatures. When exposed to oxygen during welding, molybdenum rapidly forms oxides that can compromise the weld's integrity and lead to embrittlement. This sensitivity necessitates strict control of the welding environment to prevent contamination and ensure optimal results.

Recrystallization and Grain Growth

Another critical factor to consider is molybdenum's tendency to undergo recrystallization and grain growth when subjected to high temperatures during welding. This phenomenon can significantly alter the metal's mechanical properties, potentially leading to reduced strength and increased brittleness in the welded area. Careful control of heat input and cooling rates is essential to mitigate these effects and maintain the desired material properties.

Preparation Techniques for Successful Molybdenum Plate Welding

Proper preparation is paramount to achieving high-quality welds with molybdenum plates. By following these essential steps, you can set the stage for a successful welding process.

Surface Cleaning and Contamination Prevention

Thoroughly clean the molybdenum plates before welding to remove any surface contaminants, such as oils, greases, or oxides. Use a combination of mechanical cleaning methods, like wire brushing or abrasive blasting, followed by chemical cleaning with appropriate solvents. Pay special attention to the areas adjacent to the weld joint, as any impurities can compromise weld quality.

Joint Design Optimization

Selecting the appropriate joint design is crucial for molybdenum plate welding. Due to the metal's high thermal conductivity and potential for oxidation, it's advisable to use narrow gap joints or beveled edges to minimize heat input and exposure to atmospheric oxygen. Consider employing computer-aided design (CAD) software to optimize joint geometry and ensure proper fit-up before welding.

Preheating Considerations

Preheating molybdenum plates can help reduce thermal shock and minimize the risk of cracking during welding. The preheating temperature typically ranges from 150°C to 300°C (302°F to 572°F), depending on the plate thickness and specific application requirements. Use induction heating or resistive heating methods to achieve uniform temperature distribution across the plates.

|

|

Advanced Welding Techniques for Molybdenum Plates

By employing these advanced methods, you can achieve superior weld quality and performance.

Gas Tungsten Arc Welding (GTAW) for Precision

Gas Tungsten Arc Welding, also known as TIG welding, is the preferred method for joining molybdenum plates due to its precise heat control and ability to produce high-quality, contamination-free welds. When performing GTAW on molybdenum, use a pure tungsten electrode and argon shielding gas to prevent oxidation. Employ a pulsed current technique to minimize heat input and control the weld pool, reducing the risk of distortion and grain growth.

Electron Beam Welding for Complex Geometries

For applications requiring deep penetration or welding of complex geometries, electron beam welding (EBW) offers unparalleled precision and control. This process takes place in a vacuum chamber, eliminating the risk of atmospheric contamination and allowing for extremely narrow and deep welds. EBW is particularly advantageous for joining thick molybdenum plates or creating hermetic seals in specialized components.

Laser Welding for Automation and Speed

Laser welding has gained popularity in molybdenum plate joining due to its high speed, automation potential, and ability to produce narrow, deep welds with minimal heat-affected zones. When employing laser welding, use a high-power fiber or CO2 laser with precise beam control to achieve optimal results. Implement a shielding gas system to protect the weld pool and surrounding areas from oxidation during the process.

Post-Weld Treatment and Quality Assurance

The welding process doesn't end when the arc is extinguished. Proper post-weld treatment and rigorous quality assurance measures are essential to ensure the longevity and performance of molybdenum plate welds.

Stress Relief and Annealing Procedures

After welding, molybdenum plates may require stress relief or annealing treatments to alleviate residual stresses and restore optimal mechanical properties. Conduct these heat treatments in a controlled atmosphere furnace to prevent oxidation. Typical stress relief temperatures range from 800°C to 1,200°C (1,472°F to 2,192°F), with holding times varying based on plate thickness and specific application requirements.

Non-Destructive Testing Methods

Employ a combination of non-destructive testing (NDT) techniques to evaluate the integrity of molybdenum plate welds. Radiographic testing (RT) can reveal internal defects, while ultrasonic testing (UT) is effective for detecting subsurface flaws. Liquid penetrant testing (PT) or magnetic particle testing (MT) can be used to identify surface discontinuities. Select the most appropriate NDT methods based on the specific welding application and quality standards.

Microstructural Analysis and Mechanical Testing

To gain a comprehensive understanding of weld quality and performance, conduct microstructural analysis and mechanical testing on representative samples. Metallographic examination can reveal grain structure, potential defects, and the extent of the heat-affected zone. Perform tensile tests, bend tests, and hardness measurements to verify that the welded joints meet the required mechanical specifications for their intended application.

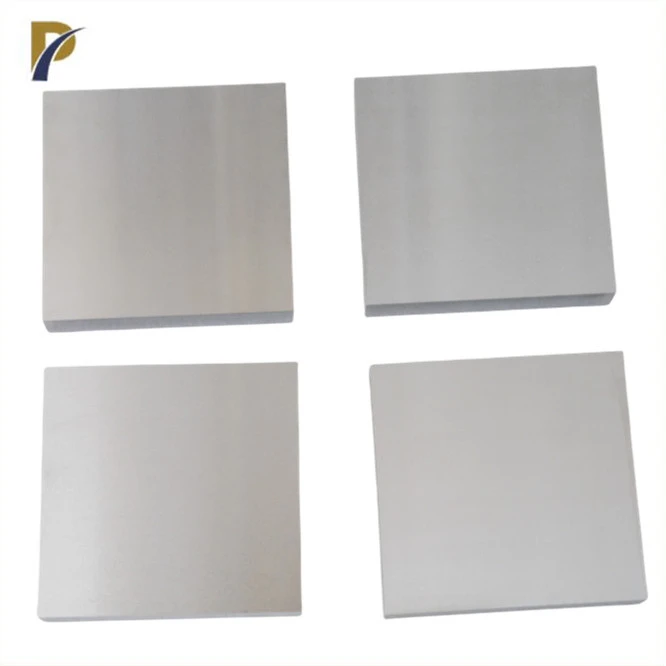

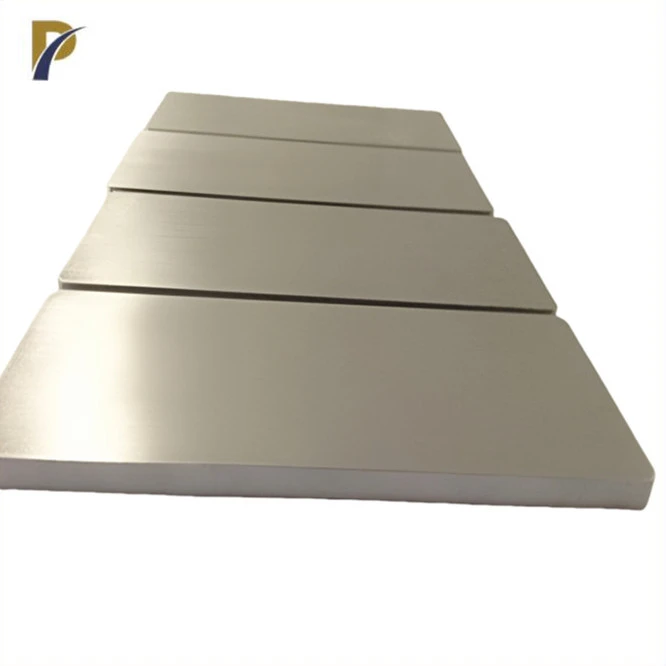

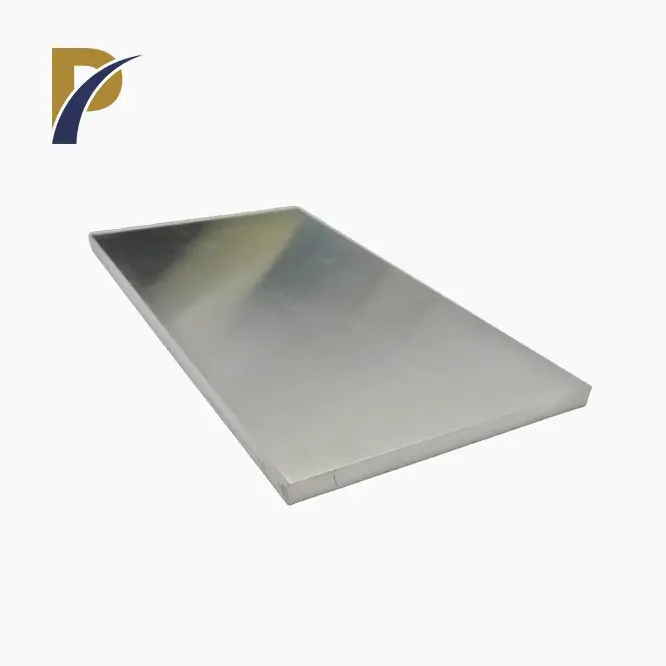

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

Conclusion

By understanding the unique properties of molybdenum plates, implementing proper preparation procedures, and employing cutting-edge welding methods, you can achieve exceptional results in joining these valuable metal plates. Remember that continuous learning and practice are key to perfecting your skills in this challenging yet rewarding field of welding technology.

Contact Us

Are you looking for high-quality molybdenum plates or expert guidance on welding techniques? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com to discover how our comprehensive range of non-ferrous metal products and services can meet your specific needs.