Sapphire crucible molybdenum plays a crucial role in various high-tech industries, from semiconductor manufacturing to advanced materials production. These specialized crucibles are designed to withstand extreme temperatures and harsh chemical environments, making them indispensable for many critical processes. However, to maximize their efficiency and longevity, it's essential to implement proper care and maintenance strategies. By understanding the unique properties of sapphire molybdenum crucibles and adopting best practices for their use and upkeep, you can significantly extend their lifespan, improve performance, and reduce operational costs. In this comprehensive guide, we'll explore expert techniques and insider tips to help you get the most out of your sapphire crucible molybdenum investments.

Understanding Sapphire Crucible Molybdenum Properties

Composition and Structure

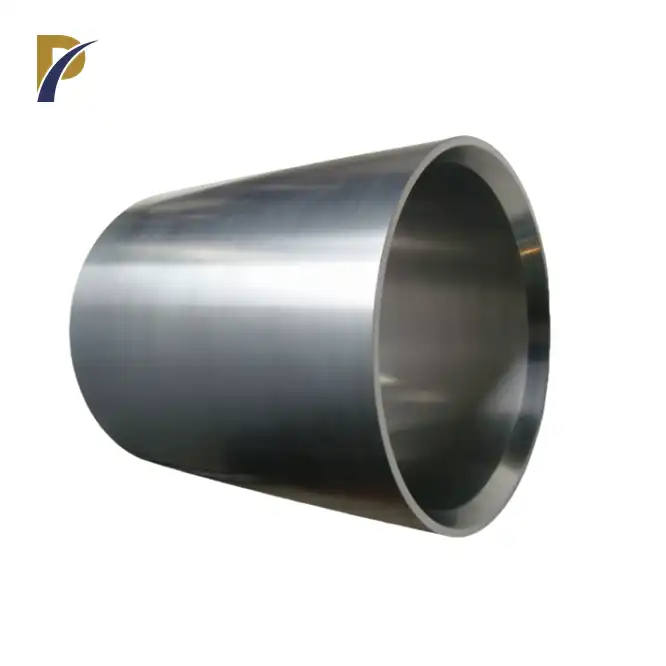

Sapphire crucible molybdenum is a sophisticated composite material that combines the exceptional hardness and chemical inertness of sapphire with the high-temperature strength and thermal conductivity of molybdenum. The sapphire component, typically in the form of a thin-walled crucible, is grown as a single crystal of aluminum oxide (Al2O3). This structure ensures unparalleled purity and resistance to chemical attack. The molybdenum backing provides mechanical support and enhances heat distribution, creating a synergistic blend of properties ideal for demanding applications.

Thermal Characteristics

One of the most remarkable features of sapphire molybdenum crucibles is their ability to withstand extreme temperatures. The melting point of sapphire exceeds 2000°C, while molybdenum boasts a melting point of approximately 2620°C. This thermal stability allows these crucibles to maintain their integrity in high-temperature processes where other materials would fail. Additionally, the thermal expansion coefficient of sapphire is relatively low, which helps minimize stress and potential cracking during rapid temperature changes.

Chemical Resistance

The sapphire component of these crucibles exhibits exceptional resistance to a wide range of chemicals, including acids, bases, and corrosive gases. This chemical inertness is particularly valuable in semiconductor and optoelectronic manufacturing, where even trace impurities can have significant impacts on product quality. The molybdenum backing, while less chemically resistant than sapphire, still offers good protection against many reactive substances, especially in reducing atmospheres.

|

|

Optimal Usage Practices for Longevity

Temperature Management

While sapphire crucible molybdenum can withstand extreme temperatures, proper temperature management is crucial for maximizing lifespan. Gradual heating and cooling cycles help prevent thermal shock, which can lead to micro-cracks or delamination between the sapphire and molybdenum layers. Implementing precise temperature control systems and following recommended ramp-up and cool-down procedures can significantly reduce thermal stress on the crucible.

Handling and Storage

Proper handling and storage are essential for maintaining the integrity of sapphire molybdenum crucibles. Always use clean, powder-free gloves when handling these components to prevent contamination. Store crucibles in a clean, dry environment, preferably in dedicated containers that protect them from physical damage and environmental contaminants. Avoid stacking crucibles directly on top of each other, as this can lead to scratches or chips in the sapphire surface.

Cleaning Protocols

Regular cleaning is crucial for removing residues and maintaining the purity of your sapphire crucible molybdenum. Develop a cleaning protocol that's appropriate for your specific application, considering factors such as the materials processed and the operating environment. Ultrasonic cleaning in high-purity solvents, followed by thorough rinsing with deionized water and careful drying, is often effective. For stubborn residues, gentle mechanical cleaning with soft, non-abrasive materials may be necessary, but extreme caution must be exercised to avoid damaging the sapphire surface.

Advanced Maintenance Strategies

Surface Inspection and Analysis

Regular inspection of your sapphire molybdenum crucibles is vital for early detection of wear, damage, or contamination. Implement a schedule for visual inspections using high-magnification microscopy to identify surface defects or changes in appearance. For more detailed analysis, techniques such as X-ray fluorescence (XRF) spectroscopy can be employed to detect trace contaminants on the crucible surface. By establishing baseline measurements and tracking changes over time, you can make informed decisions about when to perform maintenance or replace crucibles.

Protective Coatings and Treatments

In some applications, applying protective coatings or treatments to sapphire crucible molybdenum can enhance longevity and performance. For instance, thin films of refractory metals or ceramics can be deposited on the molybdenum surface to improve corrosion resistance in specific chemical environments. Similarly, surface treatments such as ion implantation or laser texturing can modify the sapphire surface to enhance certain properties or reduce adhesion of process materials. However, these advanced techniques should only be pursued in consultation with materials experts and crucible manufacturers to ensure compatibility with your specific use case.

Environmental Control

The environment in which sapphire molybdenum crucibles operate can significantly impact their lifespan. Maintaining a clean, controlled atmosphere during processing is crucial. This may involve using high-purity process gases, implementing advanced filtration systems, or operating in vacuum conditions. Pay particular attention to the presence of oxygen at high temperatures, as this can lead to accelerated oxidation of the molybdenum component. By carefully managing the processing environment, you can minimize chemical attack and extend the useful life of your crucibles.

Conclusion

Extending the lifespan of your sapphire crucible molybdenum requires a multifaceted approach that combines understanding of material properties, optimal usage practices, and advanced maintenance strategies. By implementing the techniques discussed in this guide, you can significantly enhance the durability and performance of these critical components. Remember that each application may have unique requirements, so it's essential to tailor these strategies to your specific needs. With proper care and attention, sapphire molybdenum crucibles can provide reliable, high-performance operation for extended periods, contributing to improved process efficiency and reduced operational costs.

Contact Us

For more information on sapphire crucible molybdenum and how to optimize its use in your specific application, please don't hesitate to contact our team of experts at Shaanxi Peakrise Metal Co., Ltd. We're here to help you achieve the best possible results with our high-quality products. Reach out to us at info@peakrisemetal.com to discuss your needs and discover how we can support your operations.

References

Dobrovinskaya, E. R., Lytvynov, L. A., & Pishchik, V. (2009). Sapphire: Material, Manufacturing, Applications. Springer Science & Business Media.

Fridman, A. (2008). Plasma Chemistry. Cambridge University Press.

Hearle, J. W. S. (2001). High-performance fibres. Woodhead Publishing.

Khanna, Y. P. (2005). Handbook of Thermal Analysis of Plastics. CRC Press.

Murty, B. S., Yeh, J. W., & Ranganathan, S. (2014). High-Entropy Alloys. Butterworth-Heinemann.

Shatokha, V. (2016). Handbook of Sustainability in Additive Manufacturing: Volume 1. Springer.