Zirconium Wire for Chemical Uses

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Wire for Chemical Uses

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of Zirconium Wire for Chemical Uses, catering to various industries that require high-performance materials. Zirconium, known for its remarkable corrosion resistance and high melting point, is a critical element in numerous chemical applications, particularly in environments that expose materials to aggressive chemicals and high temperatures.

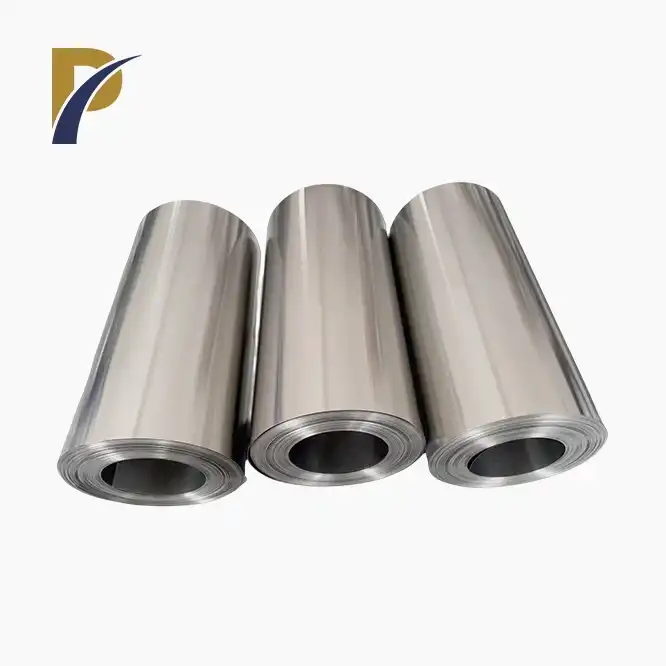

Zirconium wire is utilized extensively in chemical processing, nuclear reactors, and aerospace industries. Its unique properties allow it to maintain structural integrity and performance under extreme conditions. As an advanced non-ferrous metal production enterprise, we prioritize quality and precision in our manufacturing processes. Our zirconium wire is produced with state-of-the-art technology and adheres to stringent international standards, ensuring that our customers receive only the best materials.

At Shaanxi Peakrise Metal Co., Ltd., we have invested in research and development to continually enhance the performance of our zirconium wire. We understand the unique needs of our clients and offer customizable solutions to meet specific requirements. With years of experience in the industry and a commitment to excellence, we have established a reputation for reliability and quality in the global market.

Product Parameters

| Specification | Value |

|---|---|

| Diameter Range | 0.2 mm - 5.0 mm |

| Tensile Strength | ≥ 700 MPa |

| Elongation | ≥ 10% |

| Melting Point | 1855 °C |

| Density | 6.51 g/cm³ |

Physical and Chemical Properties

- Corrosion Resistance: Zirconium wire exhibits excellent resistance to acids, bases, and other corrosive substances, making it ideal for chemical environments.

- High Melting Point: With a melting point of 1855 °C, zirconium can withstand extreme temperatures without deforming.

- Ductility: The ductility of zirconium allows it to be easily formed into wires without compromising strength.

- Thermal Conductivity: Zirconium's thermal conductivity is suitable for applications where heat dissipation is crucial.

|

|

|

Product Functions

-

Corrosion Resistance: The primary function of zirconium wire is its ability to resist corrosion in harsh chemical environments. This property extends the lifespan of equipment and reduces maintenance costs.

-

High-Temperature Performance: With a high melting point, zirconium wire maintains its integrity and performance even at elevated temperatures, making it suitable for applications in chemical processing and nuclear industries.

-

Ductility and Malleability: Zirconium wire can be easily shaped and manipulated, allowing for versatile applications in various industries.

-

Biocompatibility: Zirconium is biocompatible, making it a suitable choice for medical applications, particularly in implants and prosthetics.

Product Applications

-

Chemical Processing: In chemical plants, zirconium wire is used in reactors and piping systems where exposure to corrosive substances is common. Its durability ensures long-term performance.

-

Nuclear Industry: Zirconium is a crucial material in nuclear reactors due to its low neutron absorption cross-section, enhancing reactor efficiency.

-

Aerospace: The aerospace sector employs zirconium wire in engine components and other high-stress applications where heat resistance and structural integrity are paramount.

-

Medical Applications: With its biocompatibility, zirconium wire is increasingly used in medical devices and implants, providing strength and durability without causing adverse reactions.

-

Electronics: Zirconium's properties make it suitable for use in electronic components, enhancing the performance and reliability of devices.

|

|

Product Manufacturing Process

The production of zirconium wire involves several key steps:

-

Raw Material Preparation: High-purity zirconium sponge is selected to ensure the highest quality of the final product.

-

Melting: The zirconium sponge is melted in a vacuum arc melting furnace to eliminate impurities and achieve the desired composition.

-

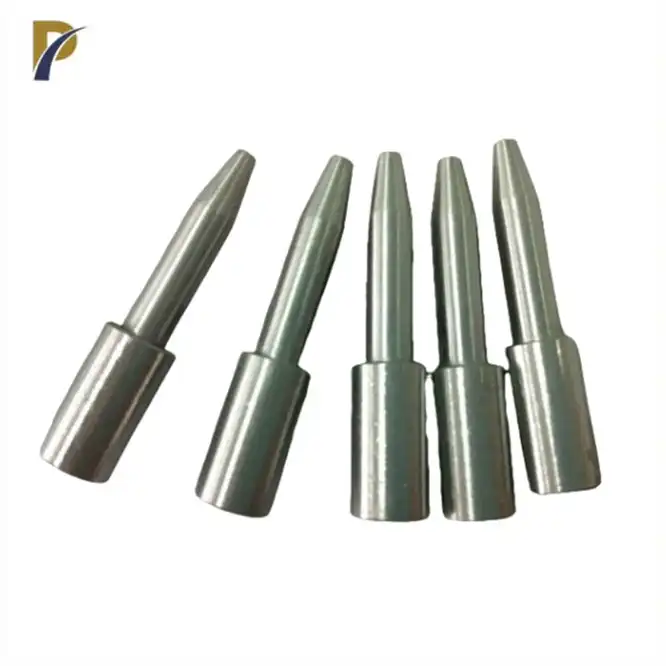

Wire Drawing: The molten zirconium is then drawn into wire through a series of dies to achieve the specified diameter.

-

Annealing: The wire undergoes annealing to relieve internal stresses and improve ductility.

-

Quality Testing: Each batch of wire is rigorously tested for mechanical properties, chemical composition, and dimensional accuracy to ensure compliance with industry standards.

Company Overview

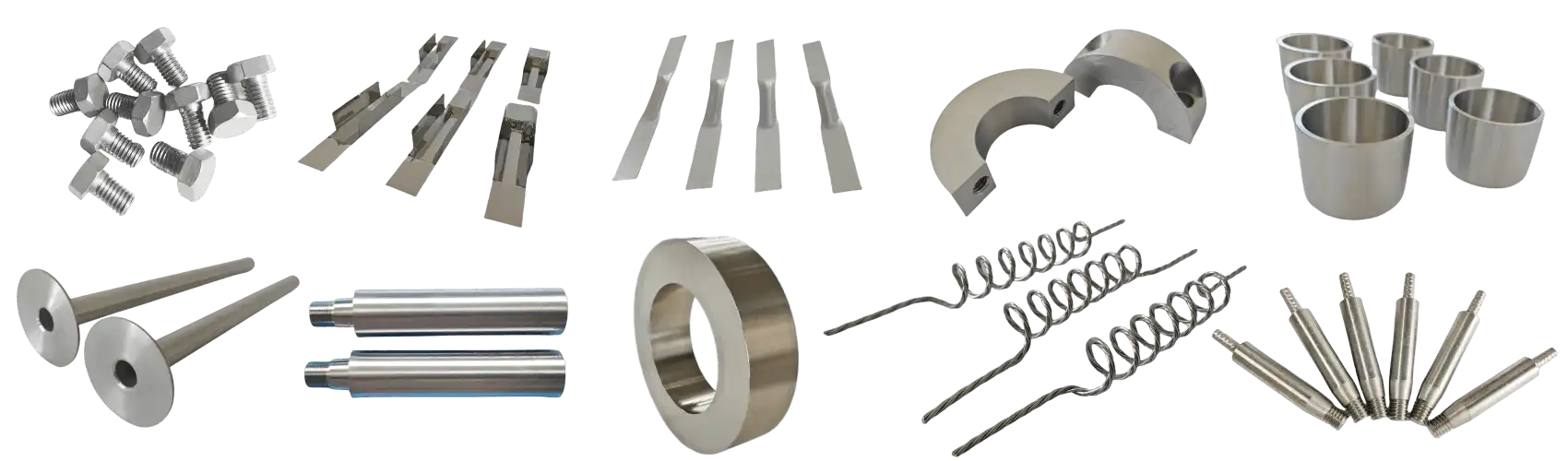

Shaanxi Peakrise Metal Co., Ltd. is a well-established non-ferrous metal production enterprise with extensive experience in the manufacturing of tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel products. We are proud to offer a diverse range of high-quality materials, including tungsten-copper alloys, molybdenum-copper alloys, and various other specialty alloys.

Since our inception in 2010, we have focused on expanding our export business, providing high-quality non-ferrous metal products to the international market. Our commitment to excellence and customer satisfaction has allowed us to build long-term partnerships with clients across the globe, including countries such as Taiwan, South Korea, the United States, and Germany.

Our advanced production facility is equipped with a variety of machinery, including vacuum arc melting furnaces, wire drawing machines, plasma welding equipment, and CNC machines. This state-of-the-art equipment enables us to produce precision-engineered products that meet the highest quality standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

At Shaanxi Peakrise Metal Co., Ltd., we understand the importance of secure and reliable packaging for our products. Our packaging solutions include:

- Wooden Crate Packaging: Durable wooden crates provide maximum protection during transportation.

- Carton Packaging: Lightweight and eco-friendly cartons are used for smaller orders, ensuring safety and ease of handling.

- Foam Filling: Foam fillers are utilized to prevent movement and damage during shipping.

- Waterproof and Moisture-proof Packaging: All products are packaged to withstand moisture, ensuring their integrity upon arrival.

- Custom Packaging: We offer customized packaging solutions to meet specific client requirements and preferences.

- International Standard Packaging: Our packaging adheres to international shipping standards, ensuring compliance and safety.

|

|

|

|

|

|

|

|

|

|

Logistics Options

We offer various logistics options to meet the diverse needs of our clients:

- Sea Freight: Cost-effective shipping for bulk orders, ensuring timely delivery across international waters.

- Air Freight: Fast and reliable air shipping for urgent orders.

- Land Transport: Efficient land transportation for nearby destinations.

- Multimodal Transport: A combination of shipping methods for optimal delivery efficiency.

- Express Services: Quick and convenient delivery options for urgent shipments.

Why Choose Us?

-

Expertise and Experience: With years of experience in non-ferrous metal production, we possess the knowledge and skills necessary to deliver high-quality products.

-

Advanced Technology: Our state-of-the-art production facilities utilize cutting-edge technology to ensure precision and quality in every product.

-

Customized Solutions: We understand that each client has unique needs, which is why we offer tailored solutions to meet specific requirements.

-

Global Reach: Our products are exported to numerous countries, and we have established long-term partnerships with clients around the world.

-

Quality Assurance: Our commitment to quality is unwavering, and we conduct thorough testing to ensure that every product meets the highest standards.

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we are proud to offer OEM and ODM services to our clients. Whether you need customized dimensions, specific packaging requirements, or unique formulations, we have the capabilities to meet your needs. Our dedicated team works closely with clients to develop tailored solutions that align with their project specifications and business objectives.

Frequently Asked Questions (FAQ)

-

What is the tensile strength of zirconium wire?

The tensile strength of our zirconium wire is ≥ 700 MPa. -

What applications can zirconium wire be used for?

Zirconium wire is suitable for chemical processing, nuclear reactors, aerospace applications, and medical devices. -

Can I order custom sizes of zirconium wire?

Yes, we offer OEM services and can produce custom sizes according to your specifications. -

What is the melting point of zirconium?

The melting point of zirconium is 1855 °C. -

How does your company ensure product quality?

We conduct rigorous testing on each batch of zirconium wire to ensure compliance with industry standards and specifications.

Call to Action

At Shaanxi Peakrise Metal Co., Ltd., we are committed to providing high-quality zirconium wire for chemical uses. If you're looking for a reliable supplier that values quality and customer satisfaction, look no further. We invite global buyers to connect with us and explore how we can meet your needs.

Contact Us: For inquiries and collaboration, please reach out to us at info@peakrisemetal.com. Let's work together to achieve excellence in your projects!