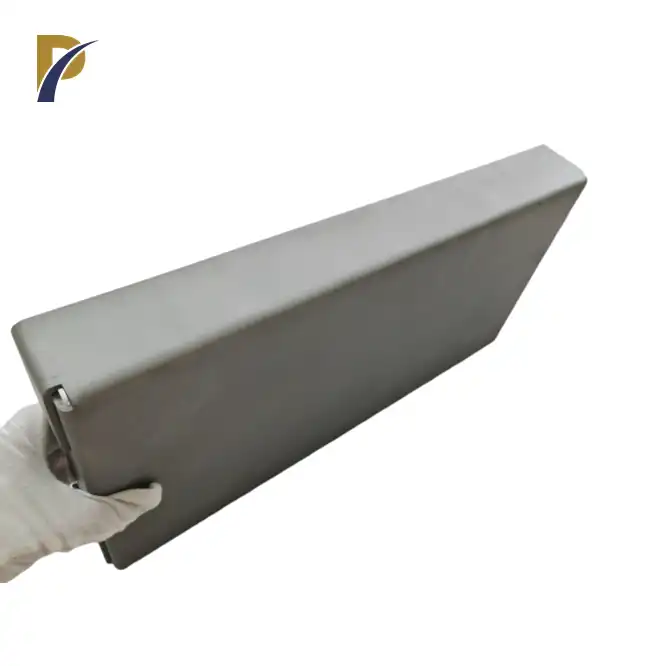

molybdenum boats

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Product Introduction

Molybdenum boats are essential components in industries requiring high-temperature environments, especially for the evaporation and sintering processes. Their ability to withstand extreme heat, corrosion, and chemical reactions makes them ideal for applications such as thin film deposition, coating, and material evaporation in vacuum chambers. Molybdenum’s unique properties allow it to maintain structural integrity and performance under high temperatures, which is why it is favored in demanding industries like electronics, metallurgy, and chemical processing.

As a leading supplier, Shaanxi Peakrise Metal Co., Ltd. provides high-quality molybdenum boats to meet the rigorous standards of the global market. Our molybdenum boats are manufactured from pure molybdenum, which ensures high melting points, excellent conductivity, and resistance to corrosion and oxidation. With over a decade of experience, we pride ourselves on being a trusted supplier of non-ferrous metal products, and our molybdenum boats are no exception. We have a robust production and quality control system that guarantees product consistency and reliability. Our molybdenum boats are exported to countries like the United States, Germany, South Korea, and more, where they are highly regarded for their precision and durability.

Product Parameters Table

| Parameter | Value |

|---|---|

| Material Purity | ≥99.95% molybdenum |

| Operating Temperature | Up to 2600°C |

| Density | 10.2 g/cm³ |

| Thickness | 0.2 mm - 3.0 mm |

| Standard Sizes (L x W x H) | Customized as per request |

| Melting Point | 2620°C |

| Electrical Conductivity | 33.3 nΩ·m at 20°C |

| Thermal Expansion | 4.8 µm/(m·K) at 20°C |

| Grade | Main chemical content% | Impurity content(<%) | |||||||||

| Mo | Ti | Zr | C | La2O3 | C | 0 | N | Fe | Ni | Si | |

| Mo1 | Remain | — | — | — | — | 0.01 | 0.007 | 0.002 | 0.01 | 0.002 | 0.01 |

| TZM | Remain | 0.40~0.55 | 0.06~0.12 | 0.01~0.04 | — | — | 0.03 | 0.002 | 0.01 | 0.005 | 0.005 |

| MoLa | Remain | — | — | — | 0.4~1.2 | 0.01 | — | 0.002 | 0.01 | 0.002 | 0.01 |

Physical and Mechanical Properties

- High Melting Point: Molybdenum has a melting point of 2620°C, allowing the boats to perform reliably in high-temperature applications.

- Thermal Conductivity: Excellent thermal conductivity ensures heat distribution without the risk of deformation or warping.

- Low Thermal Expansion: Molybdenum’s low coefficient of thermal expansion helps maintain structural integrity under fluctuating temperatures.

- Corrosion Resistance: Superior resistance to oxidation and corrosion, making it suitable for harsh environments, especially in vacuum conditions.

|

|

|

Product Functions

- High-Temperature Performance: Molybdenum boats can withstand extreme temperatures, making them perfect for sintering and material evaporation processes in vacuum systems.

- Corrosion Resistance: These boats resist chemical degradation, which is crucial for applications involving reactive chemicals or oxidizing environments.

- Uniform Heat Distribution: The excellent thermal conductivity of molybdenum allows for uniform heat transfer during processes, which ensures consistency in material treatment.

- Cost-Efficiency: Molybdenum boats offer a longer lifespan compared to other materials, reducing operational costs in high-temperature processes.

Product Applications

- Vacuum Coating Systems: Molybdenum boats are widely used in thermal evaporation and thin-film deposition in industries such as optics and electronics.

- Sintering Applications: In metallurgy, molybdenum boats are essential in sintering processes where they withstand prolonged exposure to high temperatures.

- Chemical Processing: Their resistance to chemical corrosion makes molybdenum boats ideal for handling aggressive substances during processing.

- Semiconductor Industry: Molybdenum boats are used for evaporation in semiconductor manufacturing, contributing to the production of thin films and electronic components.

|

|

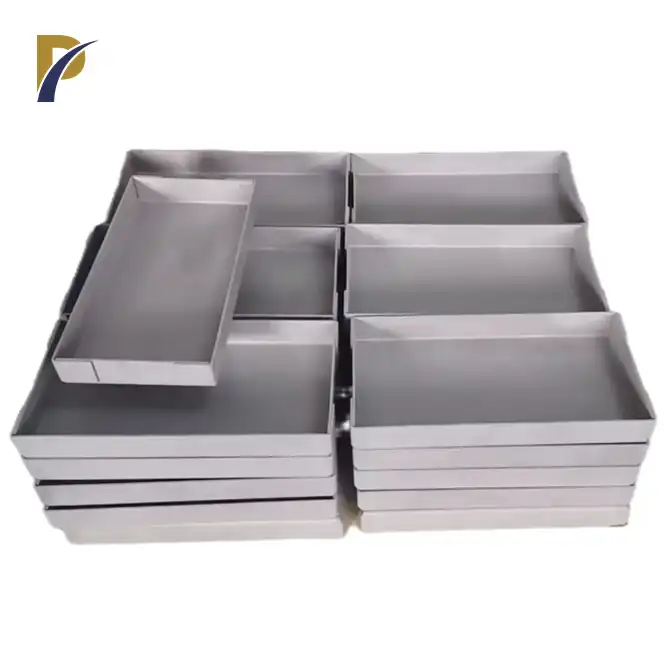

Product Process and Production Flow

Our molybdenum boats are crafted through a series of meticulously controlled processes. First, the raw molybdenum is purified to achieve a high purity level of 99.95%. It is then shaped into flat sheets through a rolling process and finally formed into boats using precision cutting and bending machines. Our advanced equipment, such as vacuum arc melting furnaces and plasma welding rooms, ensures that each product meets the highest industry standards. Every boat undergoes rigorous testing, including dimensional checks, strength testing, and surface inspection, to ensure it meets the specifications required for high-temperature applications.

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art production facility, equipped with a wide range of machinery designed to produce high-quality non-ferrous metal products. We use cutting-edge technologies, including vacuum annealing furnaces, laser cutters, and CNC machines, to ensure that our products are not only precise but also highly reliable. With over 10 years of experience in the production and export of molybdenum and other metals, our factory is a trusted source for industries across the globe.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Box Packaging: Provides sturdy protection during long-distance transportation, ensuring the molybdenum boats remain intact.

- Carton Packaging: Suitable for lighter shipments, offering sufficient protection against minor impacts.

- Foam-Filled Packaging: Prevents damage by securing the product firmly within the packaging, ideal for fragile or complex items.

- Waterproof and Moisture-Proof Packaging: Guarantees that the molybdenum boats are protected from humidity and water damage during transport.

- Custom Packaging: Available upon request to meet specific client needs and comply with international packaging standards.

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: With over a decade of experience, we offer unparalleled expertise in non-ferrous metal production and customization.

- Advanced Equipment: Our factory is equipped with state-of-the-art technology, ensuring precise manufacturing and consistent quality control.

- Global Reach: We have a well-established export network, with long-term partnerships across Europe, Asia, and the Americas.

- Customization Services: We provide OEM and ODM services, allowing customers to request specific product dimensions and characteristics to meet their needs.

- Quality Assurance: We follow strict ISO 9001 standards and implement a robust quality control system to ensure the reliability of every molybdenum boat we produce.

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer full OEM and ODM services to meet our customers’ unique requirements. Whether you need molybdenum boats in custom sizes, specific tolerances, or different packaging options, we are equipped to handle special requests. Our team works closely with clients to ensure that all custom products are manufactured to the highest standards and delivered on time.

|

|

FAQ

-

What are the benefits of using molybdenum boats?

Molybdenum boats offer high resistance to heat and corrosion, making them ideal for high-temperature applications like material evaporation and sintering. -

Can I request a custom size for molybdenum boats?

Yes, we provide customized solutions for molybdenum boats, including specific dimensions, thicknesses, and shapes. -

What is the maximum operating temperature for molybdenum boats?

Our molybdenum boats can operate up to 2600°C without losing structural integrity or performance. -

How are the molybdenum boats tested before shipping?

Each molybdenum boat undergoes rigorous testing, including dimensional checks, material strength tests, and visual inspections for defects. -

What packaging options are available?

We offer various packaging options, including wooden boxes, carton packaging, foam-filled packaging, and waterproof solutions to ensure safe transportation.

Contact Us

For more information about our molybdenum boats and how Shaanxi Peakrise Metal Co., Ltd. can help meet your industrial needs, please contact us at info@peakrisemetal.com. We look forward to collaborating with global purchasers and delivering high-quality molybdenum boats to meet your specific requirements.