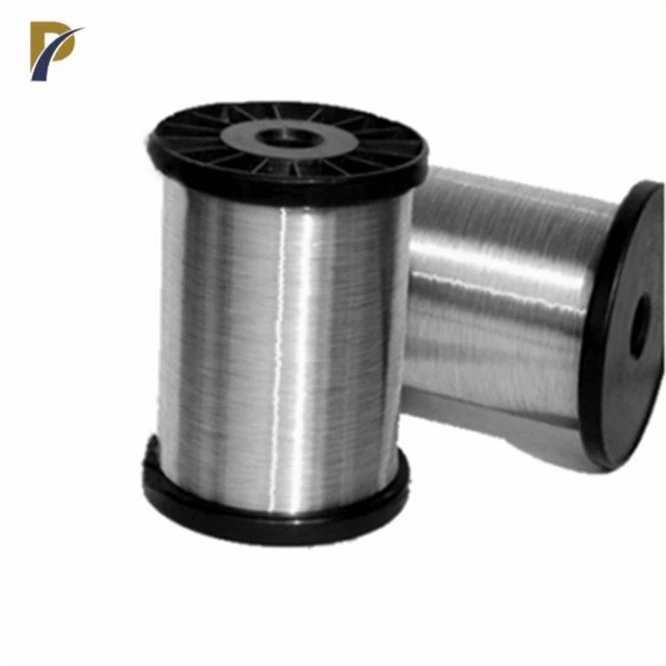

ASTM B550 Zirconium Alloy Wire

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

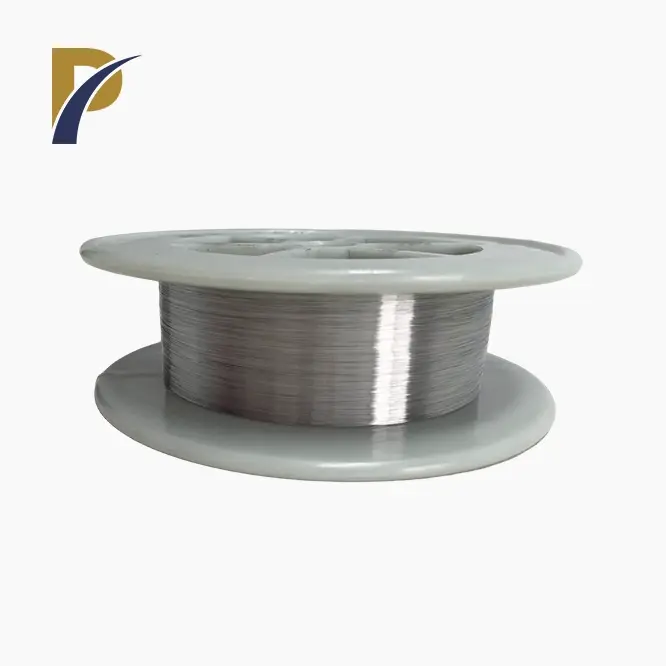

ASTM B550 Zirconium Alloy Wire - High Performance and Reliability from Shaanxi Peakrise Metal Co., Ltd.

Shaanxi Peakrise Metal Co., Ltd. is a trusted global supplier of ASTM B550 Zirconium Alloy Wire, renowned for delivering top-quality non-ferrous metal products. With over a decade of experience in international trade, we specialize in providing high-purity zirconium alloy wires that meet the rigorous standards of ASTM B550 (American Society for Testing and Materials). Our zirconium alloy wire is highly valued in industries that demand precision and durability, such as nuclear energy, aerospace, and chemical processing.

Zirconium alloy wires are known for their outstanding corrosion resistance, low thermal neutron absorption, and excellent mechanical properties, making them essential in critical applications where safety and performance cannot be compromised. Our production process adheres to strict quality control measures, ensuring that every batch of zirconium alloy wire meets the highest global standards. Whether you are looking for wire for welding, medical devices, or nuclear applications, Shaanxi Peakrise Metal Co., Ltd. is your reliable partner for all your zirconium alloy wire needs.

Product Parameters

| Property | ASTM 550 Standard Value | Tolerance |

|---|---|---|

| Diameter | 0.2 mm - 5.0 mm | ± 0.01 mm |

| Length | 100 mm - 5000 mm | ± 0.5 mm |

| Density | 6.51 g/cm³ | ± 0.02 g/cm³ |

| Melting Point | 1855°C | ± 5°C |

| Yield Strength | ≥ 230 MPa | ± 10 MPa |

| Tensile Strength | ≥ 379 MPa | ± 10 MPa |

| Chemical Composition | Percentage | ASTM Standard |

|---|---|---|

| Zirconium (Zr) | ≥ 95% | ASTM B550 |

| Hafnium (Hf) | ≤ 4.5% | ASTM B550 |

| Oxygen (O) | ≤ 0.16% | ASTM B550 |

| Nitrogen (N) | ≤ 0.025% | ASTM B550 |

| Iron (Fe) | ≤ 0.2% | ASTM B550 |

| Chromium (Cr) | ≤ 0.2% | ASTM B550 |

| Mechanical Properties | Standard Value | Test Method |

|---|---|---|

| Tensile Strength (MPa) | 379 - 400 MPa | ASTM E8 |

| Elongation (%) | 30% | ASTM E8 |

| Hardness (HV) | 120 - 160 HV | ASTM E384 |

| Modulus of Elasticity (GPa) | 68 - 76 GPa | ASTM E1876 |

| Electrical Conductivity | ≤ 0.3% IACS | ASTM B193 |

Physical and Chemical Properties

Zirconium alloy wire is characterized by its superior resistance to corrosion in harsh environments, particularly in high-temperature and chemically aggressive conditions. Its low absorption of thermal neutrons makes it ideal for use in nuclear reactors. Additionally, zirconium alloys maintain excellent ductility and strength, even at elevated temperatures.

- Corrosion Resistance: Zirconium alloys are highly resistant to corrosion, especially in acidic and alkaline environments.

- Low Thermal Neutron Absorption: This makes zirconium alloy wires suitable for nuclear applications, where neutron absorption must be minimized.

- High Melting Point: With a melting point of 1855°C, zirconium alloy wires can operate in high-temperature environments without degrading.

|

|

|

Product Functions

- Corrosion Resistance: ASTM zirconium alloy wire offers exceptional resistance to corrosion, making it an essential component in chemical processing equipment and marine applications.

- High Strength and Durability: Despite its lightweight nature, zirconium alloy wires offer high tensile strength and toughness, ensuring durability in demanding applications.

- Excellent Weldability: The wire's superior weldability allows it to be used in high-performance welding and fabrication processes, particularly in the aerospace and nuclear sectors.

- Low Neutron Absorption: Zirconium's low neutron absorption properties make it ideal for use in nuclear reactors, enhancing the efficiency and safety of reactor components.

|

|

|

|

|

|

|

|

|

|

Product Applications

- Nuclear Industry: Due to its low neutron absorption and high corrosion resistance, zirconium alloy wire is used in fuel cladding, structural components, and other critical parts in nuclear reactors.

- Aerospace: Zirconium alloy wire's strength and resistance to high temperatures make it ideal for aerospace applications, such as in jet engines and other high-performance systems.

- Chemical Processing: In the chemical industry, zirconium alloy wire is used in environments where extreme corrosion resistance is required, such as in piping systems, valves, and heat exchangers.

- Medical Devices: The biocompatibility and durability of zirconium alloys allow them to be used in medical implants and surgical instruments.

- Welding Applications: Due to its excellent weldability, zirconium alloy wire is used in precision welding applications, especially where corrosion resistance is crucial.

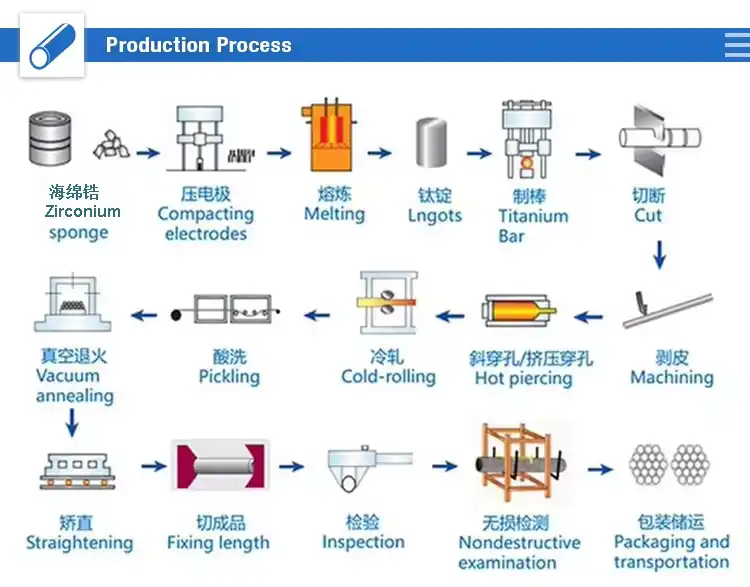

Manufacturing Process

Our zirconium alloy wire is produced using a series of precise and advanced steps to ensure top-notch quality:

- Melting: Raw materials are melted in vacuum arc furnaces to remove impurities and achieve a homogeneous alloy.

- Rolling: The ingots are hot-rolled and then cold-rolled to achieve the desired thickness and dimensions.

- Annealing: The wires undergo controlled heat treatment to enhance ductility and reduce internal stresses.

- Drawing: The wires are drawn through precision dies to obtain the final diameter with tight tolerances.

- Quality Control: Each batch undergoes rigorous testing, including chemical composition analysis, tensile testing, and microstructure evaluation.

Packaging and Logistics

- Wooden Crates: Ensures protection from external damage during transportation.

- Cardboard Boxes: Lightweight and easy to handle for smaller orders.

- Foam Padding: Provides cushioning to prevent damage from impacts.

- Waterproof Packaging: Ensures protection against moisture and humidity.

- Custom Packaging: We offer tailored packaging solutions to meet the needs of your specific order.

- Compliant with International Standards: All packaging adheres to international shipping and safety regulations.

|

|

|

|

|

|

|

|

|

|

For logistics, we offer:

- Sea Freight: Ideal for bulk orders, providing cost-effective shipping for large quantities.

- Air Freight: For urgent shipments requiring fast delivery.

- Land Transport: Efficient and reliable for regional deliveries.

- Multimodal Transport: Combining sea, air, and land transportation for flexible delivery options.

- Courier Services: For small, urgent orders, we provide reliable express shipping services.

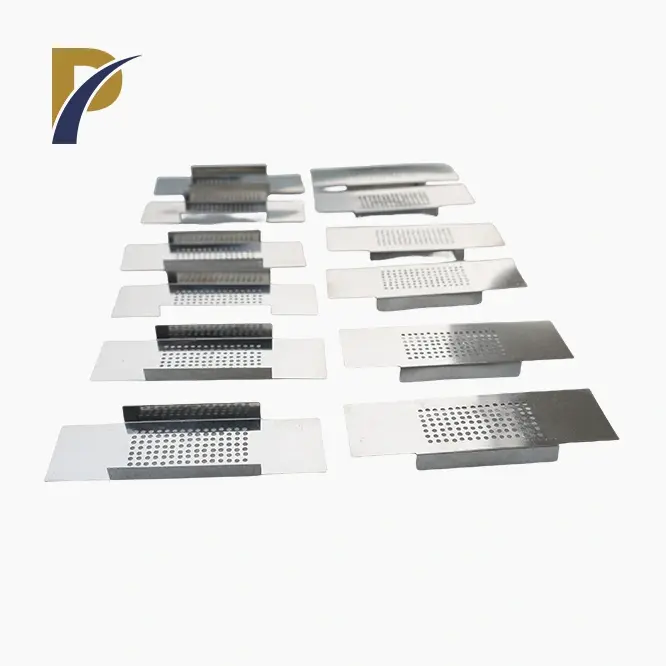

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. is proud to offer customizable OEM/ODM services. Whether you require specific dimensions, coatings, or packaging solutions, we are here to meet your unique requirements. We work closely with our clients to deliver tailor-made products that align with their precise specifications, ensuring that each project is completed to the highest standards.

|

|

|

|

|

|

|

|

|

FAQs

- What is the minimum order quantity (MOQ)?

Our standard MOQ for zirconium alloy wire is 10 kg, but we can adjust based on customer needs. - Can you produce custom wire sizes?

Yes, we provide OEM services and can manufacture zirconium alloy wire in custom diameters and lengths. - What are the delivery times?

Standard delivery is 3-4 weeks for most orders. Custom orders may require additional lead time. - Do you provide sample orders?

Yes, we offer samples for testing purposes, but shipping fees may apply. - How do you ensure product quality?

We have a strict quality control process that includes chemical analysis, mechanical testing, and visual inspections to ensure that every batch meets the highest standards.

Contact Us – Partner with Shaanxi Peakrise Metal Co., Ltd.

Are you looking for a reliable zirconium alloy wire supplier? Contact us today at info@peakrisemetal.com to discuss your requirements. We offer high-quality products, competitive pricing, and custom solutions tailored to your needs. Whether you're in the nuclear, aerospace, or medical industry, Shaanxi Peakrise Metal Co., Ltd. is here to support your business. Let's build a lasting partnership!

YOU MAY LIKE

-

VIEW MOREmolybdenum high temperature alloy tzm rod

VIEW MOREmolybdenum high temperature alloy tzm rod -

VIEW MOREmolybdenum sheet /plate for heat shield

VIEW MOREmolybdenum sheet /plate for heat shield -

VIEW MOREmolybdenum wire drawing

VIEW MOREmolybdenum wire drawing -

VIEW MOREZirconium Sheet for Heat Exchangers

VIEW MOREZirconium Sheet for Heat Exchangers -

VIEW MORE0.5mm,0.3mm,0.25mm Zr702 Zirconium Wire In Coil Zirconium Wire

VIEW MORE0.5mm,0.3mm,0.25mm Zr702 Zirconium Wire In Coil Zirconium Wire -

VIEW MOREZirconium Alloy Metal Rods

VIEW MOREZirconium Alloy Metal Rods -

VIEW MOREZirconium Alloy Sheet for Industry

VIEW MOREZirconium Alloy Sheet for Industry -

VIEW MOREu shape sic heating element Silicon Carbon rod

VIEW MOREu shape sic heating element Silicon Carbon rod