Zirconium Round Tubes for Industry

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

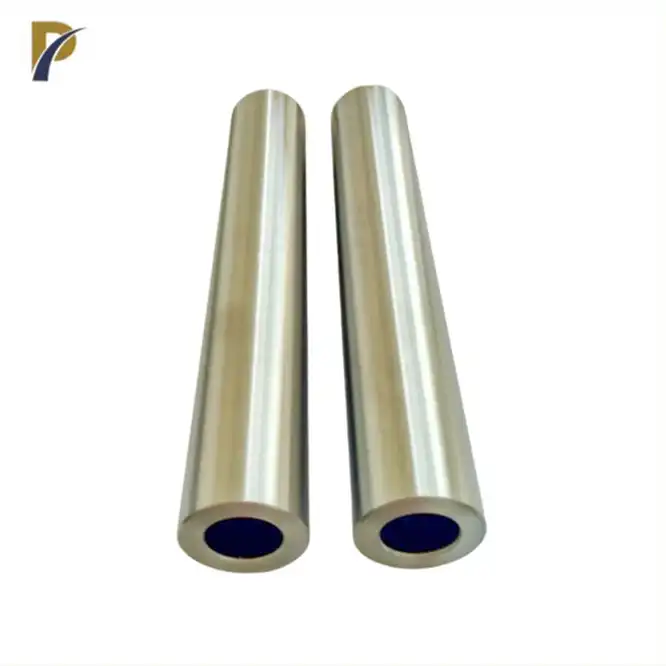

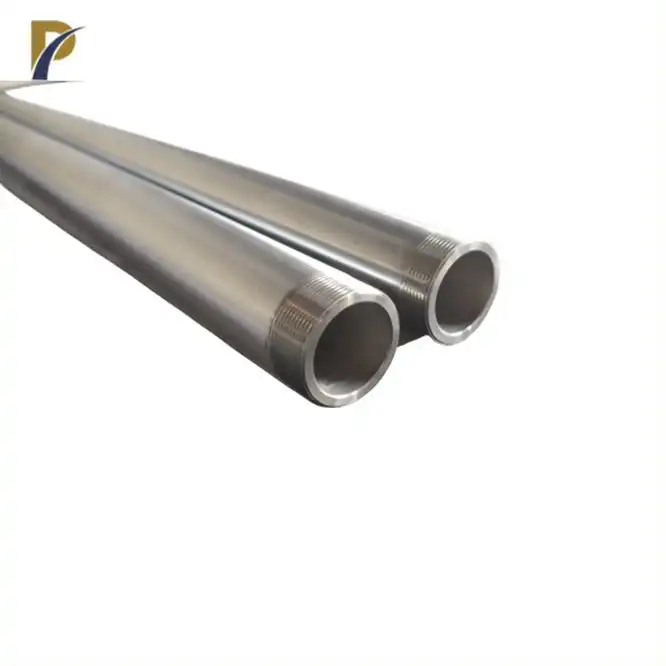

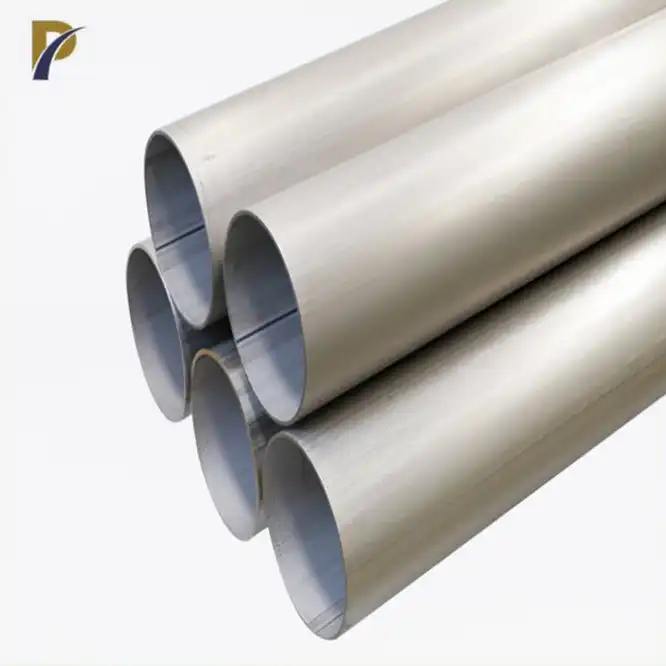

Product Introduction: Zirconium Round Tubes for Industry

Zirconium Round Tubes are essential components in many industrial applications due to their unique properties such as excellent corrosion resistance, high melting point, and remarkable strength at elevated temperatures. These characteristics make zirconium tubes ideal for use in harsh environments, including chemical processing, nuclear power plants, and aerospace industries. Zirconium (Zr), with atomic number 40, is a transition metal known for its ability to withstand corrosive substances like hydrochloric and sulfuric acid, making it a reliable material for use in environments where high resistance to corrosion is essential.

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer and global supplier of Zirconium Round Tubes for industrial use. With over a decade of experience in non-ferrous metal production and exports, we have established a strong presence in the global market by offering high-quality zirconium tubes that meet international standards. Our advanced production facilities and stringent quality control ensure that every tube we manufacture adheres to the highest standards of performance and reliability. Whether you are in need of standard sizes or customized specifications, Shaanxi Peakrise Metal Co., Ltd. is your trusted partner for industrial zirconium tube solutions.

|

|

|

Product Parameters Table

Name: Zirconium seamless pipe

Grade: Zr2 Zr4 Zr702 Zr705 Zr60804

Density: 6.51g/cm3

Diameter: 6-300mm

Wall thickness: 0.5-10mm

Length: <20meters

Or process according to customer's request.

Standard: ASTM B658,ASTM B353

Main steps of processing: Preparation of consumable electrodes, casting, forging, hot extrusion (tube blank), cold working and finishing.

| Parameter | Value |

|---|---|

| Max Operating Temperature | 800°C |

| Surface Finish | Polished, Brushed, or as required |

| Compliance | ASTM B523, AMS 4941, ASME SB523 |

| Tolerances | ±0.05 mm (Diameter), ±0.1 mm (Length) |

| Formability | Good at room and elevated temperatures |

| Welding Compatibility | Excellent (Arc, TIG, Plasma) |

| Corrosion Resistance | High (Acids, Alkalis, Seawater) |

| Oxidation Resistance | Excellent up to 450°C |

Physical and Chemical Properties

- Melting Point: Zirconium has an exceptionally high melting point of 1855°C, making it suitable for high-temperature applications.

- Corrosion Resistance: Zirconium’s resistance to both acidic and basic environments ensures long-term performance in aggressive industrial settings.

- Density: With a density of 6.52 g/cm³, zirconium is relatively lightweight, providing strength without excessive mass.

- Thermal Conductivity: It possesses moderate thermal conductivity, ensuring efficient heat dissipation in high-temperature operations.

- Non-reactive: Zirconium remains inert under extreme conditions, offering safety and reliability in industries such as nuclear power and chemical processing.

| Standard | Grade | Status | Rm(≥)/MPa | Rp0.2(≥)/MPa | A51mm(≥)/% |

| ASTM B658 Zr seamless tube/welding pipe |

R60702 R60704 R60705 |

Annealed |

379 413 552 |

207 241 379 |

16 14 16 |

Product Functions

- Corrosion Resistance: Zirconium’s superior corrosion resistance allows it to maintain structural integrity in harsh environments like chemical processing plants, oil refineries, and seawater applications.

- High Strength-to-Weight Ratio: The tubes offer excellent strength while being relatively lightweight, making them ideal for aerospace and automotive industries.

- Thermal Stability: The high melting point ensures that zirconium round tubes perform well in high-temperature applications without losing structural properties.

- Durability: With low reactivity and high resistance to oxidation, these tubes are durable, providing longevity in demanding industrial uses.

- Non-magnetic Properties: Zirconium tubes are non-magnetic, making them ideal for sensitive equipment and electronic applications.

|

|

|

Product Applications

- Chemical Processing: Zirconium round tubes are used in the construction of reactors, heat exchangers, and piping systems due to their high corrosion resistance to strong acids and alkalis.

- Nuclear Industry: Zirconium’s low absorption cross-section for thermal neutrons makes it an essential material for nuclear reactors, particularly for fuel cladding and structural components.

- Aerospace: The lightweight yet strong properties of zirconium tubes make them suitable for aerospace applications, where weight reduction and high strength are critical.

- Medical Devices: Its biocompatibility makes zirconium suitable for medical equipment, including surgical instruments and implants.

- Marine Applications: Due to its resistance to seawater corrosion, zirconium tubes are increasingly used in offshore oil and gas platforms and shipbuilding.

Production Process and Manufacturing Flow

- Material Selection: High-purity zirconium ore is sourced and refined to ensure the highest quality raw material.

- Melting: The zirconium is melted in vacuum arc furnaces to remove impurities and achieve the required material grade.

- Tube Forming: The zirconium is drawn through a series of dies to achieve the desired tube size, ensuring accurate dimensions.

- Heat Treatment: The tubes are annealed in vacuum furnaces to improve strength and ductility.

- Precision Machining: Final machining processes such as cutting, polishing, and surface treatment are applied to meet client specifications.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

- Wooden Box Packaging: Sturdy, shock-resistant wooden boxes are used to protect the zirconium tubes during long-distance shipping.

- Foam-Filled Packaging: Foam padding is used to safeguard the tubes from any mechanical damage during transit.

- Waterproof and Moisture-proof Packaging: Special waterproof materials are used to protect the tubes from humidity and water damage.

- Custom Packaging: Available upon request, ensuring that your products arrive in the best possible condition.

- Compliance: All packaging materials meet international shipping and safety standards.

|

|

|

|

|

|

|

|

|

|

Logistics

- Sea Freight: Ideal for large-volume orders with affordable costs and extensive global coverage.

- Air Freight: For urgent shipments requiring fast delivery, we offer air freight services to all major airports worldwide.

- Land Transport: Available for regions with established road and rail networks, ensuring timely deliveries.

- Multimodal Transport: Combining different logistics options to deliver your products efficiently and cost-effectively.

- Express Services: For small, time-sensitive shipments, we partner with international couriers like DHL, FedEx, and UPS.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers full OEM and ODM services for zirconium round tubes. Whether you need custom dimensions, special finishes, or unique packaging, our team is ready to work closely with you to develop products tailored to your needs. We use advanced manufacturing techniques and offer flexible production schedules to accommodate your orders, large or small.

Frequently Asked Questions (FAQs)

-

What grades of zirconium are available?

We offer grades such as Zr702, Zr705, and Zr704, depending on your application requirements. -

Can you provide custom sizes?

Yes, we offer fully customizable sizes based on your specific industrial needs. -

How long does production take?

The production timeline typically ranges from 2 to 6 weeks, depending on the order size and customization requirements. -

Do you offer global shipping?

Yes, we ship worldwide and work with leading logistics providers to ensure safe and timely delivery. -

What are the payment terms?

We offer flexible payment options, including T/T, L/C, and PayPal, depending on the order value and customer location.

Contact Us – Start Your Partnership with Shaanxi Peakrise Metal Co., Ltd.

Ready to take your industrial projects to the next level with our high-performance Zirconium Round Tubes? Contact us today at info@peakrisemetal.com to discuss your specific needs. Whether you require standard tubes or fully customized solutions, Shaanxi Peakrise Metal Co., Ltd. is here to help you succeed. Our team of experts is ready to provide you with a competitive quote and top-tier customer.