High-Grade Zirconium Metal Tube

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

High-Grade Zirconium Metal Tube – Product Overview

At Shaanxi Peakrise Metal Co., Ltd., we specialize in producing high-grade zirconium metal tubes tailored for a wide range of industrial applications. Zirconium metal is well known for its outstanding corrosion resistance, high melting point, and remarkable mechanical properties, making it an ideal material for industries requiring durability in extreme conditions. As a leading supplier of High-Grade Zirconium Metal Tubes, we pride ourselves on delivering top-quality, precision-engineered products that meet the stringent demands of our clients globally.

Our zirconium tubes are utilized in critical sectors such as nuclear power, aerospace, chemical processing, and biomedical industries, where superior corrosion resistance and thermal stability are crucial. With over a decade of experience in the non-ferrous metal industry, Shaanxi Peakrise Metal Co., Ltd. offers a range of customized zirconium tube solutions to meet specific customer needs, adhering to the highest industry standards. Our tubes are produced using state-of-the-art equipment and go through rigorous quality control procedures to ensure optimal performance and reliability.

Product Specifications

| Parameter | Standard | Value |

|---|---|---|

| Diameter | ASTM B523 | 5.0mm - 400mm |

| Wall Thickness | ASTM B523 | 0.5mm - 10mm |

| Length | Customizable | 100mm - 6000mm |

| Purity | ASTM B551 | ≥ 99.2% |

| Density | ASTM B551 | 6.49 g/cm³ |

| Melting Point | ASTM E112 | 1855°C |

| Parameter | Standard | Value |

|---|---|---|

| Tensile Strength | ASTM E8 | ≥ 380 MPa |

| Yield Strength | ASTM E8 | ≥ 200 MPa |

| Elongation | ASTM E8 | ≥ 20% |

| Hardness (Vickers) | ASTM E92 | 120 HV |

| Thermal Conductivity | ASTM E1461 | 22.5 W/m·K |

| Modulus of Elasticity | ASTM E111 | 97 GPa |

|

|

|

Physical and Chemical Properties

Zirconium metal has distinct characteristics that make it an essential material in several high-performance applications:

- Corrosion Resistance: Zirconium forms a protective oxide layer on its surface, making it highly resistant to acids, alkalis, and seawater, making it ideal for harsh chemical environments.

- High Melting Point: With a melting point of 1855°C, zirconium metal remains stable in extremely high-temperature applications.

- Low Thermal Neutron Cross Section: This property makes zirconium a key material for nuclear reactors, as it does not absorb neutrons easily.

- Biocompatibility: Zirconium is biocompatible, making it a preferred material for medical implants.

Product Functions

-

Corrosion Resistance: Zirconium tubes are commonly used in environments where corrosion by chemicals, seawater, or other corrosive substances is a concern. This is due to zirconium's ability to form a protective oxide layer, ensuring durability and a longer service life.

-

High-Temperature Resistance: Our zirconium tubes can withstand extreme temperatures, making them an ideal choice for heat exchangers and furnace components in the chemical and nuclear industries.

-

Lightweight but Strong: Zirconium’s high strength-to-weight ratio allows for lightweight yet robust components in aerospace and marine engineering.

-

Biocompatibility for Medical Use: Given zirconium’s non-toxic, non-reactive nature, it is often used for medical implants and surgical instruments, where biocompatibility is essential.

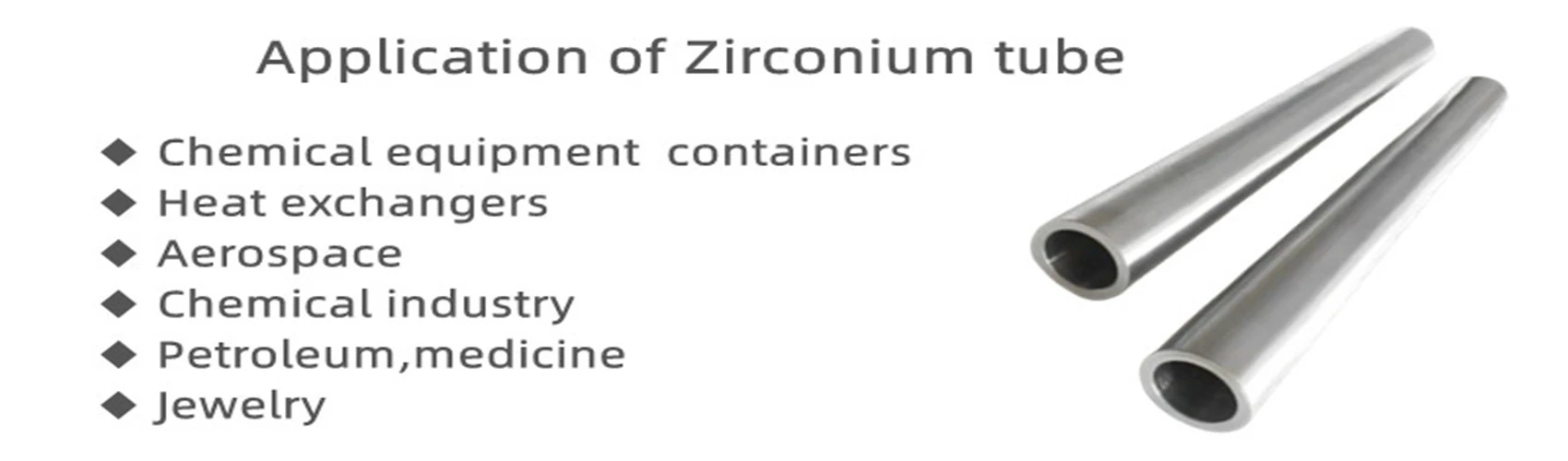

Applications of Zirconium Metal Tubes

-

Nuclear Reactors: Zirconium tubes are indispensable in nuclear reactor cores due to their low neutron absorption and resistance to radiation damage.

-

Chemical Processing: Zirconium’s corrosion resistance makes it suitable for piping and heat exchangers in industries dealing with aggressive chemicals, ensuring equipment longevity and safety.

-

Aerospace: The aerospace industry benefits from zirconium’s strength and resistance to high temperatures, using it in engines and structural components where lightweight durability is crucial.

-

Medical Implants: Biocompatible and resistant to body fluids, zirconium tubes are used in medical implants, orthopedic devices, and dental applications.

-

Marine Engineering: Zirconium’s resistance to seawater corrosion makes it a valuable material for applications in marine environments, such as shipbuilding and offshore equipment.

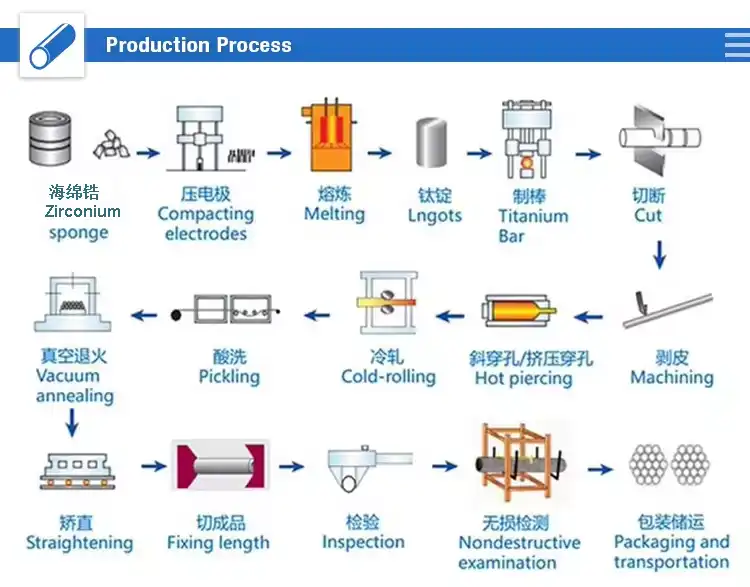

Production Process

At Shaanxi Peakrise Metal Co., Ltd., we follow a precise and thorough manufacturing process to produce high-grade zirconium metal tubes:

-

Raw Material Selection: We source zirconium from trusted suppliers, ensuring high purity and quality.

-

Vacuum Arc Melting: The raw zirconium is melted in a vacuum to eliminate impurities, producing a highly pure ingot.

-

Rolling and Extrusion: The zirconium ingot is then rolled and extruded into tubes of the desired size and shape.

-

Heat Treatment: The tubes undergo annealing in a vacuum furnace to improve their mechanical properties and ensure uniform grain structure.

-

Quality Inspection: All products are rigorously inspected to meet ASTM standards, including testing for mechanical strength, corrosion resistance, and dimensional accuracy.

Why Choose Us?

-

Over a Decade of Experience: We have over ten years of expertise in the non-ferrous metal industry, ensuring the highest level of product quality and service.

-

Advanced Production Equipment: Our factory is equipped with state-of-the-art machinery, including vacuum arc melting furnaces and CNC machines, ensuring precision and consistency.

-

Comprehensive Quality Control: All products are manufactured in compliance with ASTM standards and ISO 9001 certified, guaranteeing top-tier quality and reliability.

-

Global Reach: Our products are exported to countries worldwide, including the United States, Germany, South Korea, and Australia, with established long-term relationships with our clients.

-

Custom Solutions: We offer OEM and ODM services to meet your specific project requirements.

Packaging & Logistics

-

Packaging Options:

- Wooden Crate Packaging – for secure transport.

- Carton Packaging – suitable for smaller quantities.

- Foam Cushioning Packaging – to prevent damage during transit.

- Waterproof and Moisture-proof Packaging – ensures product integrity in humid conditions.

- Custom Packaging – available upon request to meet specific needs.

-

Logistics:

- Sea Freight – for bulk orders with a longer delivery timeline.

- Air Freight – for urgent deliveries or lighter shipments.

- Land Freight – for deliveries within nearby regions.

- Multimodal Transport – combining multiple shipping methods for efficient delivery.

- Express Services – for small orders requiring expedited shipping.

|

|

|

|

|

|

|

|

|

|

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer complete OEM/ODM services to meet the specific needs of our clients. Whether you require custom sizes, finishes, or special requirements, our team of engineers and metallurgists can tailor our zirconium metal tubes to your exact specifications. We work closely with our clients from design through to production, ensuring a seamless and efficient process.

|

|

|

|

|

|

|

|

|

|

Frequently Asked Questions (FAQ)

-

What is the purity of your zirconium metal tubes?

Our zirconium metal tubes have a purity of 99.2% or higher, adhering to ASTM B551 standards. -

Do you offer customized dimensions for zirconium tubes?

Yes, we provide custom sizes and thicknesses based on your specific requirements. -

What industries are zirconium tubes commonly used in?

Zirconium tubes are widely used in the nuclear, aerospace, chemical, marine, and medical industries due to their unique properties. -

What is your lead time for orders?

Lead times vary depending on the order size and customization but typically range from 4 to 6 weeks. -

Can you provide certification for the materials used?

Yes, we provide full material certification, including ASTM standards compliance and chemical composition reports.

Call to Action (CTA) – Contact Us Today!

If you're looking for high-quality zirconium metal tubes for your next project, look no further than Shaanxi Peakrise Metal Co., Ltd.. With our extensive experience, advanced production capabilities, and commitment to quality, we are the ideal partner for your metal needs.

Contact us today at info@peakrisemetal.com to discuss your requirements, and let us provide you with the best solutions in the industry!

YOU MAY LIKE

-

VIEW MOREZirconium Sheet for Chemical Use

VIEW MOREZirconium Sheet for Chemical Use -

VIEW MOREZirconium Welding Wire

VIEW MOREZirconium Welding Wire -

VIEW MORE0.5mm,0.3mm,0.25mm Zr702 Zirconium Wire In Coil Zirconium Wire

VIEW MORE0.5mm,0.3mm,0.25mm Zr702 Zirconium Wire In Coil Zirconium Wire -

VIEW MOREUltra-Thin Zirconium Metal Foil

VIEW MOREUltra-Thin Zirconium Metal Foil -

VIEW MORECorrosion-Resistant Zirconium Tubes

VIEW MORECorrosion-Resistant Zirconium Tubes -

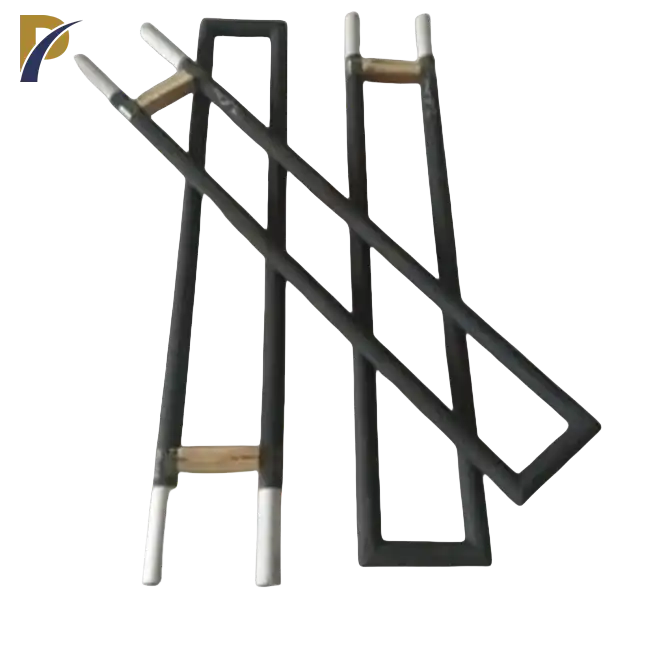

VIEW MOREGDU u shape sic heating elements

VIEW MOREGDU u shape sic heating elements -

VIEW MOREZirconium Chemical Industry Rod UNS R60702 Zr702 ZR2

VIEW MOREZirconium Chemical Industry Rod UNS R60702 Zr702 ZR2 -

VIEW MOREmetal technology zirconium crucible with flange rims

VIEW MOREmetal technology zirconium crucible with flange rims