Zirconium Welding Wire

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

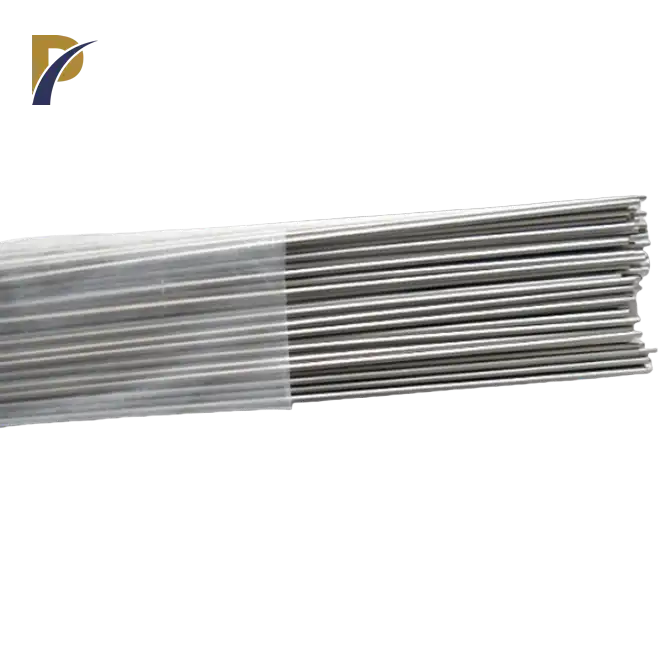

Zirconium Welding Wire

Product Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your premier supplier of Zirconium Welding Wire. With over a decade of experience in the production of non-ferrous metals, we specialize in providing high-quality zirconium products that meet international standards. Zirconium welding wire is crucial for industries that require excellent corrosion resistance and high-temperature performance, making it an essential choice for critical applications such as aerospace, nuclear power, and chemical processing.

Our Zirconium Welding Wire is manufactured using advanced techniques and state-of-the-art equipment, ensuring superior quality and reliability. Zirconium's unique properties, such as its ability to withstand extreme temperatures and resist aggressive environments, make our welding wire ideal for projects demanding high performance. Whether you are involved in the fabrication of reactors or heat exchangers, our zirconium wire provides the strength and durability required for the most demanding tasks.

At Shaanxi Peakrise Metal Co., Ltd., we understand the importance of trust and quality in your supply chain. Our commitment to excellence drives us to continuously improve our products and services, ensuring that we meet the diverse needs of our global clientele. Join us as we help you achieve your project goals with our exceptional Zirconium Welding Wire.

Product Specifications

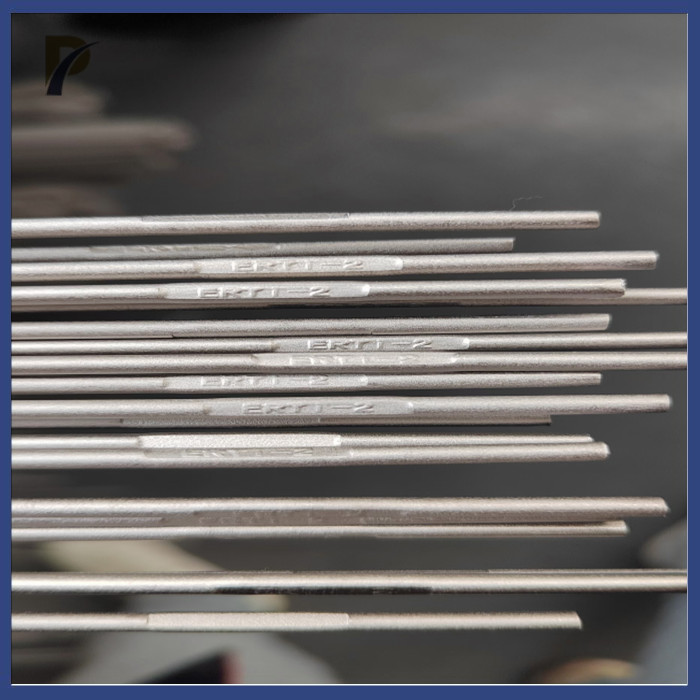

| Name | Zirconium welding wire |  |

| Grade | ERZr-2 Zr60702,ERZr-4 Zr60705 | |

| Diameter | φ1.0 φ1.6 φ2.4 φ2.0 φ3.2 φ4.0 | |

| Density | 6.51g/cm3 | |

| Purity | >99.0% | |

| Surface | pickling surface | |

| Standard | AWS. A5.24 |

| Diameter | mm | 1.2 | 1.6 | 2.0 | 2.4 | 3.2 | 4.0 |

| Electric current | A | 65-90 | 90-110 | 100-110 | 110-140 | 140-180 | 180-230 |

Physical and Chemical Properties

Zirconium is a transition metal known for its exceptional properties, including high resistance to corrosion and oxidation. It has a unique ability to form a protective oxide layer, which significantly enhances its durability in harsh environments. Additionally, zirconium is non-toxic and biocompatible, making it suitable for applications in the medical field.

-

Corrosion Resistance: Zirconium exhibits outstanding resistance to corrosive environments, particularly in acidic and alkaline solutions. This property makes it an ideal choice for chemical processing and nuclear applications.

-

High-Temperature Stability: Zirconium maintains its mechanical properties at elevated temperatures, allowing for its use in high-temperature welding applications without compromising integrity.

-

Biocompatibility: With non-toxic characteristics, zirconium is safe for use in medical applications, including surgical implants and devices.

Zr702 Chemical:

| Content | Zr+Hf | Hf | Fe+Cr | O | H | N | C | Each impurity | Total impurity |

| Standard value | ≥99.0 | ≤4.5 | ≤0.2 | 0.11-0.15 | ≤0.05 | ≤0.015 | ≤0.03 | ≤0.05 | ≤0.2 |

| Typical value | 99.3 | 1.91 | 0.04 | 0.12 | 0.004 | 0.005 | 0.006 | - | 0.002 |

Zr705 Chemical:

| Content | Zr+Hf | Hf | Fe+Cr | Nb | O | H | N | C | Each impurity | Total impurity |

| Standard value | ≥95.5 | ≤4.5 | 0.2 | 2.0-3.0 | 0.11-0.16 | ≤0.05 | ≤0.015 | ≤0.03 | ≤0.05 | ≤0.2 |

| Typical value | 97.6 | 0.91 | 0.18 | 2.2 | 0.12 | 0.002 | 0.004 | 0.013 | 0.02 | 0.002 |

Product Features

-

Exceptional Corrosion Resistance: The primary function of our Zirconium Welding Wire is its ability to withstand corrosion in aggressive environments, ensuring long-lasting performance.

-

High Strength-to-Weight Ratio: Our welding wire provides excellent tensile strength while maintaining a lightweight profile, making it easy to handle and apply.

-

Versatile Applications: The wire is designed for various applications, including aerospace, nuclear, and chemical industries, offering flexibility for multiple projects.

-

Easy Weldability: Our zirconium wire can be easily welded using conventional techniques, enabling efficient manufacturing processes.

-

Customizable Lengths and Diameters: We offer various sizes to meet specific project requirements, ensuring that you receive exactly what you need.

Product Applications

The versatility of Zirconium Welding Wire makes it suitable for a wide range of applications:

-

Aerospace Industry: Used in the construction of aircraft components and structures that require high strength and lightweight materials.

-

Nuclear Power Plants: Essential for the fabrication of reactor components due to its corrosion resistance and ability to withstand high radiation environments.

-

Chemical Processing: Ideal for manufacturing pipes, valves, and other equipment exposed to aggressive chemicals, ensuring safe and efficient operations.

-

Biomedical Applications: Due to its biocompatibility, zirconium is used in medical devices and implants, providing a safe solution for patient care.

As industries continue to evolve, the demand for high-performance materials like zirconium welding wire is expected to grow, driven by advancements in technology and an increasing focus on sustainability.

|

|

Manufacturing Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we employ a rigorous manufacturing process to produce high-quality Zirconium Welding Wire:

-

Raw Material Sourcing: We source premium zirconium metal, ensuring high purity levels for optimal performance.

-

Melting and Casting: Using vacuum arc melting and other advanced techniques, we melt the zirconium and cast it into suitable forms for wire production.

-

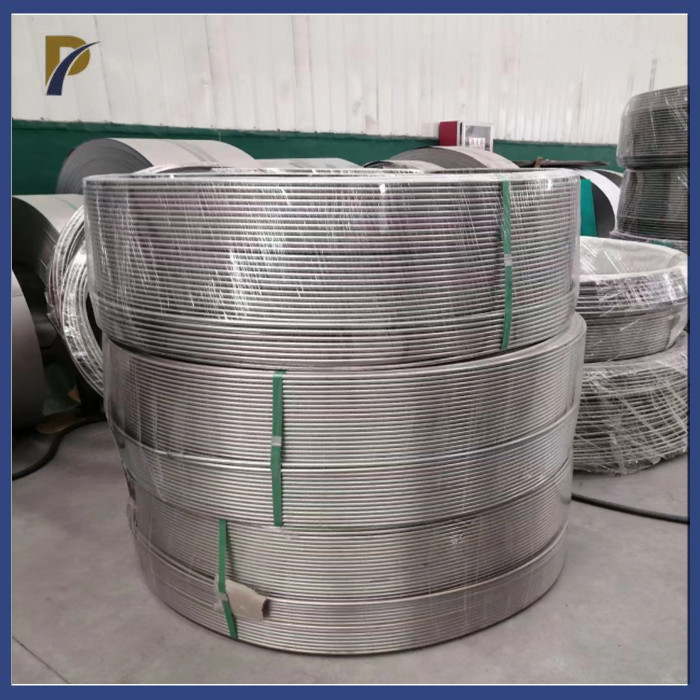

Wire Drawing: The cast forms are drawn into wires of various diameters using precision wire drawing machines.

-

Surface Treatment: Each wire undergoes a cleaning process to remove any impurities or oxides, ensuring superior quality.

-

Quality Control: Our dedicated quality control team conducts thorough testing of mechanical and chemical properties to ensure compliance with industry standards.

-

Packaging: Finally, the finished wires are carefully packaged to maintain their quality during transportation.

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is a well-established enterprise specializing in the production of non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Our extensive product range includes over 100 different types of high-performance materials.

Since entering the foreign trade market in 2010, we have successfully exported our products to various countries, including the United States, Germany, South Korea, and Australia. Our commitment to quality has earned us a reputation as a trusted supplier in the global market.

We pride ourselves on our advanced production facilities, which include vacuum arc melting furnaces, laser cutters, plasma welding equipment, and a range of CNC machines. Our skilled team of professionals is dedicated to providing high-quality products and services, ensuring complete customer satisfaction.

|

|

|

Logistics and Packaging

We prioritize the safe and efficient delivery of our products:

Packaging Options

- Wooden Crate Packaging: For maximum protection during transportation.

- Carton Packaging: Lightweight and cost-effective for smaller orders.

- Foam-Filled Packaging: To absorb shocks and prevent damage.

- Waterproof and Moisture-Proof Packaging: Ensuring product integrity during transit.

- Custom Packaging: Tailored solutions to meet specific customer requirements.

- International Standard Packaging: Compliance with global shipping regulations.

Logistics Options

- Sea Freight: Cost-effective for large shipments.

- Air Freight: Fast delivery for urgent orders.

- Land Transportation: Reliable service for regional deliveries.

- Multimodal Transport: Combining different modes for efficiency.

- Courier Services: Quick delivery for smaller packages.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Experienced Manufacturer: With years of expertise in non-ferrous metal production, we have developed a reputation for quality and reliability.

- Comprehensive Product Range: We offer a diverse array of products to meet various industrial needs.

- Quality Assurance: Our rigorous quality control measures ensure that every product meets the highest standards.

- Customer-Centric Approach: We prioritize customer satisfaction, providing personalized service and support.

- Global Reach: Our extensive export experience allows us to serve customers worldwide.

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer tailored OEM/ODM services to meet the specific requirements of our clients. Whether you need custom dimensions, specialized coatings, or unique packaging solutions, our team is here to assist you. We collaborate closely with our customers to ensure that every product meets their exact specifications, providing a seamless experience from production to delivery.

-

What is the minimum order quantity for Zirconium Welding Wire?

- The minimum order quantity varies depending on the specifications. Please contact us for details.

-

Can you provide a certificate of analysis?

- Yes, we provide a certificate of analysis for each batch, confirming its compliance with industry standards.

-

How long does delivery take?

- Delivery times depend on the shipping method and destination. Typically, sea freight takes 20-30 days, while air freight takes 5-10 days.

-

Do you offer samples?

- Yes, we can provide samples upon request. Please reach out to our sales team for more information.

-

What payment methods do you accept?

- We accept various payment methods, including T/T, L/C, and PayPal.

Call to Action (CTA)

At Shaanxi Peakrise Metal Co., Ltd., we are committed to providing you with the highest quality Zirconium Welding Wire. If you are ready to elevate your projects with our superior products, contact us today at info@peakrisemetal.com. Our team is here to assist you with any inquiries and ensure you find the right solution for your needs. Let’s work together to achieve excellence in your industry!