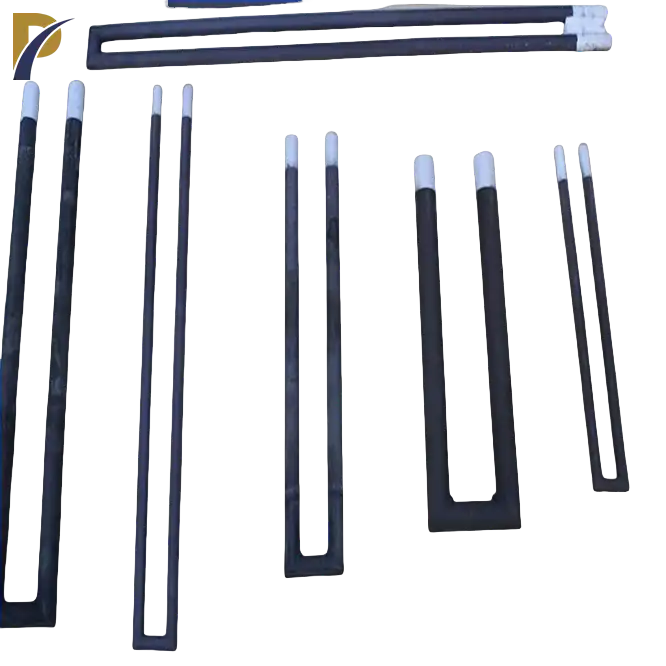

GDU u shape sic heating elements

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

U-Shape SiC Heating Elements Product Introduction Page for Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

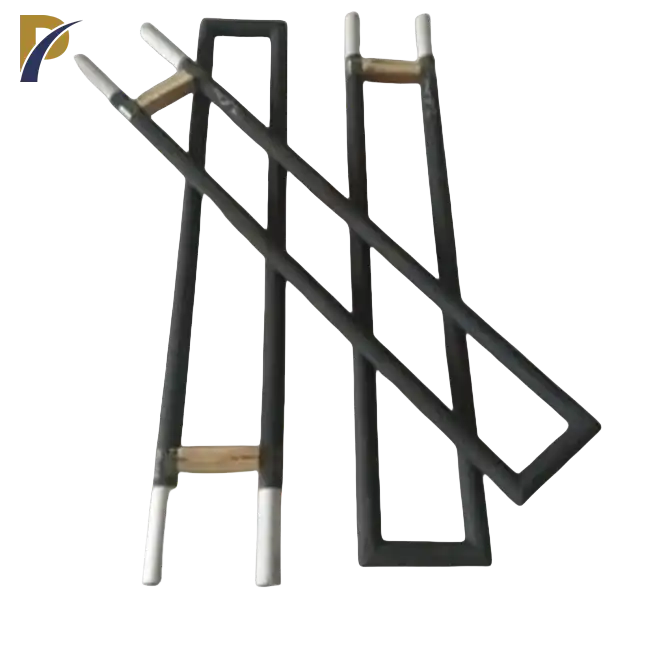

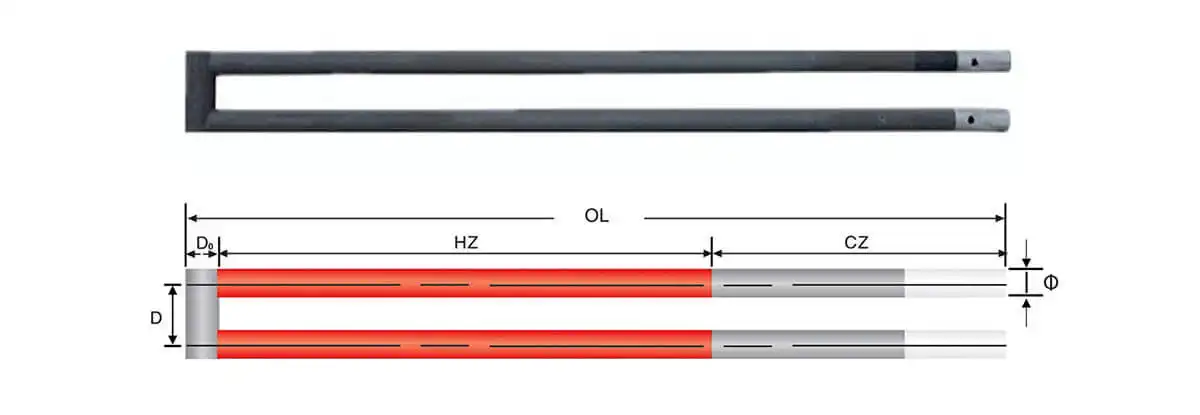

The basic characteristics of GDU silicon carbon rod: U-shaped silicon carbon rod is composed of two silicon carbon rods with equal radius and a common cold end. The U-shaped silicon carbon rod can be connected to the power line at one end of the kiln. The surface temperature of the heating part is 1500℃. It is mainly used in high-temperature furnaces and kilns with high requirements for furnace temperature uniformity. Its characteristics are power saving and long furnace life., Shaanxi Peakrise Metal Co., Ltd. takes pride in offering high-quality U-shape SiC heating elements designed to meet various industrial demands. These elements are widely used in industries like metallurgy, glass manufacturing, and ceramics due to their robust thermal conductivity and high-temperature resistance. Our U-shape SiC heating elements are specifically engineered to provide consistent performance in extreme environments, making them a preferred choice for clients worldwide.

With years of experience in non-ferrous metal production, Shaanxi Peakrise Metal Co., Ltd. has established a solid reputation as a leading supplier of U-shape SiC heating elements. We focus on providing our customers with superior products backed by meticulous quality control and unparalleled customer service.

|

|

Product Parameters

| Hot zone diameter (mm) | Hot zone length (mm) HZ1 | Cold zone length (mm) HZ2 | Center distance A(mm) | Bridge size | Resistance Range | |

| D (mm) | Length L3 | |||||

| 14 | 200 | 250 | 40 | 14 | 54 | 2.4-4.6 |

| 14 | 250 | 300 | 50 | 14 | 64 | 3.0-6.0 |

| 14 | 300 | 350 | 60 | 14 | 74 | 3.6-7.0 |

| 16 | 200 | 250 | 40 | 16 | 56 | 1.4-2.8 |

| 16 | 250 | 300 | 50 | 16 | 66 | 1.8-3.6 |

| 16 | 300 | 350 | 60 | 16 | 76 | 2.0-5.0 |

| 18 | 300 | 350 | 60 | 18 | 78 | 2.0-5.0 |

| 18 | 400 | 400 | 70 | 18 | 88 | 2.8-5.8 |

| 18 | 500 | 450 | 75 | 18 | 93 | 3.6-7.2 |

| 20 | 250 | 300 | 50 | 20 | 70 | 1.8-3.6 |

| 20 | 300 | 350 | 60 | 20 | 80 | 2.0-5.0 |

| 20 | 400 | 400 | 70 | 20 | 90 | 2.8-5.8 |

| 25 | 400 | 400 | 70 | 25 | 95 | 1.6-3.4 |

| 25 | 500 | 450 | 75 | 25 | 100 | 2.2-4.4 |

| 25 | 600 | 500 | 80 | 25 | 105 | 2.6-5.2 |

| 30 | 600 | 400 | 70 | 30 | 100 | 1.4-2.8 |

| 30 | 700 | 450 | 75 | 30 | 105 | 1.6-3.2 |

| 30 | 800 | 500 | 80 | 30 | 110 | 1.8-3.6 |

Below is a detailed product parameter table for U-shape SiC heating elements, designed to meet industry-specific requirements.

Physical and Mechanical Properties

The U-shape SiC heating elements feature exceptional thermal and mechanical properties that make them ideal for high-temperature applications. The physical properties include:

- High-Temperature Resistance: The elements can withstand temperatures up to 1600°C, making them suitable for demanding industrial applications.

- Good Thermal Conductivity: Silicon carbide is known for its excellent heat distribution, which ensures efficient heating across the surface of the element.

- High Flexural Strength: The mechanical strength of these elements allows them to resist deformation or breakage during operation.

Product Functions

U-shape SiC heating elements provide several crucial functions in industrial heating systems:

- Efficient Heat Transfer: The high thermal conductivity of SiC ensures rapid and even heat distribution, leading to efficient energy use.

- Durability in Extreme Environments: These elements are built to endure harsh operating conditions, including thermal shock and chemical exposure, prolonging service life.

- Resistance to Oxidation: The elements maintain performance over time due to the protective SiO₂ layer that forms on the surface, preventing oxidation.

- Energy Saving: The advanced design of the cold ends minimizes power loss, reducing operational costs and energy consumption.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

U-shape SiC heating elements are versatile and can be applied across multiple industries. Key applications include:

- Metallurgy: Used for heat treatment processes like annealing, sintering, and forging, providing stable heat at high temperatures.

- Glass Manufacturing: Ideal for heating glass melting furnaces where precise temperature control is critical.

- Ceramics Industry: Widely used in kilns for firing ceramics due to their ability to maintain consistent high temperatures.

- Semiconductor Industry: Essential in the production of silicon wafers, offering precise heat control and reduced contamination.

- Chemical Processing: Used in reactors and processing units that require corrosion resistance and high temperatures.

The future trend of U-shape SiC heating elements points toward energy-efficient models with longer lifespans and higher performance under extreme conditions.

|

|

Product Process and Production Flow:

The production process of U-shape SiC heating elements at Shaanxi Peakrise Metal Co., Ltd. involves multiple advanced manufacturing steps to ensure high quality:

- Material Selection: Only high-purity silicon carbide is used, ensuring the performance and longevity of the elements.

- Cold Isostatic Pressing: The SiC material is compacted under high pressure to form a uniform and dense structure.

- Sintering: The green body undergoes high-temperature sintering in an intermediate frequency furnace to strengthen the SiC structure.

- Shaping and Machining: The elements are cut and shaped using laser cutting and plasma welding to achieve precise dimensions.

- Surface Treatment: Final surface treatment ensures a protective layer that enhances resistance to oxidation and wear.

- Quality Inspection: Every element is rigorously tested for electrical resistance, thermal conductivity, and structural integrity before shipment.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts state-of-the-art manufacturing facilities, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, and plasma electron beam melting furnaces. Our comprehensive facility allows for large-scale production with strict quality controls. We are committed to maintaining ISO 9001 standards and ensuring that every product meets our customers' specifications.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Case Packaging: For heavy-duty transportation, our elements are securely packed in wooden cases.

- Carton Packaging: Smaller orders are packed in sturdy cartons, ensuring protection during transit.

- Foam-Filled Packaging: Foam padding is used to protect delicate components.

- Waterproof and Moisture-Proof Packaging: We provide waterproof packaging to protect the products from environmental damage during shipping.

- Custom Packaging: Tailored packaging solutions are available to meet specific customer requirements.

|

|

Why Choose Us?

- Rich Experience: With over a decade of experience, we are a leading manufacturer in the non-ferrous metal industry, specializing in SiC heating elements.

- Advanced Equipment: Our facility is equipped with the latest technology to ensure high precision and quality.

- Global Export: We have successfully exported our products to the United States, Germany, Australia, and several other countries, establishing long-term relationships with international clients.

- Strict Quality Control: We follow stringent quality control processes to ensure each product meets global standards.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers customized OEM and ODM services for U-shape SiC heating elements. We work closely with clients to tailor products to specific industrial needs, ensuring that our heating elements meet unique operational demands. Whether it's custom dimensions, voltage requirements, or other specifications, we provide full support throughout the design and production process.

|

|

|

|

|

|

|

|

|

|

FAQ

-

What is the typical lifespan of U-shape SiC heating elements?

- The average lifespan is 3-5 years, depending on operating conditions and maintenance practices.

-

Can these elements be customized to specific dimensions?

- Yes, we offer complete customization options, including length, diameter, and electrical specifications.

-

What industries use U-shape SiC heating elements?

- These elements are used in metallurgy, glass manufacturing, ceramics, and semiconductor production.

-

Do you provide technical support?

- Yes, we offer full technical support to assist with installation, maintenance, and troubleshooting.

-

What packaging options are available?

- We provide wooden cases, carton packaging, foam filling, and custom packaging solutions.

Contact Us

We invite global purchasers to collaborate with Shaanxi Peakrise Metal Co., Ltd. for high-quality U-shape SiC heating elements. For inquiries and orders, feel free to contact us at info@peakrisemetal.com. We look forward to establishing a long-term business partnership with you.

This content aims to attract, engage, and convert global customers through professional and well-structured information.