Zirconium Fuel Cladding Rods

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Fuel Cladding Rods Product Page for Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

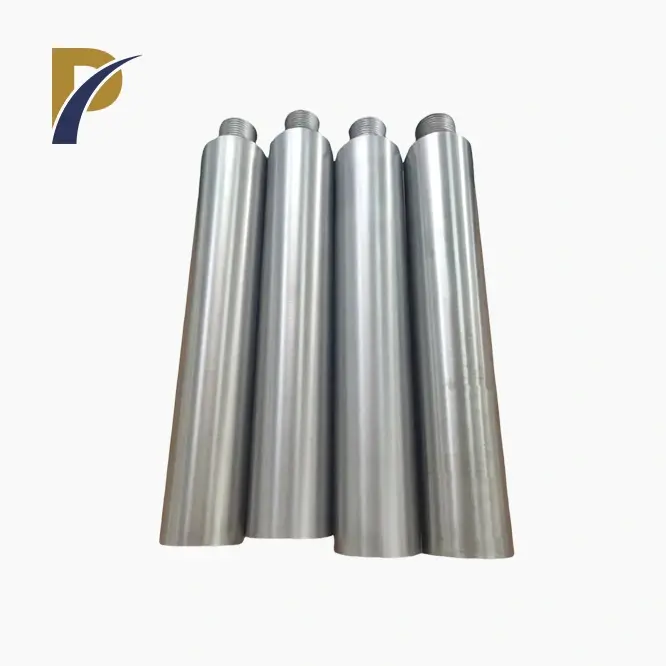

Zirconium Fuel Cladding Rods are a critical component in the nuclear industry, providing an essential barrier that protects the nuclear fuel and prevents the release of radioactive materials. Known for their exceptional corrosion resistance, high melting point, and low neutron absorption cross-section, zirconium alloys have become the preferred material for nuclear fuel cladding in light water reactors (LWRs) worldwide.

At Shaanxi Peakrise Metal Co., Ltd., we specialize in manufacturing and supplying high-quality zirconium fuel cladding rods tailored to meet the exacting demands of the nuclear energy sector. With extensive experience in producing non-ferrous metals, including zirconium, tungsten, molybdenum, and titanium alloys, we are committed to delivering premium materials that guarantee safety, performance, and durability in critical applications. Over the years, we have built a strong reputation for supplying reliable zirconium cladding rods to clients globally, meeting stringent industry standards and client-specific requirements.

Our zirconium fuel cladding rods are engineered using state-of-the-art manufacturing processes, ensuring the highest levels of precision, consistency, and quality. These rods are suitable for use in various nuclear reactor designs, offering superior thermal and mechanical performance that ensures the safe operation of nuclear reactors.

Product Specifications

| Product Name | Zirconium Fuel Cladding Rods |  |

| Grade | Zr702, Zr60001 | |

| Common size | φ21mm,φ22mm,φ23mm,φ24mm,φ25mm,φ26mm,φ27mm or according to customer's request. | |

| Length | 150mm,500mm,900mm,1000mm or as per customer request. | |

| Standard | ASTM B550 | |

| Purity | >99.7% | |

| Surface | Polished | |

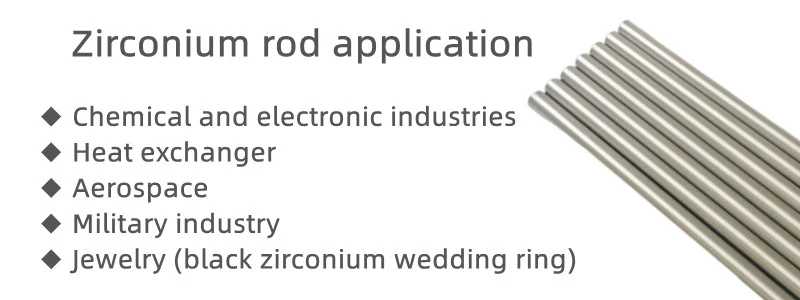

| Application | Industry , Jewelry industry |

Physical and Chemical Properties

Zirconium is renowned for its unique physical and chemical properties that make it an ideal choice for nuclear applications:

- Density: 6.52 g/cm³

- Melting Point: 1,855°C

- Thermal Conductivity: 22 W/m·K

- Coefficient of Thermal Expansion: 5.8 × 10⁻⁶/°C

- Corrosion Resistance: Excellent in most aqueous environments, particularly in high-temperature and high-pressure conditions

These properties, combined with low neutron absorption, make zirconium cladding a critical element for enhancing nuclear reactor efficiency and safety.

Product Functions

- Corrosion Resistance: Zirconium cladding rods protect the nuclear fuel from corrosive environments inside reactors, significantly extending fuel life.

- Thermal Conductivity: The high thermal conductivity of zirconium allows efficient heat transfer, optimizing reactor performance while maintaining fuel integrity.

- Low Neutron Absorption: Zirconium has a low neutron capture cross-section, making it ideal for use in reactors as it minimizes interference with the nuclear chain reaction.

- Mechanical Strength: Our zirconium cladding rods offer outstanding mechanical strength, ensuring structural integrity even under extreme reactor conditions.

- Safety Barrier: Acts as a critical safety barrier between the nuclear fuel and the coolant, preventing the release of fission products into the environment.

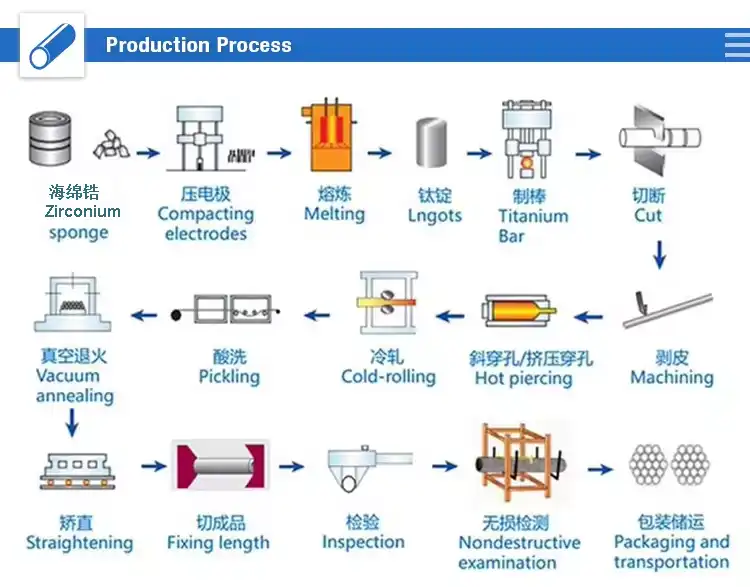

Manufacturing Process

At Shaanxi Peakrise Metal Co., Ltd., our production process for zirconium fuel cladding rods includes multiple stages of precision engineering and rigorous quality control:

- Raw Material Selection: High-purity zirconium alloys are carefully selected to meet nuclear-grade standards.

- Melting and Casting: The alloys are melted in a vacuum arc furnace to eliminate impurities and ensure homogeneity.

- Forming: The melted alloy is rolled and drawn into tubes with high dimensional accuracy.

- Heat Treatment: The tubes undergo annealing in a vacuum furnace to achieve the desired mechanical properties.

- Quality Control: Each batch is subjected to stringent non-destructive testing, including ultrasonic testing, to detect any imperfections.

- Final Inspection: Dimensional and mechanical properties are verified before shipment to ensure compliance with industry standards.

Why Choose Us?

- Rich Experience: With over a decade of experience in producing non-ferrous metals, Shaanxi Peakrise Metal Co., Ltd. is a trusted partner for high-quality zirconium products.

- Advanced Manufacturing: We utilize cutting-edge equipment such as vacuum arc melting furnaces, plasma electron beam melting, and CNC machines to deliver products of unmatched quality.

- Global Reach: Our products are exported to countries including the United States, South Korea, Germany, and more, reflecting our global commitment to excellence.

- Customized Solutions: We offer tailored manufacturing solutions to meet specific client requirements, including custom dimensions and alloy compositions.

- Rigorous Quality Assurance: Every product undergoes comprehensive testing, ensuring that our clients receive only the highest-quality zirconium fuel cladding rods.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. is proud to offer comprehensive OEM/ODM services. Whether you need customized sizes, alloy compositions, or packaging solutions, we have the expertise and flexibility to meet your needs. Our in-house team of engineers works closely with clients to ensure that every product meets exact specifications.

Packaging and Logistics

-

Packaging:

- Wooden crates for secure transportation

- Carton boxes with foam inserts for added protection

- Waterproof and moisture-resistant materials

- Custom packaging solutions available to meet client requirements

-

Logistics:

- Sea Freight: Cost-effective solution for large shipments

- Air Freight: Ideal for urgent deliveries

- Land Transportation: Reliable for regional shipments

- Multimodal Transport: Combining multiple transportation methods for efficiency

- Express Shipping: Available for small or time-sensitive orders

Frequently Asked Questions (FAQs)

-

What are the main advantages of zirconium fuel cladding rods? Zirconium fuel cladding rods offer superior corrosion resistance, high-temperature performance, and low neutron absorption, making them ideal for nuclear reactors.

-

Can you provide custom dimensions? Yes, we offer customizable lengths and diameters to meet your specific project requirements.

-

What industries use zirconium fuel cladding rods? Our zirconium rods are primarily used in nuclear reactors, but they also have applications in research facilities and advanced nuclear technology development.

-

Do you offer OEM services? Yes, we provide full OEM services, including custom alloy compositions, sizes, and packaging.

-

What quality control measures do you have in place? All products undergo rigorous testing, including non-destructive testing and dimensional checks, to ensure they meet international standards.

Call to Action (CTA) – Contact Us

Looking for a reliable supplier of zirconium fuel cladding rods? Shaanxi Peakrise Metal Co., Ltd. is your trusted partner for premium non-ferrous metal solutions. Contact us today to learn more about our products and services. Our team of experts is ready to assist with your project requirements and provide tailored solutions to meet your needs. Reach us at info@peakrisemetal.com and start your journey to high-quality zirconium fuel cladding rods. We look forward to working with you!

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes for glass furnace

VIEW MOREmolybdenum electrodes for glass furnace -

VIEW MORE50 diameter molybdenum elecrtode

VIEW MORE50 diameter molybdenum elecrtode -

VIEW MOREmolybdenum sintering boats

VIEW MOREmolybdenum sintering boats -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREtungsten nickel copper alloy

VIEW MOREtungsten nickel copper alloy -

VIEW MOREtungsten crucibles

VIEW MOREtungsten crucibles -

VIEW MOREHigh-Strength Zirconium Rods

VIEW MOREHigh-Strength Zirconium Rods -

_1741595665703.webp) VIEW MOREHeat-Resistant Zirconium Rod

VIEW MOREHeat-Resistant Zirconium Rod

_1742177699488.webp)

_1742177699518.webp)

_1742177699498.webp)

_1742177699519.webp)