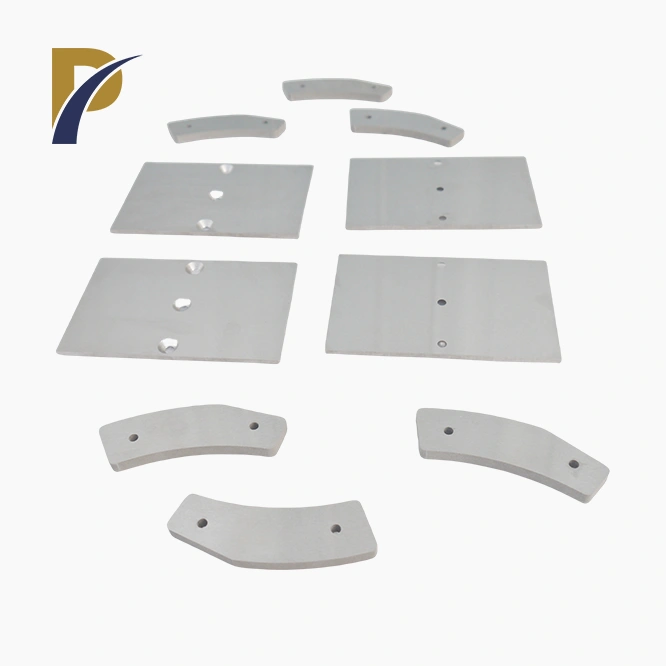

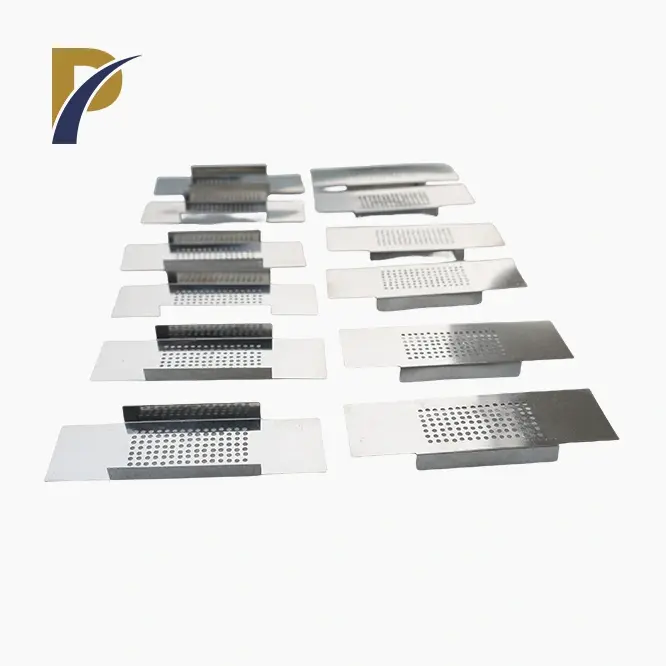

Zirconium CNC Machined Components

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium CNC Machined Components: Precision, Performance, and Reliability

Shaanxi Peakrise Metal Co., Ltd. is a trusted global supplier of high-quality Zirconium CNC Machined Components, offering precision-engineered products tailored to meet the stringent demands of various industries. With a decade of experience in non-ferrous metal production, we specialize in delivering machined components that exhibit exceptional corrosion resistance, strength, and durability. Our CNC machining capabilities ensure that each zirconium component is crafted with the highest level of precision, adhering to international standards and tailored to customer-specific requirements.

Zirconium is renowned for its excellent resistance to corrosion, especially in harsh chemical environments, making it a preferred material in industries such as chemical processing, aerospace, and nuclear energy. At Shaanxi Peakrise Metal, we take pride in our comprehensive manufacturing processes, which combine advanced CNC machining with the unique properties of zirconium to create components that meet the highest standards of performance and reliability.

As an industry leader in non-ferrous metal manufacturing, Shaanxi Peakrise Metal Co., Ltd. provides solutions that cater to a wide range of applications. From custom designs to high-volume production, we are equipped to meet the evolving needs of our clients while maintaining the highest standards of quality and precision. Our Zirconium CNC Machined Components are a testament to our commitment to excellence, offering unmatched performance in critical applications.

|

|

|

|

|

|

|

|

|

Product Specifications

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

We can process any shape molybdenum parts according to drawing. Small tolerances and high precision.

We are a manufacturer of molybdenum ,tungsten ,tantalum ,niobium,zirconium products in China, In addition to conventional products, such as plates, rods, wires, tubes, foils, etc., we can also process various special-shaped parts, crucibles, hangers, protective tubes, etc.

Product Features:

-

Corrosion Resistance: Zirconium’s remarkable resistance to corrosive environments, including acids, alkalis, and seawater, ensures a longer lifespan for components, reducing maintenance costs in critical applications.

-

High Temperature Stability: Zirconium components maintain their mechanical integrity at elevated temperatures, making them suitable for high-temperature environments such as chemical processing and aerospace industries.

-

Precision Machining: Our CNC machining processes ensure precise dimensional accuracy, smooth surface finishes, and high consistency, critical for components used in precision-demanding industries.

-

Biocompatibility: Due to its non-toxic nature, zirconium is widely used in medical implants and devices, ensuring safety and performance.

-

Strength and Durability: Zirconium's mechanical strength, combined with its resistance to wear and tear, ensures high performance under extreme operational conditions.

Product Applications:

-

Chemical Processing: Zirconium’s resistance to corrosive chemicals makes it ideal for use in reactors, heat exchangers, and piping systems in chemical plants.

-

Nuclear Industry: Zirconium is a key material used in nuclear reactors, particularly for cladding fuel rods, as it has a low neutron absorption rate and high corrosion resistance.

-

Aerospace Industry: Its high strength-to-weight ratio and resistance to extreme temperatures make zirconium components suitable for aerospace engines, structural components, and fuel systems.

-

Medical Industry: Zirconium’s biocompatibility makes it a preferred material for surgical instruments and implants.

-

Defense and Military: Used in advanced military applications for its strength, resistance to harsh environments, and ability to withstand extreme stress conditions.

|

|

Manufacturing Process:

At Shaanxi Peakrise Metal, our manufacturing process for Zirconium CNC Machined Components involves several critical steps:

- Material Sourcing: We source high-purity zirconium to ensure superior performance and durability.

- Precision CNC Machining: Using state-of-the-art CNC machinery, we machine zirconium components to exact specifications.

- Quality Control: Each component undergoes rigorous testing, including dimensional accuracy, surface finish, and mechanical properties.

- Surface Treatment: Final surface treatments are applied based on the intended application, ensuring optimal performance and longevity.

- Packaging and Delivery: We carefully package components to prevent damage during transportation, ensuring they arrive in perfect condition.

|

|

|

|

|

|

|

|

|

|

Why Choose Shaanxi Peakrise Metal Co., Ltd.?

-

Expertise in Non-Ferrous Metals: With over a decade of experience, we specialize in producing high-quality zirconium and other non-ferrous metal components for various industries.

-

State-of-the-Art Equipment: Our advanced production facilities, including CNC machines, vacuum arc furnaces, and precision testing equipment, ensure top-tier product quality.

-

Global Reach: We have established long-term relationships with clients across the globe, from the United States to Germany, South Korea, and beyond, providing high-quality products to meet international standards.

-

Custom Solutions: Our in-house engineering team can design and produce custom zirconium components to meet the unique needs of each customer.

-

Comprehensive Quality Control: Our stringent quality control measures ensure that every product we deliver meets the highest standards of performance and reliability.

OEM/ODM Services:

Shaanxi Peakrise Metal Co., Ltd. offers flexible OEM and ODM services, allowing customers to customize zirconium components to their exact specifications. From initial design consultation to final production, our team works closely with clients to ensure their specific needs are met.

|

|

|

Frequently Asked Questions (FAQs):

-

What is the lead time for custom zirconium components?

Our standard lead time for custom CNC-machined zirconium components is 4-6 weeks, depending on the complexity of the order. -

Do you provide material certifications?

Yes, we provide material certifications and testing reports with all of our products to ensure compliance with international standards. -

What are your shipping options?

We offer various shipping options, including sea freight, air freight, and express courier services, depending on your location and needs. -

Can you produce prototypes?

Yes, we offer prototype production services to help customers validate designs before moving into full-scale production. -

What industries do you serve?

We serve a wide range of industries, including chemical processing, aerospace, nuclear, medical, and defense.

Packaging and Logistics:

- Packaging Options:

- Wooden crates for heavy-duty protection.

- Foam-filled cartons for additional cushioning.

- Waterproof and moisture-proof packaging.

- Custom packaging tailored to customer requirements.

- Logistics:

- Sea freight for bulk orders.

- Air freight for urgent shipments.

- Multimodal transportation for complex deliveries.

- Express courier for small orders or prototypes.

|

|

|

|

|

|

|

|

|

|

Contact Us:

Interested in high-performance Zirconium CNC Machined Components? Shaanxi Peakrise Metal Co., Ltd. is here to meet your needs. Contact us today to discuss your project requirements or request a custom quote at info@peakrisemetal.com. Let’s create solutions that drive your business forward!

By following this detailed structure, the product page will cater to potential buyers and enhance SEO, attracting and converting customers.

YOU MAY LIKE

-

VIEW MORE50ml 1mm thickness pure zirconium crucible

VIEW MORE50ml 1mm thickness pure zirconium crucible -

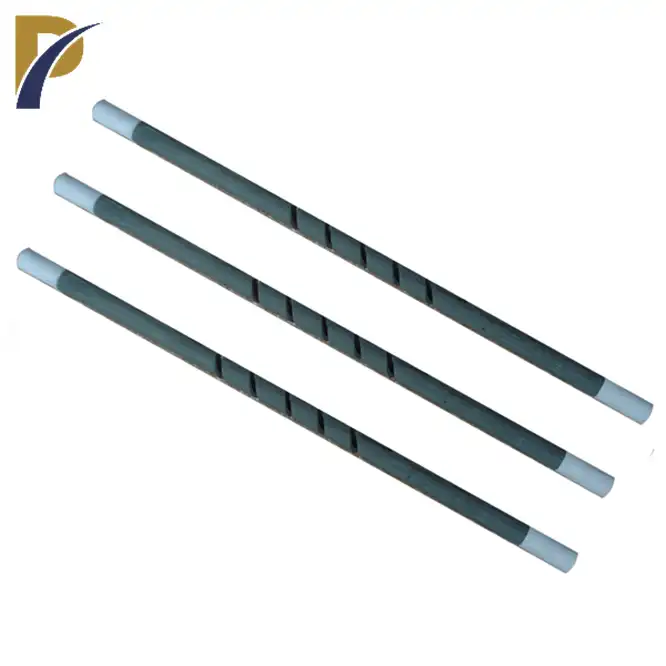

VIEW MOREHigh density straight silicon carbide sic heating elements

VIEW MOREHigh density straight silicon carbide sic heating elements -

VIEW MORESingle thread silicon carbon rod heating element sic heater elements

VIEW MORESingle thread silicon carbon rod heating element sic heater elements -

VIEW MOREZr702 Zirconium Wire

VIEW MOREZr702 Zirconium Wire -

VIEW MOREUltra-Thin Zirconium Metal Foil

VIEW MOREUltra-Thin Zirconium Metal Foil -

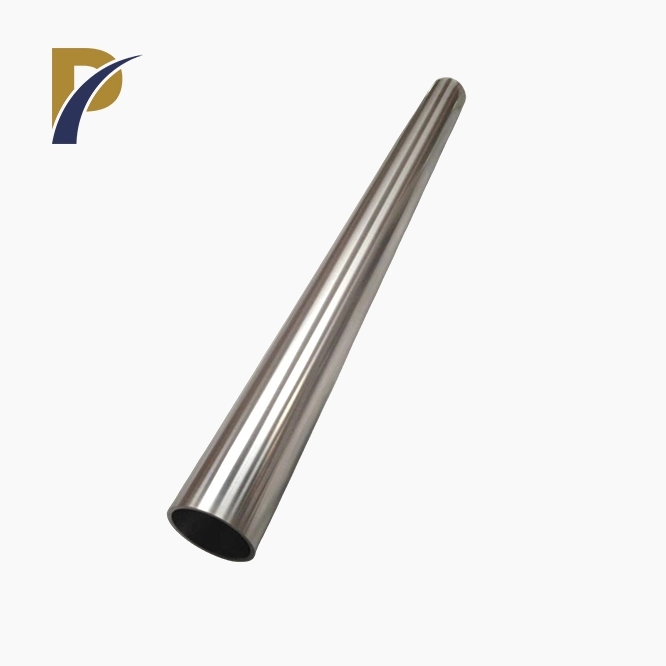

VIEW MOREASTM B523 Zirconium Seamless Tube

VIEW MOREASTM B523 Zirconium Seamless Tube -

VIEW MOREPremium Zirconium Crucible for Lab Use

VIEW MOREPremium Zirconium Crucible for Lab Use -

VIEW MORECustom-Made Zirconium Parts

VIEW MORECustom-Made Zirconium Parts