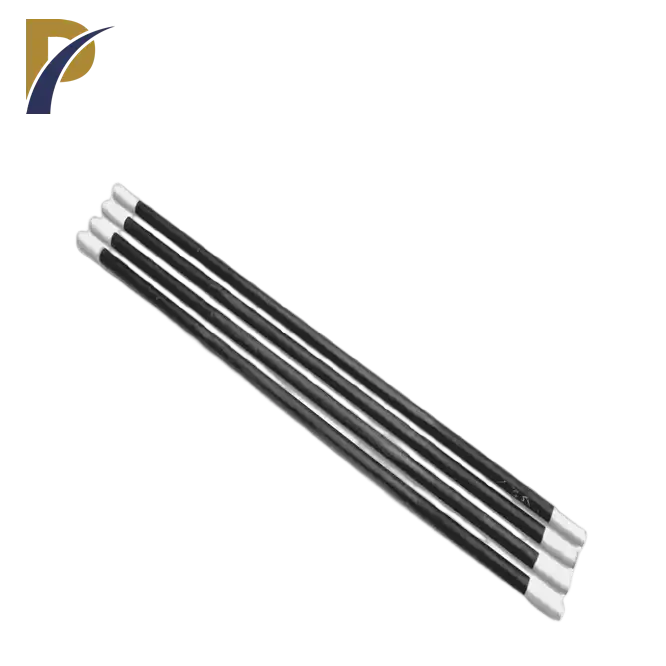

High density straight silicon carbide sic heating elements

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction: Silicon Carbide (SiC) Heating Elements

High-density straight silicon carbide (SiC) heating elements are widely used in industrial heating applications due to their exceptional thermal properties. These elements are highly effective in high-temperature furnaces and kilns because they provide efficient heating and durability.

At Shaanxi Peakrise Metal Co., Ltd., we are a leading global supplier of silicon carbide (SiC) heating elements. With years of experience in producing non-ferrous metals and their alloys, we have built a reputation for providing high-performance heating solutions to industries worldwide. Our SiC heating elements are designed with precision and undergo rigorous testing to ensure optimal performance even in the most demanding conditions. By leveraging our in-house research and development capabilities, we are able to meet the growing needs of modern industries while maintaining the highest standards of quality and reliability.

With a broad range of silicon carbide heating element options, including custom configurations, we cater to diverse industrial requirements, ensuring efficiency and cost-effectiveness in all applications. Our expertise, advanced production facilities, and strong commitment to customer satisfaction make us the preferred partner for businesses worldwide.

|

|

Product Parameters Table

| Parameter | Value | Unit |

|---|---|---|

| Maximum Operating Temp. | 1600 | °C |

| Resistance Tolerance | ±5 | % |

| Diameter Range | 10 - 50 | mm |

| Length Range | 200 - 3000 | mm |

| Electrical Conductivity | 10^-4 | S/m |

| Density | 3.1 | g/cm³ |

| Parameter | Value | Unit |

|---|---|---|

| Thermal Conductivity | 120 | W/m·K |

| Specific Heat Capacity | 700 | J/kg·K |

| Melting Point | 2730 | °C |

| Oxidation Resistance | High | - |

| Thermal Expansion Coeff. | 4.5 | μm/m·K |

| Parameter | Value | Unit |

|---|---|---|

| Tensile Strength | 500 | MPa |

| Fracture Toughness | 3.5 | MPa·m½ |

| Elastic Modulus | 410 | GPa |

| Electrical Resistivity | 10 | Ω·cm |

| Service Life | 5000+ | hours |

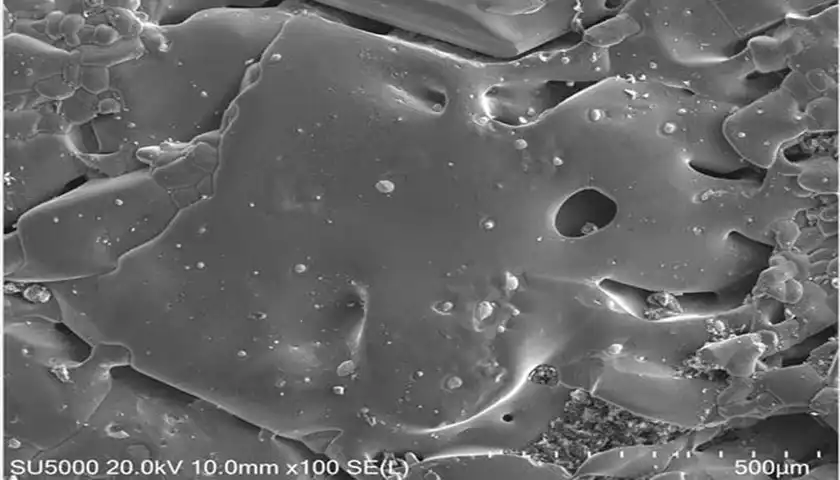

Physical and Mechanical Properties

Silicon carbide (SiC) is known for its outstanding thermal conductivity, which makes it an excellent material for heating elements in high-temperature applications. The material's high strength and resistance to thermal shock ensure that these elements can operate at extreme temperatures without cracking or degrading. The SiC heating elements also exhibit excellent oxidation resistance, ensuring a longer operational life in oxygen-rich environments.

- High Temperature Capability: SiC heating elements can operate at temperatures up to 1600°C (2912°F) in air and even higher in a controlled atmosphere.

- Thermal Shock Resistance: Silicon carbide is resistant to thermal shock, making these elements capable of enduring rapid heating and cooling cycles without cracking or breaking.

- Long Lifespan: SiC elements have a longer service life compared to metallic heating elements, particularly in harsh environments like oxidizing or reducing atmospheres.

- High Power Output: Due to their high electrical resistance, SiC elements can deliver large amounts of power efficiently, making them suitable for high-density heating applications.

- Corrosion Resistance: SiC is chemically stable and can resist corrosion from acidic gases and other chemicals that might be present in industrial environments.

- Straight Elements Design: The straight design simplifies installation and replacement in furnaces. These elements are typically used in electric resistance furnaces, glass melting, and ceramics production.

|

|

Product Functions

-

Efficient Heat Transfer: Silicon carbide heating elements efficiently convert electrical energy into heat, making them ideal for applications where consistent and uniform heating is required.

-

High Temperature Resistance: The elements can operate at temperatures as high as 1600°C, providing reliable performance in extreme conditions.

-

Low Thermal Expansion: With a low thermal expansion coefficient, SiC elements remain stable and resistant to cracking or warping under temperature fluctuations.

-

Customizable Resistance: The resistance values of SiC heating elements can be tailored to meet specific application needs, providing flexibility in design and installation.

Product Applications

Silicon carbide heating elements find widespread applications across various industries due to their unique properties. They are particularly effective in environments that require stable and high temperatures.

-

Ceramics and Glass Manufacturing: SiC elements are commonly used in kilns and furnaces where high heat is required to melt or form ceramics and glass products. Their efficiency helps in reducing energy consumption while providing consistent results.

-

Metallurgy: In the metalworking industry, SiC heating elements are used for heat treatment processes, including annealing and sintering of metals. Their ability to maintain stable high temperatures makes them essential in producing high-quality metal products.

-

Chemical Processing: SiC heating elements are used in chemical reactors and processing equipment that require high heat to initiate or sustain chemical reactions. Their resistance to corrosion by aggressive chemicals further enhances their applicability.

-

Semiconductor Industry: In semiconductor manufacturing, SiC heating elements are used in high-temperature diffusion furnaces, contributing to the production of integrated circuits and other electronic components.

|

|

Product Process and Production Flow

-

Material Selection: High-quality silicon carbide powders are sourced and inspected to meet strict quality standards.

-

Mixing and Forming: The powders are mixed with binding agents and shaped into the desired element configuration through extrusion or molding processes.

-

Sintering: The formed elements are sintered in a high-temperature furnace to strengthen the structure and enhance its electrical and mechanical properties.

-

Final Inspection: Each SiC heating element undergoes rigorous testing to ensure it meets performance standards, including electrical resistance, mechanical strength, and dimensional accuracy.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is equipped with state-of-the-art production facilities, including sintering furnaces, vacuum arc melting furnaces, and advanced CNC machinery. Our team of experienced engineers ensures that each product meets the highest quality standards through a strict quality control process. Our factory’s capacity allows us to handle large-volume orders while maintaining timely deliveries and competitive pricing.

|

|

Logistics and Packaging

-

Packaging Options:

- Wooden crates for heavy-duty protection during transportation.

- Carton boxes with foam padding for smaller components.

- Waterproof and moisture-proof packaging to ensure product integrity in transit.

- Custom packaging available upon request.

- All packaging materials conform to international shipping standards.

-

Logistics Services:

- Sea Freight: Ideal for bulk orders.

- Air Freight: Fast delivery for urgent shipments.

- Land Transport: Reliable transportation within local and neighboring regions.

- Multimodal Transport: Seamless integration of different transport methods.

- Courier Services: Available for small or time-sensitive packages.

|

|

Why Choose Us

- Extensive Experience: With over a decade of experience in non-ferrous metal production, we have earned the trust of customers worldwide.

- Advanced Technology: Our cutting-edge production equipment ensures the highest product quality.

- Custom Solutions: We offer OEM/ODM services to meet the specific requirements of our clients.

- Global Reach: Our products are exported to various countries, including the U.S., Germany, and Australia.

- Commitment to Quality: We adhere to strict ISO 9001 standards, ensuring consistent quality and reliable performance.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. provides flexible OEM/ODM services, allowing customers to tailor silicon carbide heating elements to their exact specifications. From design to production, we work closely with our clients to deliver custom solutions that meet their unique needs.

|

|

FAQ

-

What is the maximum operating temperature of SiC heating elements? SiC heating elements can operate up to 1600°C, making them suitable for high-temperature applications.

-

Can you customize the dimensions of SiC heating elements? Yes, we offer customizable options for length, diameter, and resistance to meet specific application requirements.

-

How long do SiC heating elements typically last? On average, our SiC heating elements have a service life of over 5000 hours, depending on usage conditions.

-

What industries are your SiC heating elements used in? They are used in industries such as ceramics, metallurgy, chemical processing, and semiconductor manufacturing.

-

Do you offer OEM/ODM services? Yes, we provide full customization services to meet the unique needs of our clients.

Contact Us

For more information on silicon carbide (SiC) heating elements and to explore how Shaanxi Peakrise Metal Co., Ltd. can assist your business, please contact us at info@peakrisemetal.com. We look forward to partnering with global buyers and delivering high-quality heating solutions tailored to your needs.