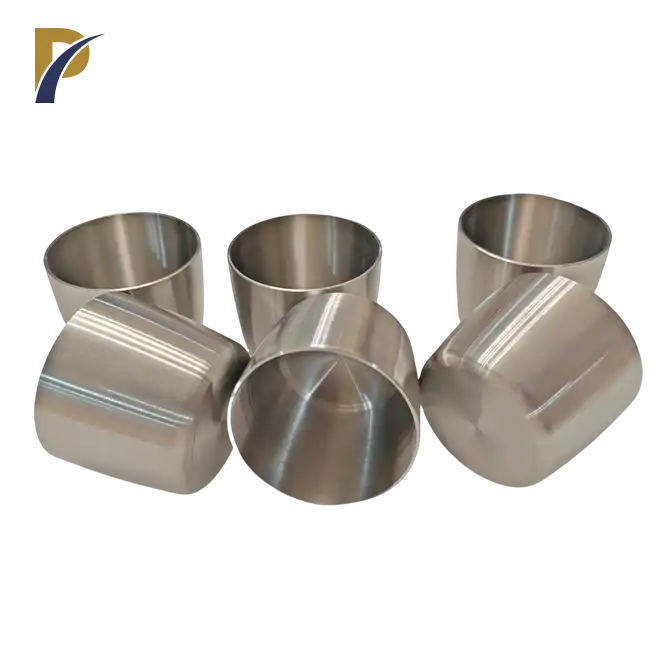

Premium Zirconium Crucible for Lab Use

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Premium Zirconium Crucible for Lab Use by Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

In scientific research and industrial applications, the need for materials that can withstand extreme temperatures and corrosive environments is crucial. Zirconium crucibles have become a standard solution in laboratories across the globe, thanks to their exceptional thermal stability and resistance to chemical corrosion. At Shaanxi Peakrise Metal Co., Ltd., we are proud to offer Premium Zirconium Crucibles for laboratory use, designed for the most demanding experimental and production conditions. Our zirconium crucibles are manufactured to precise specifications, ensuring they deliver consistent performance in every test or process they are used in.

Zirconium's unique properties make it an ideal choice for applications requiring exposure to high temperatures, aggressive chemicals, and corrosive gases. As a global leader in the production of non-ferrous metals, including zirconium, we at Shaanxi Peakrise Metal Co., Ltd. leverage our advanced manufacturing technologies to deliver top-quality zirconium crucibles to laboratories and industries worldwide. With years of experience and a commitment to quality, we provide reliable and durable zirconium products that meet the highest standards.

Whether you are conducting chemical reactions, melting metals, or working with volatile compounds, our premium zirconium crucibles offer superior protection and performance, making them the go-to choice for professionals in scientific research, metallurgy, and industrial applications. Our ability to customize products to specific client needs further sets us apart, offering unparalleled flexibility in design and production.

Product Parameters

| Name: | Zirconium Crucible ZC35 Zr702 Zr Crucible For Lab Use |

| Material: | Zirconium & Zirconium alloy |

| Grade: | Zr702,Zr705,RO60001,RO60901 |

| Density: | 6.51g/cm3 |

| Shape: | Crucible |

| Type: | Low form zirconium crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible. |

| Volume: | 5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml,50ml etc, |

| Custom | Yes, process as per customer's drawing. |

| Wall thickness: | 1mm,2mm,or custom |

| Service life: | A crucible with a wall thickness of 2mm has a longer service life than a thin-walled crucible and can be used repeatedly for more than 100 times. |

| Property | Value |

|---|---|

| Density | 6.49 g/cm³ |

| Electrical Resistivity | 40-50 µΩ·cm |

| Thermal Expansion | 5.7 x 10⁻⁶/K |

| Young’s Modulus | 97 GPa |

| Tensile Strength | 330 MPa |

| Type | Zirconium Crucible |

|---|---|

| Chemical Composition | Zr ≥ 97%, Hf ≤ 4.5% |

| Application Range | Lab, industrial use |

| Corrosion Resistance | Excellent |

| Compatibility | High-temp environments |

| Shape | Cylindrical, Custom |

Physical and Chemical Properties

Zirconium crucibles are highly resistant to corrosion, particularly in oxidizing atmospheres. Their chemical stability makes them ideal for use in experiments involving reactive chemicals. Moreover, they offer excellent resistance to alkalis and acids, making them versatile for various laboratory and industrial processes. They can withstand temperatures up to 2400°C, making them suitable for high-temperature applications in metallurgy and chemical research.

|

|

Key Properties:

- High melting point of 1855°C

- Excellent corrosion resistance, especially in acidic environments

- Low thermal expansion, reducing the risk of cracking

- High thermal conductivity ensures even heat distribution

- High purity zirconium (99.9%), minimizing contamination risks

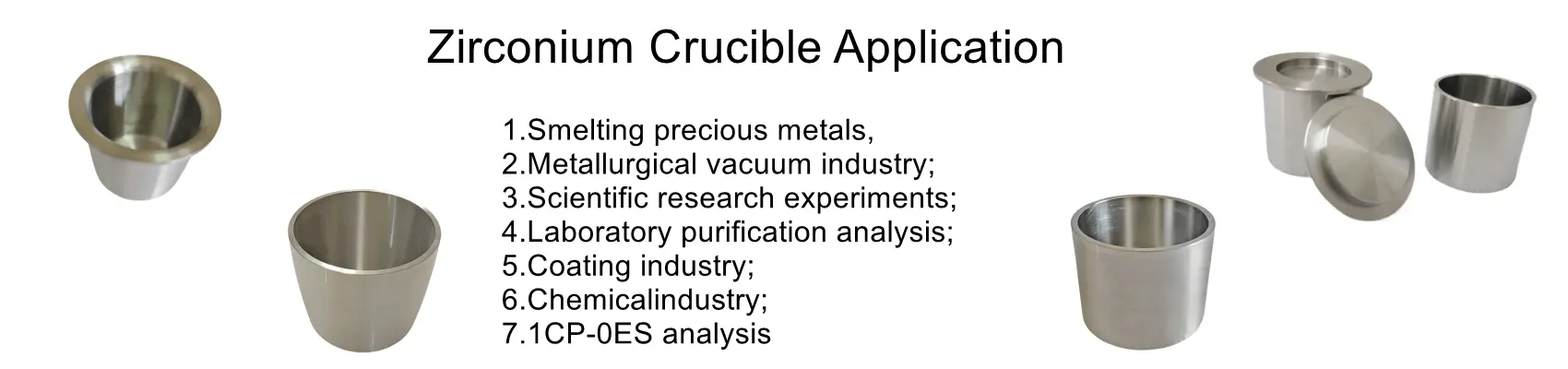

Product Applications

-

High-Temperature Metallurgical Processes: Zirconium crucibles are widely used in metallurgical industries for melting and refining metals. Their ability to withstand extreme temperatures ensures a smooth melting process without material contamination.

-

Chemical Research: Laboratories conducting chemical analysis and reactions rely on zirconium crucibles for their resistance to corrosive chemicals and high heat. These crucibles are often used in the study of new materials and chemical compounds.

-

Nuclear Energy: Zirconium's low absorption cross-section for thermal neutrons makes it a valuable material in nuclear energy applications, where it is used in high-temperature reactions and processes.

-

Material Science: In the development of new materials, zirconium crucibles provide a stable environment for experiments involving volatile or reactive chemicals, as well as for melting or alloying different metals.

-

Glass and Ceramics Production: Zirconium crucibles are used in the production of glass and ceramics, where high-temperature stability and resistance to corrosion are essential for the melting and mixing of raw materials.

Production Process

Our zirconium crucibles are manufactured using a series of rigorous processes to ensure they meet the highest industry standards. The process begins with the purification of zirconium, followed by casting or forming the crucibles through vacuum arc melting or plasma electron beam melting. Each crucible is subjected to vacuum annealing to ensure material stability and durability. The final step includes rigorous testing to confirm that the crucibles meet the necessary specifications for use in high-temperature and corrosive environments.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

-

Expertise: With over a decade of experience in non-ferrous metal production, we are industry leaders in zirconium crucibles and other high-performance materials.

-

Advanced Technology: Our state-of-the-art production facilities, including vacuum arc melting and plasma electron beam melting, ensure that every crucible we produce meets stringent quality standards.

-

Customization: We offer OEM and ODM services, allowing us to tailor zirconium crucibles to your specific requirements.

-

Global Reach: With customers in Taiwan, Ukraine, South Korea, the United States, and other countries, we have a proven track record of delivering high-quality products worldwide.

-

Quality Assurance: All of our products undergo rigorous testing to ensure they meet the required specifications for high-performance applications.

Packaging

- Wooden Crates: Ideal for long-distance transport, providing sturdy protection against external shocks.

- Cardboard Boxes: For smaller quantities, ensuring lightweight but effective packaging.

- Foam Padding: Provides additional protection by cushioning the crucibles during shipping.

- Waterproof Packaging: Ensures the crucibles are protected from moisture and humidity during transit.

- Custom Packaging: Tailored packaging solutions are available upon request, ensuring your product is delivered safely and securely.

|

|

Shipping

- Sea Freight: Cost-effective for bulk orders with delivery timelines suited to your production needs.

- Air Freight: For time-sensitive deliveries, we offer air freight services to ensure fast delivery.

- Land Transport: Available for domestic or regional deliveries.

- Multi-modal Transport: Combining different modes of transport to provide the most efficient shipping solution.

- Express Delivery: For smaller, urgent orders, express shipping options are available.

FAQ

-

What is the maximum operating temperature of zirconium crucibles?

Zirconium crucibles can withstand temperatures up to 2400°C, making them ideal for high-temperature applications. -

How do I clean the crucible after use?

Clean zirconium crucibles using mild acids or alkalis, depending on the residues. Avoid mechanical abrasives that may damage the surface. -

Can you customize the size of the crucibles?

Yes, we offer custom sizes based on your specific needs. Please contact us with your requirements. -

What is the lead time for orders?

Lead times vary depending on the order size and customization needs. Generally, our lead time is 2-4 weeks for standard products. -

Do you provide samples?

Yes, we provide samples upon request. Contact us for more details.

Contact us today!

Shaanxi Peakrise Metal Co., Ltd. is your trusted supplier of premium zirconium crucibles for lab use. We welcome inquiries from global buyers and partners. Whether you're looking for high-quality stock products or customized solutions, our team is here to assist. Reach out to us at info@peakrisemetal.com to discuss your specific needs and let us help you find the perfect zirconium solution for your lab or industrial application!