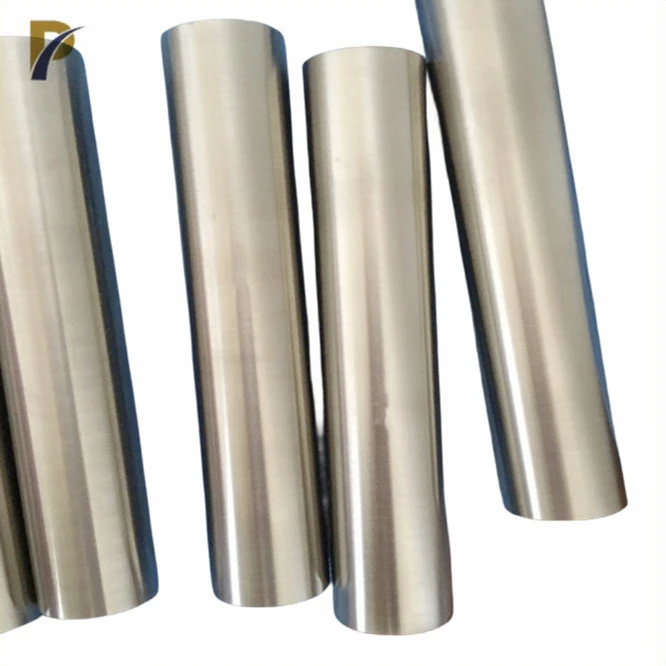

tzm molybdenum alloy bar

Diameter: 2-200mm

Length: 10-250mm

Density: 10.22g·cm-3

Elongation: 20%

Melting Point : 2617℃

Yield Strength: 560~1150MPa

Tensile Strength: 685MPa

Resistivity: (5.3~5.5)X10-8 Ω·m

Standard: ASTM B387

PRODUCT DESCRIPTION

TZM Molybdenum Alloy Bar Product Introduction for Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

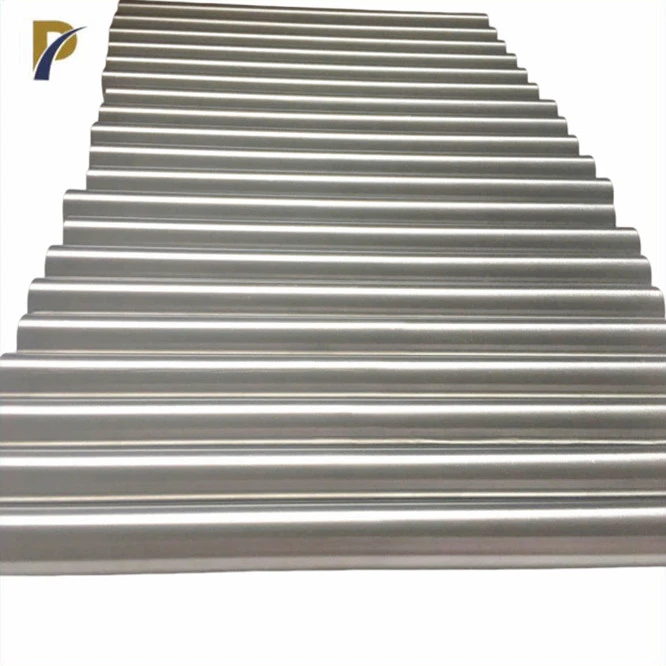

TZM (Titanium-Zirconium-Molybdenum) molybdenum alloy bars are widely recognized in industries requiring high-temperature resistance, superior strength, and excellent wear resistance. TZM alloys are ideal for applications in aerospace, defense, nuclear industries, and other high-performance environments. The combination of molybdenum with small percentages of titanium and zirconium offers significant improvements in tensile strength, hardness, and creep resistance at elevated temperatures compared to pure molybdenum.

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of TZM molybdenum alloy bars. As an experienced and reliable supplier, we specialize in producing high-quality non-ferrous metals and alloys, including molybdenum and its derivatives like TZM alloy. With over a decade of experience in the field, we serve global customers with customized solutions, from material selection to product manufacturing, ensuring high standards and competitive pricing. Our products are widely used and recognized in countries like the United States, South Korea, and Germany.

Product Parameters

| Diameter inches(mm) | Tolerance in inches (mm) | ||

| Diameter | Out of Roundness | ||

| + | - | ||

| 0.020~1/16 (0.51~1.59) | 0.001(0.02) | 0.001(0.02) | 0.001(0.02) |

| ≥1/16~9/32 (1.59~7.14) | 0.002(0.05) | 0.002(0.05) | 0.004(0.10) |

| ≥9/32~13/32 (7.14~10.32) | 0.010(0.25) | 0.005(0.13) | 0.008(0.20) |

| ≥13/32~5/8 (10.32~15.9) | 0.010(0.25) | 0.005(0.13) | 0.012(0.30) |

| ≥5/8~7/8 (15.9~22.2) | 0.015(0.38) | 0.005(0.13) | 0.015(0.38) |

| ≥7/8~1 (22.2~25.4) | 0.020(0.51) | 0.005(0.13) | 0.015(0.38) |

| ≥1~11/8 (25.4~34.9) | 0.020(0.51) | 0.010(0.25) | 0.018(0.46) |

| ≥11/8~3/2 (34.9~38.1) | 0.020(0.51) | 0.015(0.38) | 0.020(0.51) |

| ≥3/2~13/8 (38.1~41.3) | 0.025(0.64) | 0.015(0.38) | 0.020(0.51) |

| ≥13/8~2 (41.3~50.8) | 0.030(0.76) | 0.020(0.51) | 0.025(0.64) |

| ≥2~5/2 (50.8~63.5) | 0.032(0.81) | 0.032(0.81) | 0.025(0.64) |

| ≥5/2~13/4(63.5~82.6) | 0.032(0.81) | 0.032(0.81) | 0.027(0.69) |

| ≥13/4~7/2 (82.6~88.9) | 0.045(1.14) | 0.045(1.14) | 0.040(1.02) |

Physical and Mechanical Properties

TZM alloy bars boast outstanding physical and mechanical properties, making them the preferred choice for demanding applications. These include:

- High Temperature Resistance: The alloy retains its mechanical integrity at temperatures exceeding 1200°C, outperforming pure molybdenum.

- Excellent Tensile Strength: With a tensile strength of up to 780 MPa, TZM bars are ideal for high-stress applications.

- Creep Resistance: The addition of titanium and zirconium enhances the alloy’s resistance to deformation under prolonged exposure to heat.

- Hardness: With Vickers hardness values between 220-260 HV, TZM alloy bars offer enhanced resistance to wear and abrasion.

|

|

|

Product Functions

The TZM molybdenum alloy bar delivers excellent performance in the following functions:

- High Temperature Structural Applications: Ideal for use in applications where maintaining structural integrity at high temperatures is essential.

- Wear and Tear Resistance: With its superior hardness, TZM alloy bars provide long-lasting service in abrasive environments.

- Creep Resistance: Provides excellent creep strength in environments with sustained high temperatures, crucial for aerospace and nuclear applications.

- Thermal Conductivity: The alloy’s ability to transfer heat effectively makes it suitable for thermal management components.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

The unique properties of TZM alloy bars make them suitable for various demanding applications, including:

- Aerospace Industry: Used in high-temperature components like turbine blades and rocket nozzles.

- Defense Applications: TZM is used in ballistic shields, armor-piercing ammunition, and missile components.

- Nuclear Power: Its high temperature and radiation resistance make it ideal for nuclear reactor components.

- Furnace Components: Often used in high-temperature furnace elements, including heating elements and supports.

- Metal Processing Tools: Due to its hardness, TZM is used in tools for cutting, forging, and rolling other metals.

|

|

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., the production of TZM molybdenum alloy bars follows a stringent and precise manufacturing process to ensure the highest quality:

- Raw Material Selection: High-purity molybdenum, titanium, and zirconium are selected.

- Vacuum Arc Melting: The alloying process takes place in a vacuum arc furnace to prevent oxidation.

- Forming and Shaping: The alloy is formed into bars using rolling mills and CNC machines for precision.

- Heat Treatment: The bars undergo vacuum annealing to enhance mechanical properties.

- Final Inspection: Each product is thoroughly inspected for quality and dimensional accuracy before being shipped.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is equipped with state-of-the-art production facilities, including vacuum arc melting furnaces, plasma electron beam melting furnaces, rolling mills, and CNC machines. With over a decade of experience in non-ferrous metal production, we offer a wide range of alloys, including tungsten, tantalum, and molybdenum products. Our factory is ISO9001 certified, ensuring that all production processes meet international quality standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

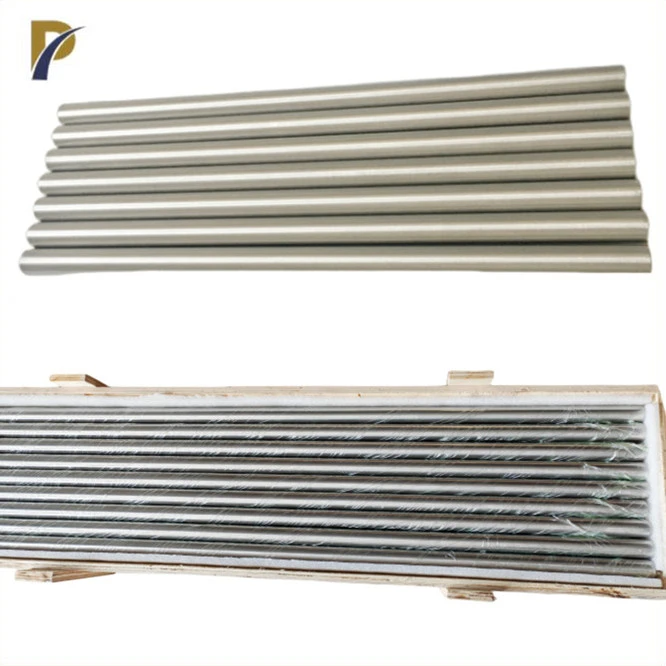

Logistics and Packaging

Packaging Options:

Wooden crates

Foam-filled boxes

Waterproof and moisture-proof packaging

Custom packaging solutions available

|

|

|

|

|

|

|

|

-

- Logistics Options:

- Sea freight

- Air freight

- Land transport

- Multimodal transport

- Express delivery services (DHL, FedEx, UPS)

Why Choose Us?

- Comprehensive Expertise: We have over a decade of experience in producing non-ferrous metals, including TZM molybdenum alloy bars.

- Advanced Facilities: Our factory boasts cutting-edge production and testing equipment to ensure product quality.

- Global Reach: We export products to major markets like the U.S., Germany, and South Korea.

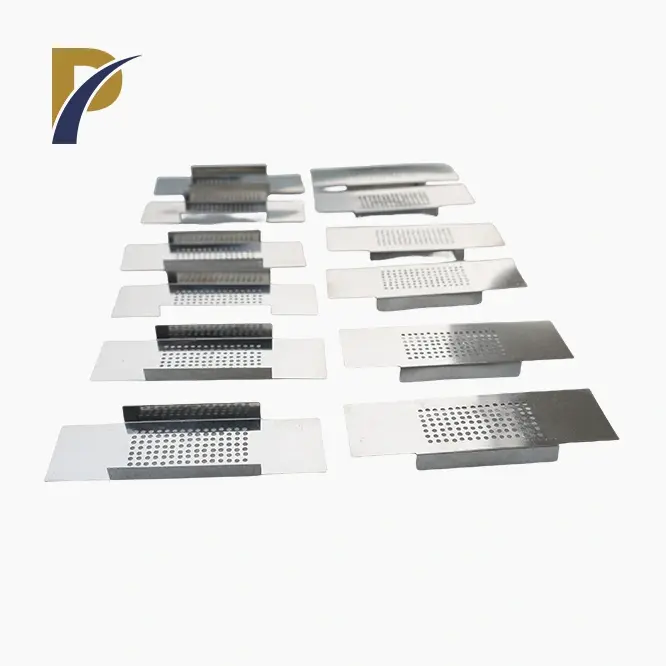

- Customization: We offer OEM and ODM services to meet specific customer requirements.

- Quality Assurance: All products undergo strict quality checks, and we are ISO 9001 certified.

- Customer Satisfaction: Our products are highly recognized and evaluated by clients worldwide.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. supports full OEM and ODM services. We can manufacture TZM molybdenum alloy bars according to your specifications, including custom dimensions, mechanical properties, and finishing. Our R&D team works closely with clients to ensure that all products meet their exact needs.

|

|

|

|

|

|

|

|

|

FAQ

- What is the maximum operating temperature of TZM alloy bars? TZM alloy bars can operate effectively at temperatures up to 1400°C.

- Can TZM alloy be customized to different sizes? Yes, we offer custom sizes and specifications based on your requirements.

- How do you ensure the quality of TZM alloy bars? All our products undergo strict quality control, including composition analysis and mechanical testing.

- What are the lead times for international orders? Lead times vary depending on the order size and destination, but we aim to deliver within 3-4 weeks.

- Do you provide certificates of material composition? Yes, we provide full certification, including composition analysis and mechanical properties.

Contact Us (CTA)

Looking for high-quality TZM molybdenum alloy bars? Shaanxi Peakrise Metal Co., Ltd. is your trusted global supplier. Contact us today at info@peakrisemetal.com to learn more about our products and services. We look forward to collaborating with you on your next project!

YOU MAY LIKE

-

VIEW MOREmolybdenum glass melting electrodes

VIEW MOREmolybdenum glass melting electrodes -

VIEW MOREmolybdenum vacuum boat

VIEW MOREmolybdenum vacuum boat -

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREtungsten welding electrodes

VIEW MOREtungsten welding electrodes -

VIEW MOREtungsten crucible for induction furnace

VIEW MOREtungsten crucible for induction furnace -

VIEW MOREpure tantalum sheet/plate

VIEW MOREpure tantalum sheet/plate -

VIEW MOREwelding titanium tube

VIEW MOREwelding titanium tube