titanium zirconium molybdenum tzm alloy

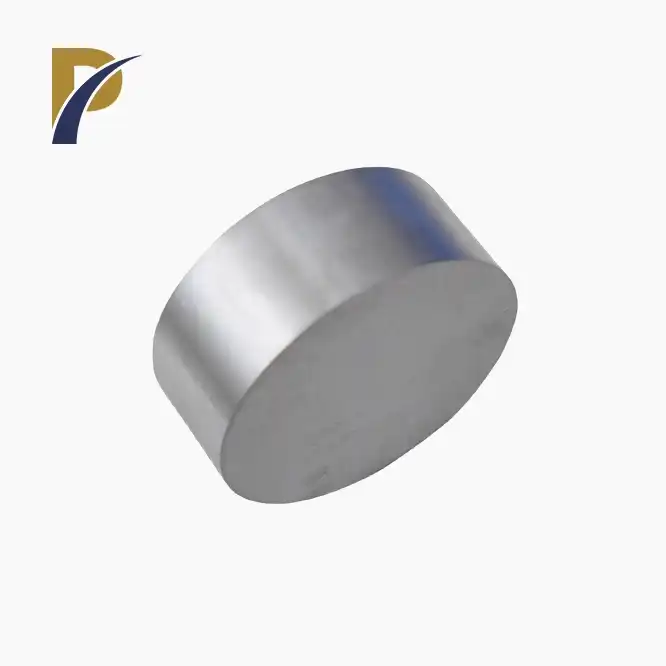

Diameter: 2-200mm

Length: 10-250mm

Density: 10.22g·cm-3

Elongation: 20%

Melting Point : 2617℃

Yield Strength: 560~1150MPa

Tensile Strength: 685MPa

Resistivity: (5.3~5.5)X10-8 Ω·m

Standard: ASTM B387

PRODUCT DESCRIPTION

Titanium Zirconium Molybdenum (TZM) Alloy Product Introduction for Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Titanium Zirconium Molybdenum (TZM) alloy is a high-performance material recognized for its excellent strength, high-temperature resistance, and remarkable machinability. Widely used in industries requiring materials that can withstand extreme conditions, TZM alloy offers superior durability and performance when compared to traditional molybdenum alloys. As a key supplier in the industry, Shaanxi Peakrise Metal Co., Ltd. delivers top-quality TZM alloy products globally, with a focus on high standards in production and customer satisfaction.

Our TZM alloy is engineered for various demanding applications such as aerospace, defense, and nuclear industries, thanks to its superior creep resistance, hardness, and tensile strength at elevated temperatures. With a proven track record of meeting the stringent requirements of these sectors, our TZM alloy continues to be the material of choice for advanced engineering projects worldwide.

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer and supplier of non-ferrous metals, including titanium, zirconium, and molybdenum alloys. We are known for delivering consistent quality and supporting customized solutions for our clients. Our expertise in material research, advanced production processes, and a commitment to innovation allow us to stay at the forefront of the industry.

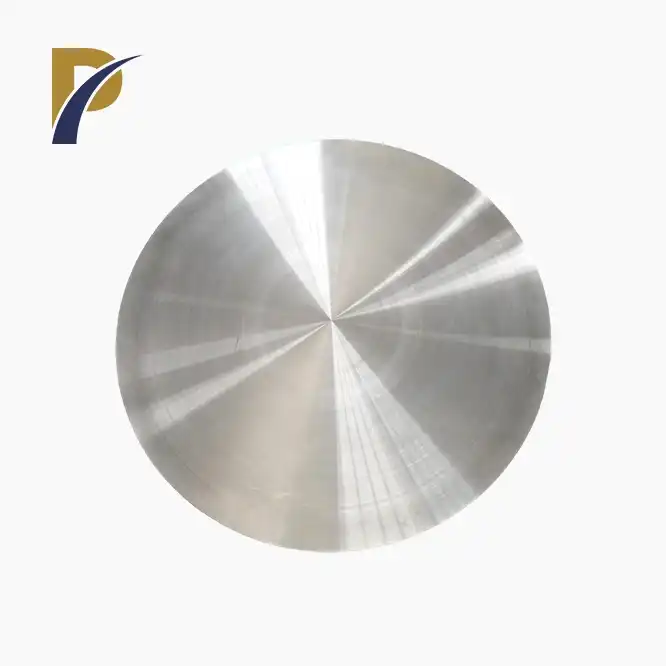

Disc diameter : 20-600mm

Disc thickness: 6-25mm

Surface: black,C.C,bright,polished

Standard: ASTMB 386

Also we can process as per customer's request.

|

|

|

|

|

|

|

|

|

Physical and Mechanical Properties

TZM alloy exhibits a unique combination of properties that makes it ideal for high-temperature applications. These include:

- High Melting Point: With a melting point of 2620°C, TZM can endure extremely high temperatures without losing structural integrity.

- Creep Resistance: TZM has exceptional creep resistance at elevated temperatures, allowing it to maintain strength and stability under long-term mechanical stress.

- Thermal Conductivity: Its excellent thermal conductivity ensures that it effectively disperses heat, reducing the risk of overheating in high-temperature environments.

- Hardness and Strength: The alloy's superior hardness and tensile strength enhance its resistance to deformation under mechanical stress.

- Oxidation Resistance: TZM demonstrates good oxidation resistance, making it suitable for applications in oxygen-rich, high-temperature environments.

| Element | Si | Mn | Ni | Cu | V | Zr | O | P | Fe | Mg |

| Concentration(%) | 0.002 | 0.0009 | 0.0008 | 0.0018 | 0.013 | 0.086 | 0.32 | 0.001 | 0.0011 | 0.0015 |

| Element | Al | Ti | Ca | C | N | |||||

| Concentration(%) | 0.001 | 0.5 | <0.001 | 0.012 | 0.0022 | |||||

| Purity(Metallic Base) Mo≥99.06%(TZM) | ||||||||||

|

Elongation /% |

Elastic Modulus /GPa |

Yield Strength /MPa |

Tensile Strength /MPa |

Fracture Toughness /(MP·m1/2) |

|

<20 |

320 |

560~1150 |

685 |

5.8~29.6 |

Product Applications

TZM alloy’s unique properties allow it to be used across a range of high-stress, high-temperature applications:

- Aerospace: TZM is used in manufacturing aircraft components, rocket nozzles, and structural elements exposed to high temperatures.

- Defense: Due to its high strength and heat resistance, TZM is used in the production of military-grade parts and protective gear.

- Nuclear Industry: TZM’s corrosion and oxidation resistance makes it ideal for fuel rods, reactor components, and other elements exposed to radiation and high temperatures.

- Industrial Furnaces: TZM is frequently used in the construction of furnace parts, such as heating elements and crucibles, due to its ability to withstand extreme heat.

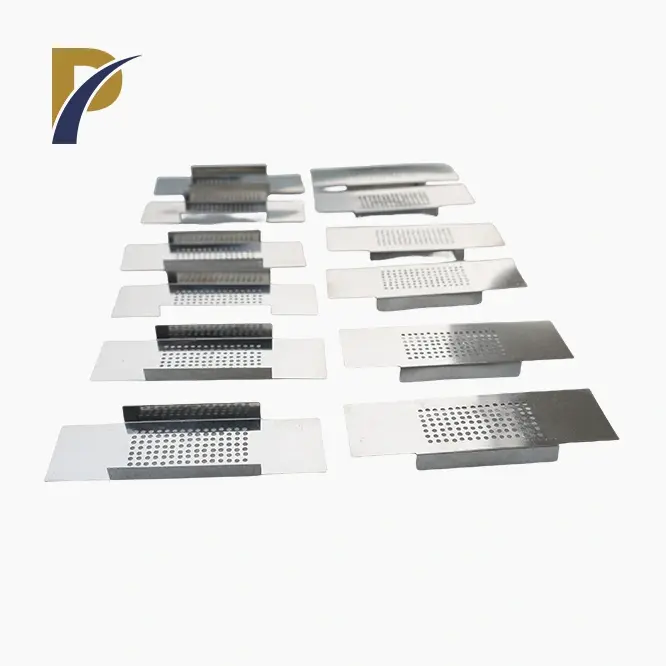

- Tool Manufacturing: The alloy’s strength and machinability make it ideal

|

|

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we utilize advanced manufacturing techniques to produce top-quality TZM alloy products. Our process includes:

- Raw material selection, ensuring the highest purity metals are used.

- Melting in vacuum arc furnaces to achieve homogeneous alloying.

- Rolling, drawing, and forging to achieve the desired product dimensions.

- Precision machining and finishing to meet exact specifications.

- Quality inspection, testing for mechanical and chemical properties to ensure compliance with international standards.

Logistics and Packaging

To ensure safe and efficient delivery, we offer various packaging and shipping options:

- Wooden crate packaging for heavy-duty items.

- Carton and foam-filled packaging for added protection.

- Waterproof and moisture-proof packaging to preserve product integrity.

- Customized packaging solutions tailored to customer requirements. Our logistics network includes:

- Sea freight for large shipments.

- Air freight for urgent orders.

- Land transportation for domestic deliveries.

- Multi-modal transport solutions and express courier services.

Why Choose Us?

Shaanxi Peakrise Metal Co., Ltd. stands out in the industry for several reasons:

- Industry Expertise: With over a decade of experience, we offer deep expertise in non-ferrous metal production.

- Global Reach: We serve clients in over 10 countries, providing reliable products that meet international standards.

- Comprehensive Quality Control: Our ISO 9001-certified system ensures that every product meets stringent quality criteria.

- Advanced Technology: We employ cutting-edge machinery and innovative processes to deliver precise and high-performance products.

- Customer-Centric Approach: We offer customized solutions, responsive customer service, and technical support to meet every client's specific needs.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. supports extensive OEM and ODM services. Our team of engineers and technicians work closely with clients to design and manufacture products that meet their exact specifications. Whether you need custom sizes, shapes, or material compositions, we have the expertise to deliver high-quality, tailored solutions.

|

|

|

|

FAQ

- What are the main benefits of TZM alloy?

TZM alloy offers high-temperature strength, creep resistance, and excellent machinability, making it ideal for demanding applications. - Can I order customized sizes?

Yes, we offer OEM services and can provide TZM products in custom sizes and shapes based on your requirements. - What industries use TZM alloy?

TZM is used in aerospace, defense, nuclear energy, and industrial manufacturing due to its high-temperature and strength properties. - How do you ensure product quality?

We adhere to ISO 9001 standards and conduct thorough testing for mechanical, chemical, and physical properties to ensure top-quality products. - What packaging options are available?

We offer wooden crates, carton packaging, foam-filled protection, and customized packaging solutions to meet your needs.

Contact Us

For more information about our Titanium Zirconium Molybdenum (TZM) alloy or to place an order, please contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com. We welcome inquiries from global purchasers and look forward to establishing long-term partnerships with you.

YOU MAY LIKE

-

VIEW MOREmolybdenum sintering boats

VIEW MOREmolybdenum sintering boats -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREwelding titanium tube

VIEW MOREwelding titanium tube -

VIEW MOREtitanium wire for jewelry

VIEW MOREtitanium wire for jewelry -

VIEW MOREtitanium pipe fittings flange

VIEW MOREtitanium pipe fittings flange -

VIEW MOREzirconium crucible price

VIEW MOREzirconium crucible price -

VIEW MORE2 molybdenum electrodes 1 8 diameter

VIEW MORE2 molybdenum electrodes 1 8 diameter -

VIEW MOREtungsten and molybdenum electrodes

VIEW MOREtungsten and molybdenum electrodes