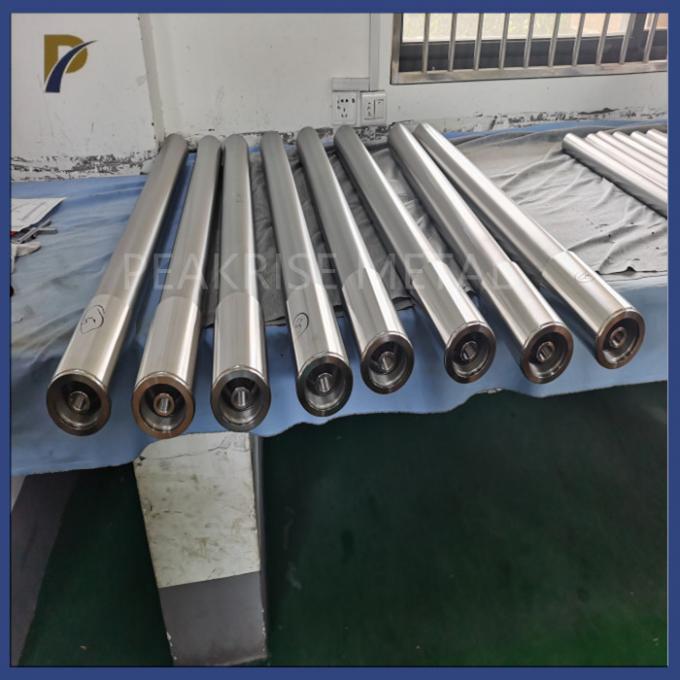

2 molybdenum electrodes 1 8 diameter

Purity: 99.97%

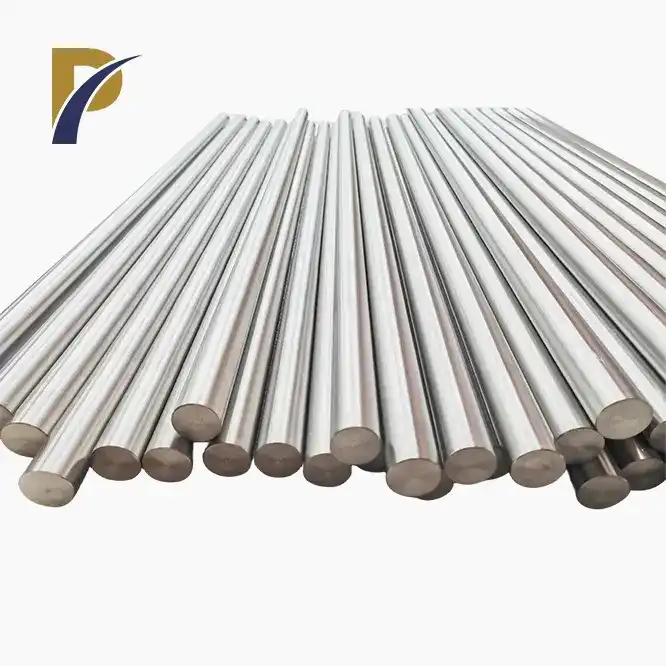

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

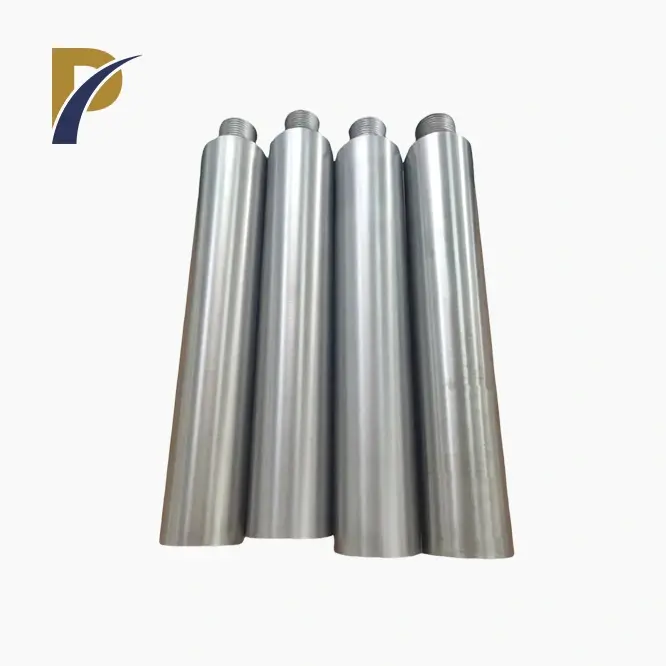

Product Introduction: 2 Molybdenum Electrodes 18 Diameter

Molybdenum electrodes are critical components in high-temperature industrial processes, especially in applications such as glass melting, furnace heating, and the production of electronic materials. Shaanxi Peakrise Metal Co., Ltd. is a leading global supplier of 2 molybdenum electrodes with a diameter of 1/8 inch. Our molybdenum electrodes are renowned for their exceptional electrical conductivity, high melting point, and resistance to corrosion and oxidation, making them ideal for use in extreme environments.

Shaanxi Peakrise Metal Co., Ltd. has built a solid reputation in the non-ferrous metals industry, providing high-quality products to international markets. Our electrodes are manufactured using state-of-the-art equipment and stringent quality control measures. With a focus on precision and performance, our molybdenum electrodes ensure long service life and efficiency in demanding industrial applications.

Our company has been at the forefront of non-ferrous metal production for over a decade, catering to industries ranging from electronics to aerospace. As a trusted supplier, we offer customized solutions and technical support to meet the specific needs of our global clients. Whether you require standard molybdenum electrodes or tailored dimensions, Shaanxi Peakrise Metal Co., Ltd. is committed to delivering superior quality and customer satisfaction.

|

|

|

|

Product Parameters Table

| Molybdenum Melting Glass Molybdenum Electrode | |||||

| Dia [mm] |

tolerance [mm] |

length [mm] |

Surface | Straightness [per m] |

Approx weight [kg/m] |

| 4.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.128 |

| 10.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.801 |

| 20.00 | +/- 0.020 | 2000 | polished | <2.5 | 3.204 |

| 25.00 | +/- 0.040 | 2000 | polished | <2.5 | 5.007 |

| 30.00 | +/- 0.300 | 2000 | Polished | <1.5 | 7.210 |

| 40.00 | +/- 0.300 | 2000 | Polished | <1.5 | 12.818 |

| 50.00 | +/- 0.400 | 2000 | Polished | <1.5 | 20.654 |

| 60.00 | +/- 0.400 | 2000 | Polished | <1.5 | 28.840 |

| 63.50 | +/- 0.400 | 2000 | Polished | <1.5 | 32.303 |

| 70.00 | +/- 0.400 | 2000 | Polished | <1.5 | 39.254 |

| 80.00 | +/- 1.000 | 2000 | Polished | <2.5 | 51.271 |

| 90.00 | +/- 1.000 | 2000 | Polished | <2.5 | 64.890 |

| 100.00 | +/- 1.000 | 2000 | Polished | <2.5 | 80.111 |

| 120.00 | +/- 2.000 | 2000 | Polished | <2.5 | 115.359 |

Physical and Chemical Properties

Molybdenum electrodes possess unique properties that make them suitable for various industrial applications:

- High Melting Point: With a melting point of 2620°C, molybdenum electrodes can withstand extreme temperatures without degrading.

- Superior Electrical Conductivity: Ensuring efficient power transmission in high-temperature environments.

- Corrosion and Oxidation Resistance: The electrodes maintain stability even in corrosive environments, extending their operational life.

- Excellent Mechanical Strength: Molybdenum electrodes exhibit high tensile strength and resistance to deformation under pressure.

Product Functions

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

Molybdenum electrodes are indispensable in several industries:

- Glass Manufacturing: Used in electric melting and glass refining furnaces due to their high-temperature resistance and low reactivity with molten glass.

- Metallurgy: Essential in the production of specialty alloys and metals where precision and stability at high temperatures are crucial.

- Electronics: Molybdenum electrodes serve in the production of semiconductors, where their conductive properties are vital for circuit stability.

- Aerospace: Employed in high-temperature engines and components where extreme heat and wear resistance are necessary.

- Furnace Components: Utilized in vacuum and inert atmosphere furnaces for their ability to maintain performance in low-oxygen environments.

|

|

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we follow a meticulous production process to ensure the quality of our molybdenum electrodes:

- Material Selection: High-purity molybdenum is sourced to meet the stringent standards required for high-performance electrodes.

- Sintering: The molybdenum powder undergoes sintering in a high-temperature furnace to increase density and reduce porosity.

- Forming: The sintered material is shaped into electrodes through precision machining, ensuring dimensional accuracy and smooth surfaces.

- Annealing: To improve ductility and mechanical properties, the electrodes are annealed in a controlled environment.

- Final Inspection: Each electrode undergoes rigorous testing, including electrical conductivity and mechanical strength evaluations, before packaging.

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a modern facility equipped with advanced production and testing equipment. Our production capabilities include:

- Intermediate frequency sintering furnaces

- Vacuum arc melting furnaces

- Laser cutters

- Plasma electron beam melting furnaces

- CNC machines for precision machining

Our factory covers an area of over 10,000 square meters, allowing us to meet large-scale production demands while maintaining stringent quality control standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

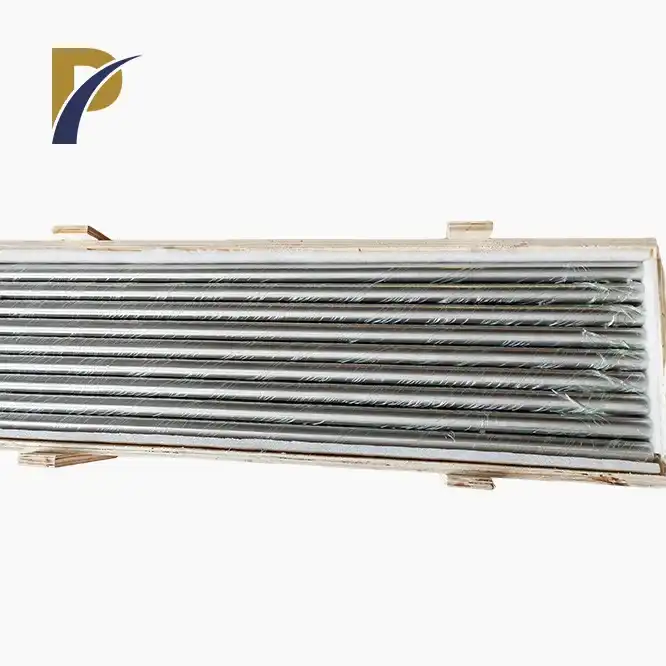

Logistics and Packaging

We ensure that our molybdenum electrodes reach customers in perfect condition by using secure packaging and reliable shipping methods:

- Wooden Crate Packaging: Provides robust protection during transport.

- Carton and Foam Packaging: Used for smaller quantities or sample orders.

- Waterproof and Moisture-Proof Packaging: Ensures that the electrodes are protected from environmental damage during transit.

- Custom Packaging: Available upon request to meet specific customer needs.

|

|

|

|

|

|

|

|

We offer flexible logistics options, including:

- Sea Freight: Cost-effective for bulk shipments.

- Air Freight: Fast and reliable for urgent orders.

- Land Transport: For nearby regions.

- Multimodal Transport: Combining various shipping methods for optimal delivery.

- Courier Services: Available for sample or small-quantity orders.

Why Choose Us?

- Industry Expertise: Over a decade of experience in non-ferrous metals production.

- Advanced Equipment: Equipped with the latest technology for manufacturing high-quality molybdenum electrodes.

- Global Reach: Our products are exported to the United States, Europe, Asia, and beyond, with a strong international presence.

- Custom Solutions: We offer OEM and ODM services to meet the specific requirements of our clients.

- Quality Assurance: All products are manufactured under ISO 9001:2015 quality management standards.

-

What is the lead time for molybdenum electrodes?

- Our typical lead time is 2-4 weeks, depending on the order quantity and customization requirements.

-

Do you offer custom sizes for molybdenum electrodes?

- Yes, we provide custom dimensions to meet the specific needs of our clients.

-

What packaging options do you offer?

- We offer a variety of packaging solutions, including wooden crates, foam-filled cartons, and custom options.

-

Are your electrodes tested for quality?

- Yes, each electrode undergoes rigorous testing to ensure electrical conductivity and mechanical strength.

-

Do you ship internationally?

- Yes, we ship to countries worldwide, including the US, Europe, and Asia.

Contact Us

For more information about our 2 molybdenum electrodes with 18 diameter or to place an order, please contact us at info@peakrisemetal.com. We look forward to partnering with you to meet your non-ferrous metal needs.