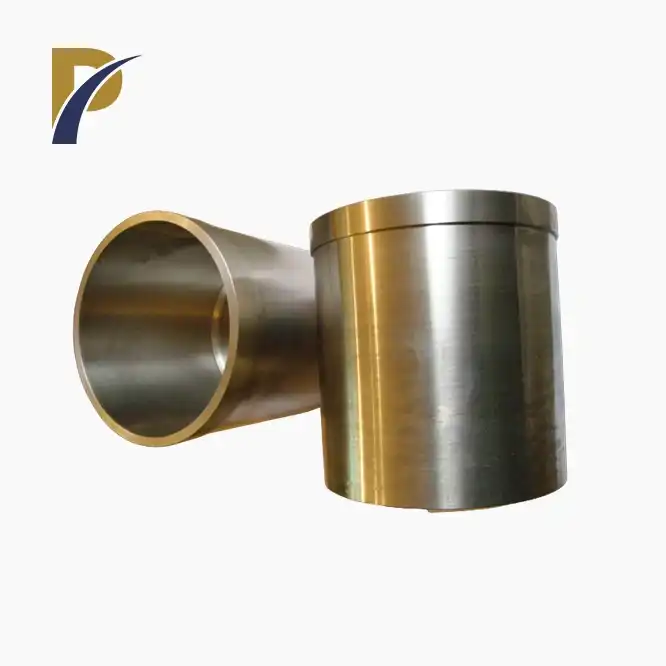

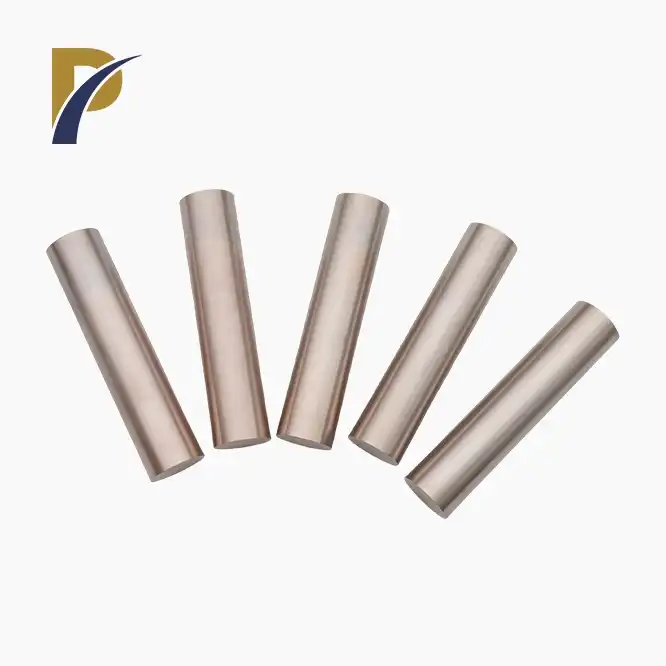

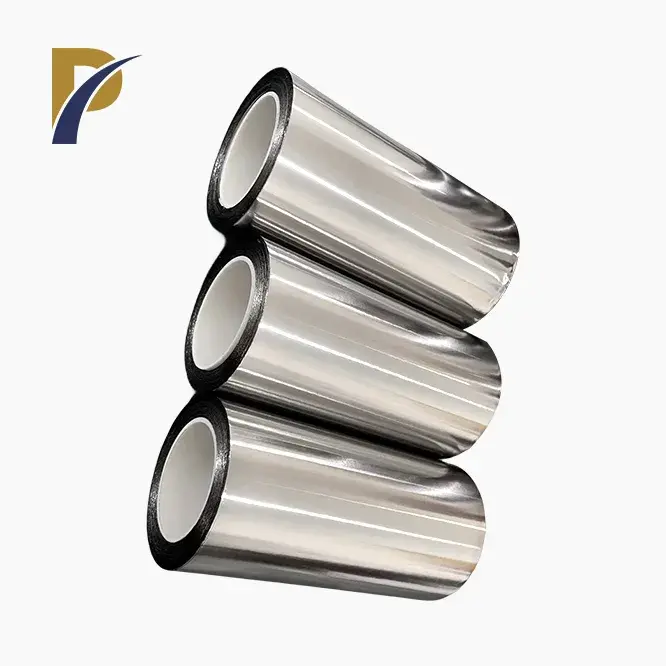

molybdenum tzm alloy

Diameter: 2-200mm

Length: 10-250mm

Density: 10.22g·cm-3

Elongation: 20%

Melting Point : 2617℃

Yield Strength: 560~1150MPa

Tensile Strength: 685MPa

Resistivity: (5.3~5.5)X10-8 Ω·m

Standard: ASTM B387

PRODUCT DESCRIPTION

Product Introduction

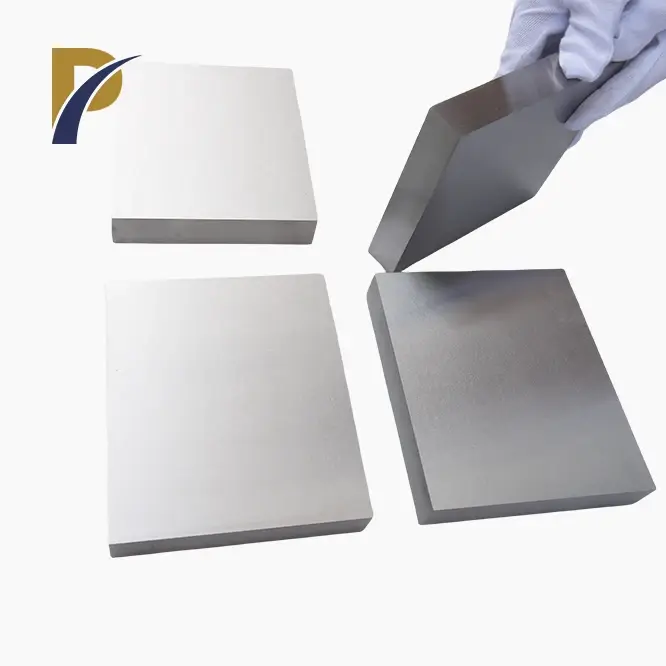

Molybdenum TZM alloy (Titanium-Zirconium-Molybdenum) is a high-strength, high-temperature alloy known for its excellent mechanical properties and resistance to thermal stress. This alloy is commonly used in industries requiring materials that can withstand extreme temperatures, such as aerospace, automotive, and power generation. With the incorporation of small amounts of titanium and zirconium, TZM alloy enhances the high-temperature creep strength, hardness, and resistance to oxidation.

Shaanxi Peakrise Metal Co., Ltd. is a trusted supplier of molybdenum TZM alloy, serving global markets with top-quality non-ferrous metal products. With over a decade of experience, we have built a strong reputation for delivering reliable and high-performance materials to industries worldwide. Our molybdenum TZM alloy is produced using advanced manufacturing processes, ensuring consistent quality and compliance with international standards. We are committed to providing the best materials to meet the specific needs of our customers.

|

|

|

|

|

|

Product Parameters Table

| Property | Value | Unit |

|---|---|---|

| Density | 10.22 | g/cm³ |

| Melting Point | 2620 | °C |

| Tensile Strength | 690 | MPa |

| Elongation | 20 | % |

| Thermal Conductivity | 140 | W/m·K |

| Coefficient of Expansion | 5.9 x 10⁻⁶ | /K |

| Element Composition | Percentage | Unit |

|---|---|---|

| Molybdenum (Mo) | 99 | % |

| Titanium (Ti) | 0.50 | % |

| Zirconium (Zr) | 0.08 | % |

| Carbon (C) | 0.02 | % |

Physical and Mechanical Properties

Molybdenum TZM alloy offers a range of physical and mechanical properties, making it suitable for high-stress applications:

- High Strength at Elevated Temperatures: TZM alloy retains its mechanical properties even at temperatures exceeding 1400°C, making it ideal for aerospace and energy industries.

- Creep Resistance: The alloy exhibits excellent resistance to creep deformation at high temperatures, ensuring long-lasting performance.

- Oxidation Resistance: Its resistance to oxidation at elevated temperatures reduces material degradation, extending the alloy's service life.

- Thermal Stability: With low thermal expansion and high thermal conductivity, TZM ensures stability in environments with significant temperature changes.

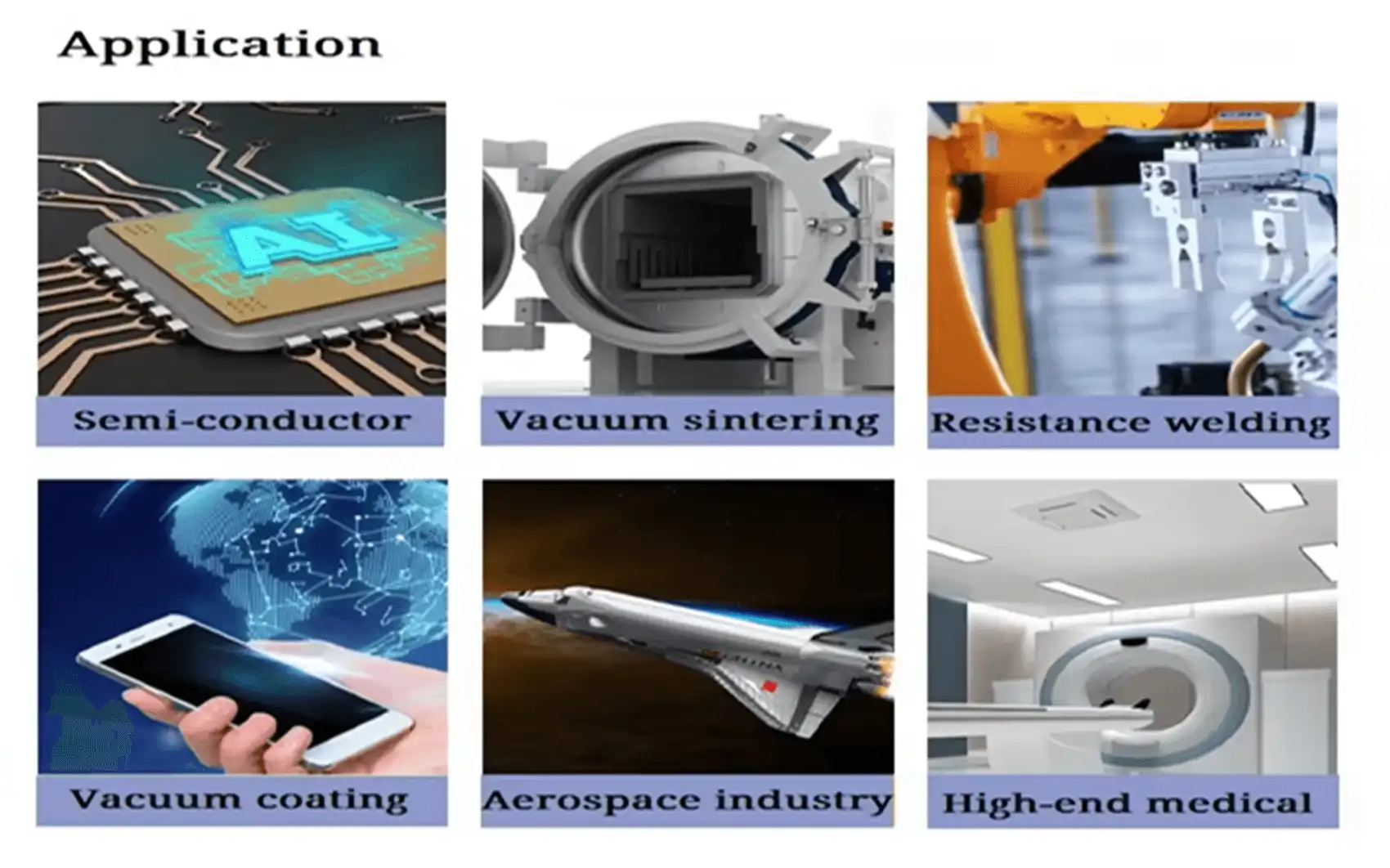

Product Applications

- Aerospace Industry: Used in high-temperature parts such as rocket nozzles, turbine blades, and thrust chambers, where durability and resistance to thermal stress are crucial.

- Power Generation: Essential in the production of heat exchangers, nuclear reactors, and power plant components that operate under extreme heat.

- Automotive Industry: TZM alloy is used in the manufacturing of components for internal combustion engines and other high-temperature machinery.

- Furnace Equipment: Due to its thermal stability, TZM is used in furnace parts, including heating elements and high-performance crucibles.

Product Process and Production Flow

The production of TZM alloy at Shaanxi Peakrise Metal Co., Ltd. follows a rigorous process:

- Material Selection: High-purity molybdenum, titanium, and zirconium are sourced for production.

- Vacuum Arc Melting: The raw materials are melted in a vacuum arc furnace to form a homogeneous alloy.

- Hot Rolling: The alloy is processed through hot rolling to enhance its mechanical properties and ensure uniformity.

- Annealing: To relieve internal stresses and improve machinability, the alloy undergoes a vacuum annealing process.

- Final Machining: The alloy is machined into final shapes as per customer requirements, ensuring precision and quality.

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art facility equipped with cutting-edge technology. Our equipment includes vacuum furnaces, CNC machines, laser cutters, and rolling mills. Our manufacturing capabilities allow us to handle large production volumes while maintaining the highest quality standards. We have a dedicated team of engineers and technicians who ensure that all products meet international specifications.

Logistics and Packaging

Packaging:

Wooden crate packaging

Foam-filled carton packaging

Waterproof and moisture-proof packaging

Custom packaging options available upon request

|

|

|

|

|

|

|

|

-

- Logistics:

- Sea freight for bulk orders

- Air freight for urgent deliveries

- Multimodal transport solutions

- International express courier services

Why Choose Us?

- Expertise: With over ten years of experience, we specialize in the production of high-performance non-ferrous metals.

- Quality Assurance: Our products are manufactured and tested to the highest industry standards, ensuring reliability and durability.

- Advanced Facilities: Our facility is equipped with modern equipment to ensure precise manufacturing and high production efficiency.

- Global Reach: We have established long-term relationships with customers in the United States, Germany, South Korea, and beyond.

- Customer-Centric Approach: We prioritize customer satisfaction by offering customized solutions and excellent after-sales service.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer comprehensive OEM/ODM services. We can customize molybdenum TZM alloy components to meet your specific application needs. From product design to final production, our experienced team works closely with clients to deliver tailored solutions that enhance performance and cost-efficiency.

FAQ

- What is the typical composition of TZM alloy?

- Molybdenum TZM alloy consists of 99% molybdenum, 0.50% titanium, and 0.08% zirconium.

- How does TZM alloy perform at high temperatures?

- TZM alloy maintains its mechanical properties even at temperatures exceeding 1400°C, making it suitable for extreme environments.

- Can the dimensions of TZM alloy products be customized?

- Yes, we provide fully customizable solutions to meet your project requirements, including dimensions and tolerances.

- What industries commonly use TZM alloy?

- TZM alloy is widely used in aerospace, automotive, and power generation industries.

- How is the alloy packaged for shipping?

- We offer wooden, carton, and foam-filled packaging, ensuring products are protected from moisture and damage during transport.

Contact Us

For more information or to place an order, please contact us at info@peakrisemetal.com. We look forward to partnering with you and providing high-quality molybdenum TZM alloy solutions for your specific needs.