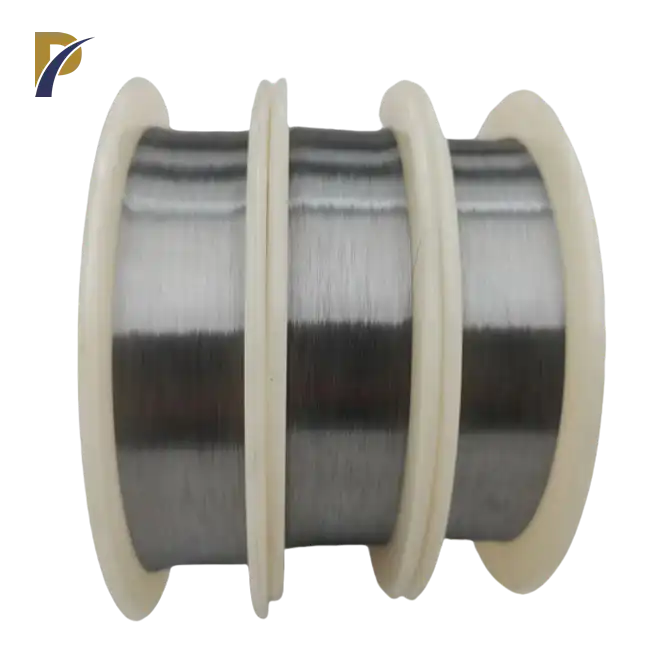

molybdenum alloys wire

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Molybdenum Alloys Wire – Product Introduction

Product Introduction

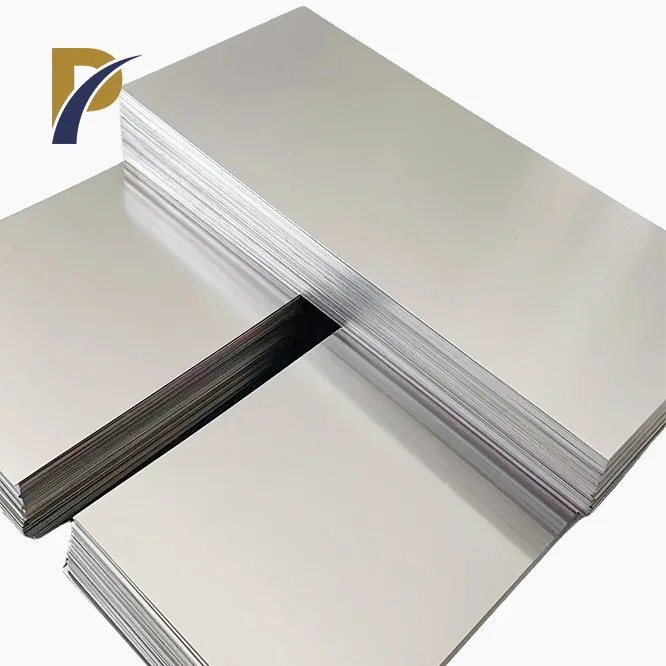

Molybdenum alloys wire represents a pinnacle in high-performance materials, particularly valued in industries demanding superior strength, heat resistance, and electrical conductivity. At Shaanxi Peakrise Metal Co., Ltd., we specialize in producing high-quality molybdenum alloys wire tailored to meet the stringent requirements of various industrial applications. Our molybdenum wire is crafted using state-of-the-art technology and expertise, ensuring unparalleled quality and performance. With extensive experience in the production of tungsten, molybdenum, and other non-ferrous metals, we provide solutions that not only meet but exceed industry standards.

Our molybdenum alloys wire is designed for demanding environments where resistance to high temperatures and corrosion is crucial. We take pride in our rigorous quality control processes and our commitment to delivering products that adhere to international standards. Whether for aerospace, electronics, or other high-tech industries, our molybdenum wire delivers consistent performance, reliability, and durability.

Product Parameters

| Parameter | Specification |

|---|---|

| Material | Molybdenum Alloy |

| Diameter Range | 0.1 mm - 5 mm |

| Tensile Strength | 550 MPa |

| Melting Point | 2,623°C |

| Density | 10.28 g/cm³ |

| Resistivity | 5.2 μΩ·cm |

| Elongation at Break | 2% |

| Parameter | Specification |

|---|---|

| Purity | ≥99.95% |

| Thermal Conductivity | 138 W/m·K |

| Electrical Conductivity | 20.2 x 10^6 S/m |

| Hardness | 80 HV |

| Young's Modulus | 330 GPa |

| Coefficient of Expansion | 5.6 x 10^-6 /K |

| Parameter | Specification |

|---|---|

| Surface Finish | Smooth/Polished |

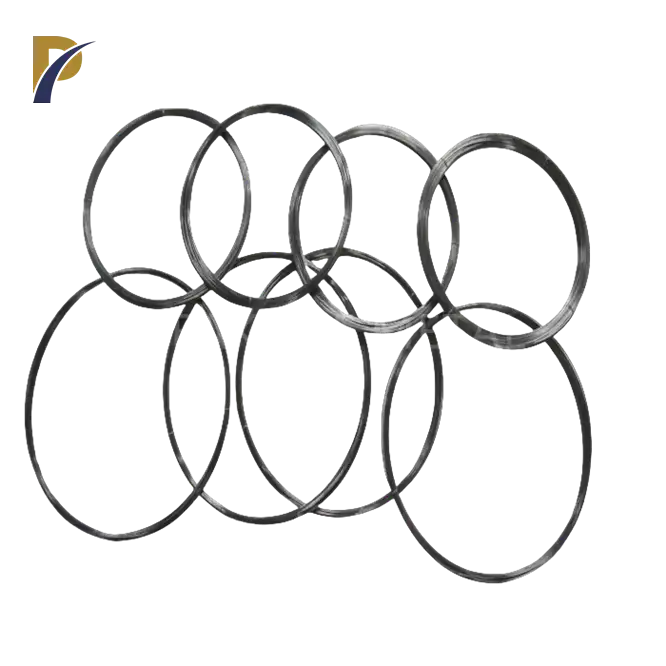

| Form | Straight Wire, Coil |

| Standard | ASTM B386 |

| Packaging | Reel, Custom Box |

| Lead Time | 2-4 Weeks |

|

|

|

Physical and Chemical Properties

Molybdenum alloys wire exhibits remarkable physical and chemical properties that make it an ideal choice for high-performance applications. Key properties include:

- High Melting Point: Molybdenum's melting point of 2,623°C ensures stability and performance in extreme temperatures.

- Excellent Thermal Conductivity: With a thermal conductivity of 138 W/m·K, it effectively dissipates heat.

- Superior Electrical Conductivity: Molybdenum wire offers low electrical resistivity, making it suitable for various electrical and electronic applications.

- Corrosion Resistance: Molybdenum alloys are highly resistant to oxidation and corrosion, enhancing durability and longevity.

|

|

Product Applications

- Aerospace Industry: Used in components that operate at high temperatures and require high strength and resistance to wear.

- Electronics: Ideal for electrical contacts, filaments, and other components requiring high conductivity and durability.

- Industrial Heating: Utilized in high-temperature heating elements due to its excellent thermal and electrical properties.

- Metallurgical Applications: Employed in processes involving high temperatures and aggressive environments.

|

|

Manufacturing Process and Production Flow

- Material Selection: High-purity molybdenum is selected as the raw material.

- Melting and Alloying: Molybdenum is melted and alloyed to achieve desired properties.

- Drawing: The alloy is drawn into wire of specified diameters.

- Annealing: The wire undergoes annealing to enhance ductility and strength.

- Quality Control: Rigorous testing ensures compliance with standards and specifications.

- Packaging: The final product is carefully packaged to prevent damage during transit.

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer of non-ferrous metals with extensive experience in producing tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel alloys. Our facility is equipped with advanced technology and adheres to strict quality control measures to ensure the highest standards of production. Our commitment to innovation and customer satisfaction drives our success in delivering top-tier metal products to global markets.

Logistics and Packaging

Our molybdenum alloys wire is packaged securely to prevent damage during transportation. Packaging options include reels and custom boxes, tailored to meet specific customer requirements. We offer reliable logistics solutions to ensure timely delivery to international destinations.

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: Extensive experience in the production of high-quality non-ferrous metals.

- Advanced Technology: Utilization of state-of-the-art manufacturing processes.

- Quality Assurance: Rigorous quality control to ensure product excellence.

- Global Reach: Reliable logistics and distribution capabilities.

- Customer Focus: Commitment to meeting specific customer needs and requirements.

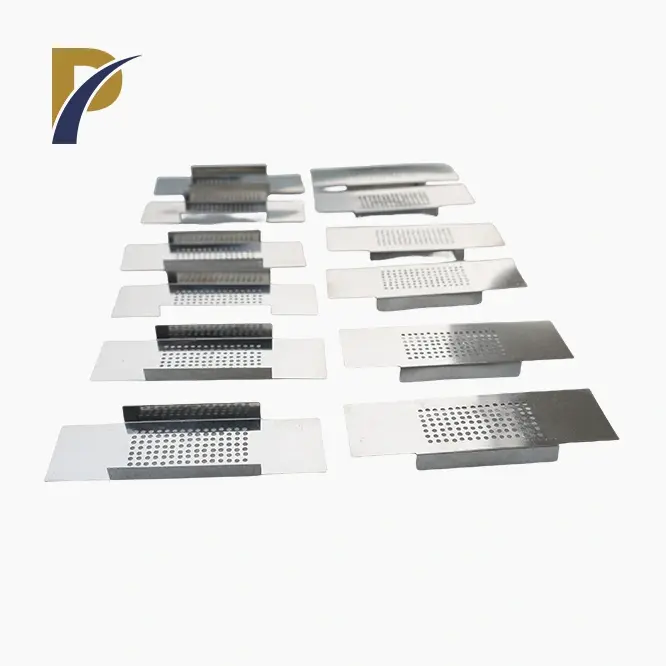

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers customized processing services to meet your unique specifications. Whether you require specific dimensions, packaging, or other customizations, our OEM services are designed to accommodate your needs and ensure optimal product performance.

|

|

|

|

|

|

|

|

|

Frequently Asked Questions (FAQ)

-

What is the typical lead time for molybdenum alloys wire?

- Lead time is generally 2-4 weeks, depending on order size and specifications.

-

Can you provide samples of the molybdenum wire?

- Yes, samples can be provided upon request.

-

What are the packaging options available?

- Packaging options include reels and custom boxes, tailored to your needs.

-

Do you offer custom sizes and specifications?

- Yes, we offer OEM services to accommodate specific size and specification requirements.

Call to Action (CTA)

Contact us info@peakrisemetal.com today to learn more about our high-quality molybdenum alloys wire and how it can benefit your applications. Reach out to our team for a quote or to discuss your specific needs.

_1735890013155.webp)