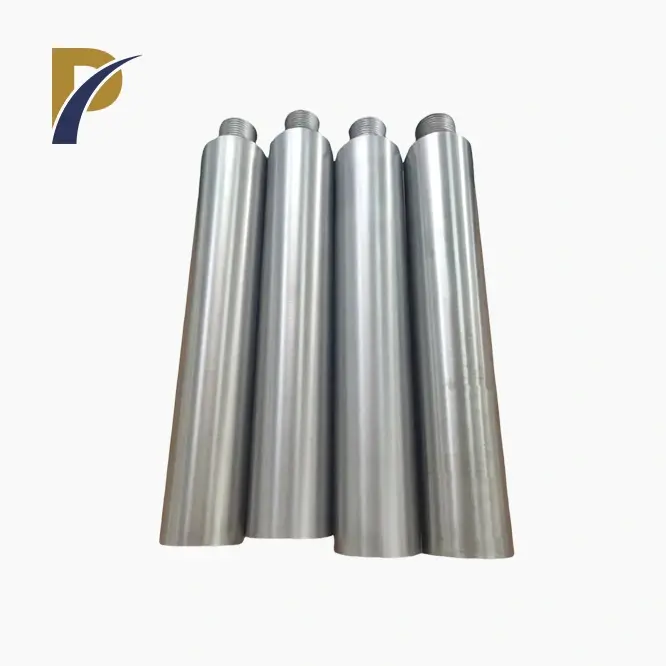

smooth molybdenum crucible

Purity: 99.95%

Density: 10.2g/cm3

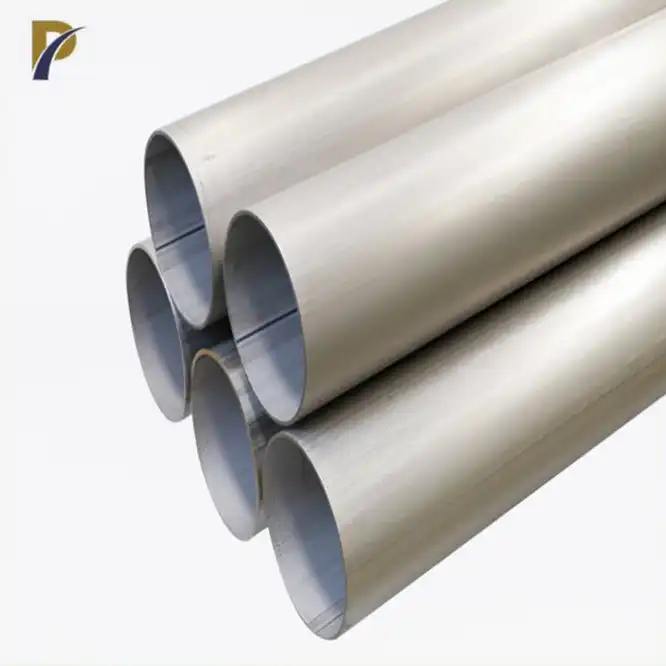

Shape: Crucible

Diameter: Max.450mm

Height: Max.800mm

Finish: Ra<1.6

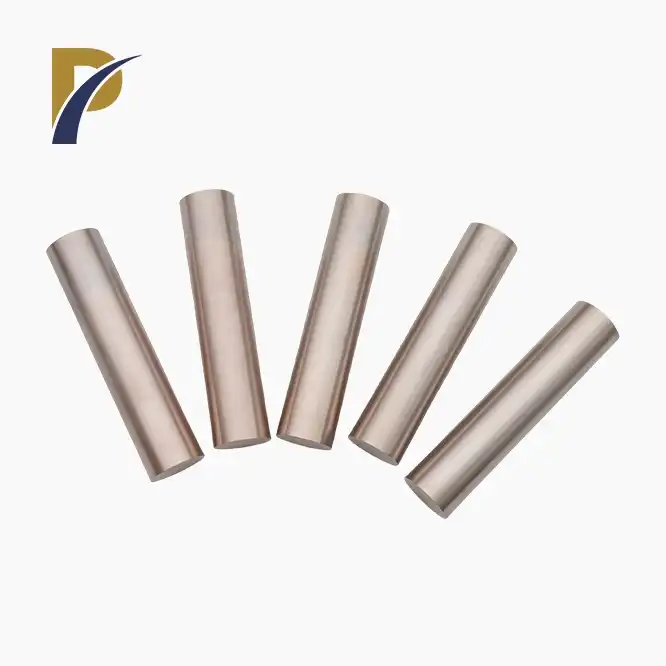

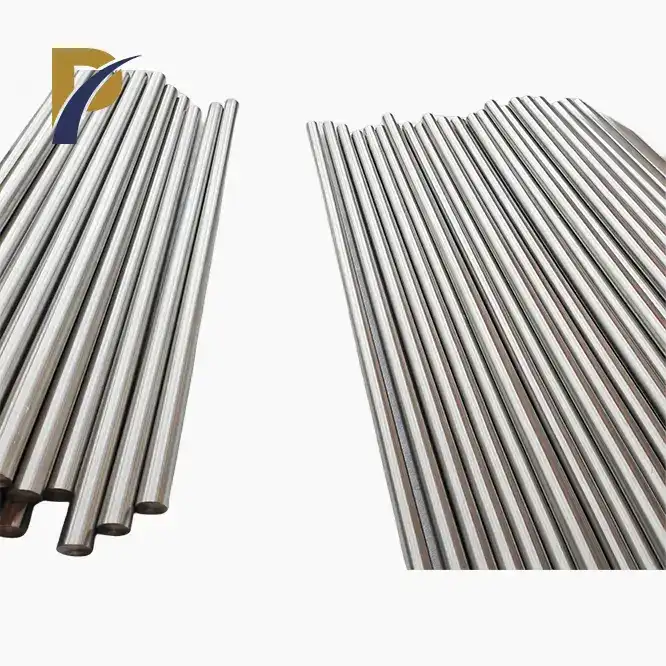

Craft: Sintering,Machined

Application: Metallurgical industry, rare earth industry, monocrystalline silicon, solar energy, artificial crystal and mechanical processing industries.

PRODUCT DESCRIPTION

Smooth Molybdenum Crucible: Product Introduction Page for Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Smooth molybdenum crucibles are essential in industries where high-temperature processes require materials that can withstand extreme conditions. These crucibles, made from high-purity molybdenum, offer excellent heat resistance, high melting points, and superb corrosion resistance, making them suitable for a wide range of applications, including crystal growth, glass melting, and metal casting. Molybdenum crucibles are critical in aerospace, electronics, and energy industries due to their remarkable physical properties.

At Shaanxi Peakrise Metal Co., Ltd., we are proud suppliers of top-quality smooth molybdenum crucibles. With over a decade of experience in producing non-ferrous metal products, we provide a comprehensive range of molybdenum and related metal products to global customers. Our molybdenum crucibles are designed with precision and undergo rigorous quality control to meet the highest industry standards. Whether for research, industrial, or production applications, our crucibles are known for their durability, reliability, and performance in high-temperature environments.

Product Parameters Table

We ensure accuracy in all technical data for our molybdenum crucibles, enabling users to select the right product for their specific needs. Below are three sets of non-repetitive parameters tables highlighting different aspects of our smooth molybdenum crucibles.

Table 1: Basic Dimensions

| Type | Size(mm) | Tolerance(mm) | ||

| Diameter (mm) | Height (mm) | Diameter(mm) | Height(mm) | |

| Sintered Mo crucible | 10-500 | 10-600 | ±5 | ±5 |

| Forged Mo crucible | 10-130 | 10-200 | ±1 | ±2 |

| Sintering and Machined | 100-450 | 10-500 | ±0.5 | ±1 |

Table 2: Physical Properties

| Property | Value |

|---|---|

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Boiling Point | 4612°C |

| Electrical Resistivity | 5.34 µΩ·cm at 20°C |

Table 3: Thermal and Mechanical Properties

| Property | Value |

|---|---|

| Thermal Conductivity | 138 W/m·K at 20°C |

| Coefficient of Expansion | 4.8 x 10⁻⁶ /°C |

| Tensile Strength | 690 MPa |

| Hardness | 150 HV |

|

|

|

Physical and Chemical Properties

Molybdenum crucibles exhibit excellent high-temperature resistance and chemical stability. Their smooth surface ensures minimal contamination during high-purity processes. The high melting point of molybdenum (2620°C) enables these crucibles to endure extreme thermal environments without deformation or degradation. Their low thermal expansion minimizes stress during rapid temperature changes, ensuring longer operational life in demanding environments. Additionally, molybdenum’s resistance to most acids and bases makes it an ideal choice for processes involving reactive chemicals.

| Quantitative analysis | ||||||||||

| Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Cu | Ca | P |

| Concentration(%) | 0.0006 | 0.0006 | 0.001 | 0.0006 | 0.003 | 0.0006 | 0.003 | 0.0006 | 0.0006 | 0.001 |

| Element | C | O | Sb | |||||||

| Concentration(%) | 0.001 | 0.005 | 0.0006 | |||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||

Product Functions

- High-Temperature Tolerance: Molybdenum crucibles can withstand temperatures up to 2620°C, making them ideal for processes involving extreme heat, such as metal melting and crystal growth.

- Corrosion Resistance: Their ability to resist corrosion from various chemicals and gases ensures longevity and stability in harsh environments.

- Dimensional Stability: The low thermal expansion rate prevents cracking or warping, ensuring reliable use during rapid heating and cooling cycles.

- Purity Maintenance: The smooth surface of the crucible minimizes contamination, preserving the integrity of materials being processed.

- Energy Efficiency: The high thermal conductivity of molybdenum ensures efficient heat transfer, reducing energy consumption in high-temperature applications.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- Aerospace Industry: Used for metal casting and manufacturing components that require high precision and heat resistance.

- Glass and Crystal Growth: Ideal for sapphire crystal growth and the melting of high-purity glass due to the crucible's ability to withstand high temperatures and prevent contamination.

- Semiconductor Industry: Smooth molybdenum crucibles are employed in vapor deposition processes and the production of semiconductor materials.

- Energy Production: Essential in processes involving nuclear materials or high-temperature power generation.

- Metallurgical Industry: Used for melting and alloying high-purity metals, particularly in producing specialty alloys and superalloys.

|

|

Product Process and Production Flow

Our production process for smooth molybdenum crucibles begins with the selection of high-purity molybdenum powder. The material is then sintered in an intermediate frequency sintering furnace, followed by a precision shaping process using vacuum arc melting furnaces. Throughout production, each step is monitored to maintain the highest quality standards. Final machining is carried out with CNC equipment to ensure exact dimensions and a smooth finish. Each crucible undergoes thorough testing for density, strength, and surface quality before being dispatched to customers.

Logistics and Packaging

- Wooden Crate Packaging: Provides maximum protection during long-distance shipping, particularly for heavy-duty and delicate items.

- Carton Packaging: Suitable for smaller or lighter products, ensuring cost-effective transportation.

- Foam-Filled Packaging: Offers added cushioning to prevent any impact damage.

- Waterproof and Moisture-Proof Packaging: Ensures the product’s integrity during storage and shipping in humid environments.

- Custom Packaging: Tailored solutions to meet specific customer requirements.

|

|

|

|

|

|

|

|

Logistics:

- Sea Freight: Suitable for large, heavy shipments with longer lead times.

- Air Freight: Ideal for urgent shipments, offering a fast turnaround.

- Land Transport: Used for regional deliveries, ensuring timely arrival.

- Multimodal Transport: Combines various transport methods for the most efficient logistics solution.

- Courier Services: Perfect for smaller or high-value shipments requiring expedited delivery.

Why Choose Us?

- Rich Experience: With over ten years in the non-ferrous metal industry, we have established ourselves as experts in producing high-quality molybdenum products.

- Global Reach: Our products are exported to countries such as the United States, Germany, and South Korea, with long-term relationships established with clients worldwide.

- Advanced Production Equipment: We utilize state-of-the-art machinery, including vacuum arc melting furnaces, CNC equipment, and sintering furnaces, ensuring the highest standards of precision and quality.

- Commitment to Quality: We follow ISO 9001 standards, ensuring that every product meets stringent quality control benchmarks.

- Comprehensive OEM/ODM Services: We offer flexible, custom manufacturing solutions to meet specific customer needs.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. is proud to offer OEM and ODM services, allowing clients to customize molybdenum crucibles to their exact specifications. Whether it’s adjusting dimensions, adding features, or producing entirely new designs, we work closely with clients to ensure that all requirements are met. Our R&D team is ready to assist in material selection, product testing, and quality assurance.

|

|

|

|

|

|

|

|

|

FAQ

- What is the purity of your molybdenum crucibles?

- Our crucibles have a minimum purity of 99.95%, ensuring optimal performance in high-temperature applications.

- Can I customize the dimensions of the crucibles?

- Yes, we offer full customization services for our crucibles to meet specific client requirements.

- What is the maximum operating temperature for your molybdenum crucibles?

- Our molybdenum crucibles can operate at temperatures up to 2620°C.

- What industries commonly use your crucibles?

- Our crucibles are widely used in the aerospace, semiconductor, and glass industries.

- How do you ensure the quality of your products?

- We follow ISO 9001 quality assurance standards and perform rigorous testing throughout the production process.

Contact Us

For more information or to place an order for our smooth molybdenum crucibles, contact us today. Our team at Shaanxi Peakrise Metal Co., Ltd. is ready to assist you with any inquiries. Reach out to us via info@peakrisemetal.com for high-quality products, reliable service, and competitive pricing.