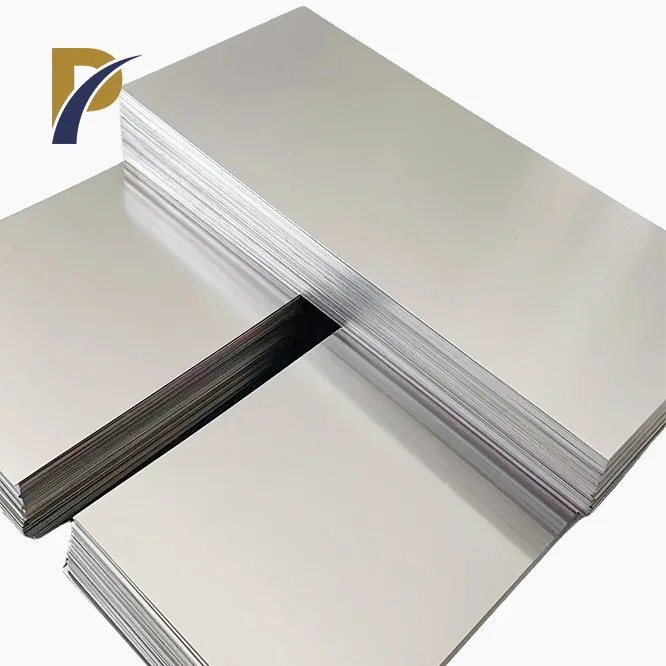

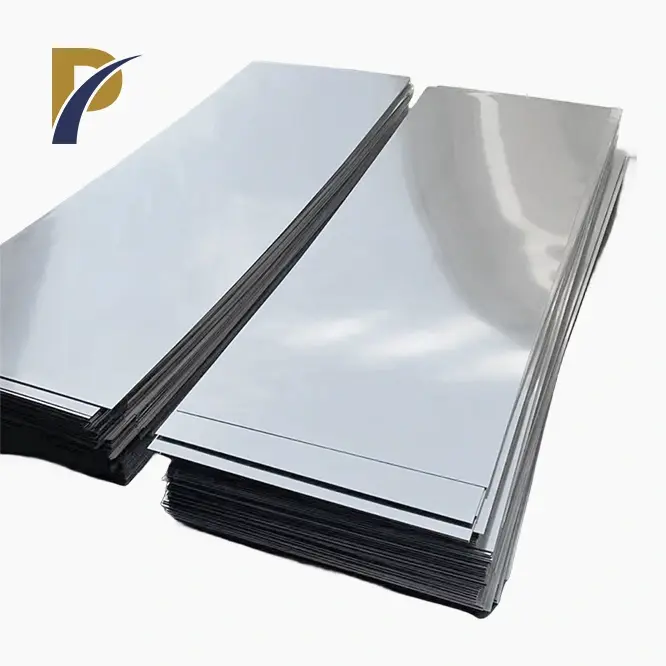

High purity 99.97% molybdenum plates

W Content: 50% (wt%)

Mo Content: 50% (wt%)

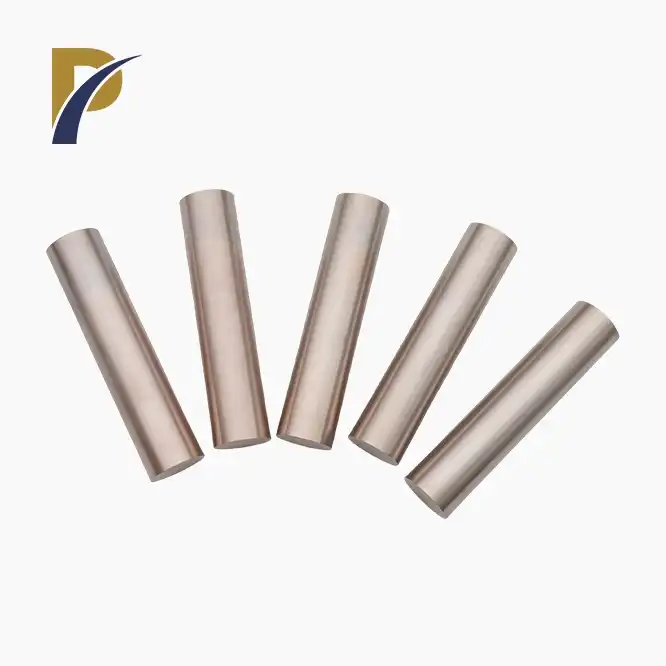

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction: High purity 99.97% molybdenum plates

High purity 99.97% molybdenum plates are highly regarded in the non-ferrous metals industry for their superior thermal conductivity, electrical properties, and excellent performance in harsh environments. As a key material for electronic components, high-temperature furnaces, and various high-performance applications, these plates are essential in industries such as aerospace, electronics, and medical devices.

Shaanxi Peakrise Metal Co., Ltd. is a leading global supplier of High purity 99.97% molybdenum plates. With extensive experience in the production of high-quality non-ferrous metals, including molybdenum, tungsten, tantalum, niobium, titanium, and more, we are proud to offer a product that meets the highest industry standards. Our presensitized molybdenum plates are known for their durability, precision, and adaptability to a wide range of applications, ensuring reliable performance in even the most demanding conditions.

With over a decade of experience in exporting molybdenum products, Shaanxi Peakrise Metal Co., Ltd. has established a strong reputation for delivering excellence across global markets. Our plates are manufactured with precision and undergo rigorous quality testing, ensuring that our clients receive only the best materials. This dedication to quality has made us a trusted partner for businesses in the United States, Germany, South Korea, and beyond.

Product Parameters Table

| Product Name | Molybdenum plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tensile strength | 610 Mpa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Elongation | ≥10% | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity | ≥99.95%,≥99.97%, | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Size | TK 0.1~80mm*W 10~700mm*L 30~3000mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Use temperature | 1800°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Highest temperature | 2200°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quantitative analysis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Cd | Ca | P | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | N | Sb | Sn | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

Physical and Mechanical Properties

- Thermal Conductivity: Molybdenum exhibits excellent thermal conductivity, making it ideal for high-temperature environments and heat management in electronic devices.

- High Melting Point: With a melting point of 2,623°C, molybdenum plates can withstand extreme temperatures without deformation.

- Low Thermal Expansion: The low coefficient of thermal expansion ensures stability in applications requiring precision over temperature fluctuations.

- Corrosion Resistance: Presensitized molybdenum plates are resistant to oxidation and corrosion, providing longevity in challenging industrial environments.

- High Strength: These plates exhibit remarkable mechanical strength, maintaining structural integrity under heavy loads.

Product Applications

- Electronics: Used in heat sinks, semiconductor substrates, and circuit boards where efficient heat management is critical.

- Aerospace: Applied in components requiring high-temperature resistance, such as turbine blades and aerospace fasteners.

- Medical Devices: Molybdenum’s biocompatibility and strength make it suitable for use in medical implants and diagnostic equipment.

- High-Temperature Furnaces: Withstanding extreme heat, molybdenum plates are ideal for furnace components in metalworking and material processing industries.

- Nuclear Power: The radiation shielding properties of molybdenum make it a reliable material for use in nuclear reactors and related technologies.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM and ODM services for presensitized molybdenum plates. We can customize products to meet your specific needs, including thickness, dimensions, and surface finishes. Our advanced production facilities and skilled engineering team are equipped to handle complex customization requests, ensuring that you receive a product tailored to your unique applications.

|

|

|

|

Why Choose Us?

- Expertise: With over a decade of experience in non-ferrous metals, we understand the specific needs of industries requiring molybdenum plates.

- Advanced Production Equipment: We employ state-of-the-art machinery such as vacuum arc melting furnaces and laser cutters to ensure precision and quality.

- Global Reach: Our products are exported to over 20 countries, including the United States, Germany, and South Korea, with a reputation for reliability.

- Quality Assurance: We adhere to strict quality control processes, including ISO 9001 certification, to ensure our products meet international standards.

- Customization Capability: Our OEM/ODM services provide tailored solutions to meet your specific project requirements.

- Innovative R&D: Our ongoing research and development efforts ensure that we are always at the forefront of material technology.

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

- Wooden crate packaging for large orders and heavy-duty applications.

- Carton packaging for smaller quantities, ensuring protection during transit.

- Foam-filled packaging to prevent damage from impact.

- Waterproof and moisture-proof packaging for added durability.

- Custom packaging available upon request to meet international shipping standards.

|

|

|

|

|

|

|

|

Logistics

- Sea Freight: Economical for large shipments across international borders.

- Air Freight: Fast and efficient for time-sensitive orders.

- Land Transportation: Ideal for regional deliveries within countries.

- Multimodal Transport: Combining sea, air, and land for optimal efficiency.

- Courier Services: Available for smaller shipments requiring rapid delivery.

FAQ

-

What is the lead time for custom molybdenum plates?

Our standard lead time for custom orders is 3-4 weeks, depending on the complexity of the request. -

Can you provide certification for the material used?

Yes, we provide material certifications, including purity and composition analysis. -

What is the maximum thickness you can produce?

We can produce molybdenum plates up to 50 mm in thickness. -

Do you ship internationally?

Yes, we ship to over 20 countries worldwide, including the United States and Europe. -

Can I request a sample before placing a large order?

Yes, samples are available upon request for product evaluation.

Contact Us

For more information or to place an order, please contact us at info@peakrisemetal.com. We look forward to partnering with you on your next project and providing high-quality presensitized molybdenum plates to meet your needs.

This content is designed to be easily readable, using straightforward language and mimicking natural human writing habits while maintaining a professional tone suitable for global markets.

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes

VIEW MOREmolybdenum electrodes -

VIEW MOREmolybdenum riveted boat

VIEW MOREmolybdenum riveted boat -

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREsilicon molybdenum rods heating element

VIEW MOREsilicon molybdenum rods heating element -

VIEW MOREpure tungsten electrode

VIEW MOREpure tungsten electrode -

VIEW MOREtungsten copper alloy rod

VIEW MOREtungsten copper alloy rod -

VIEW MOREhigh temperature furnace tungsten crucible

VIEW MOREhigh temperature furnace tungsten crucible