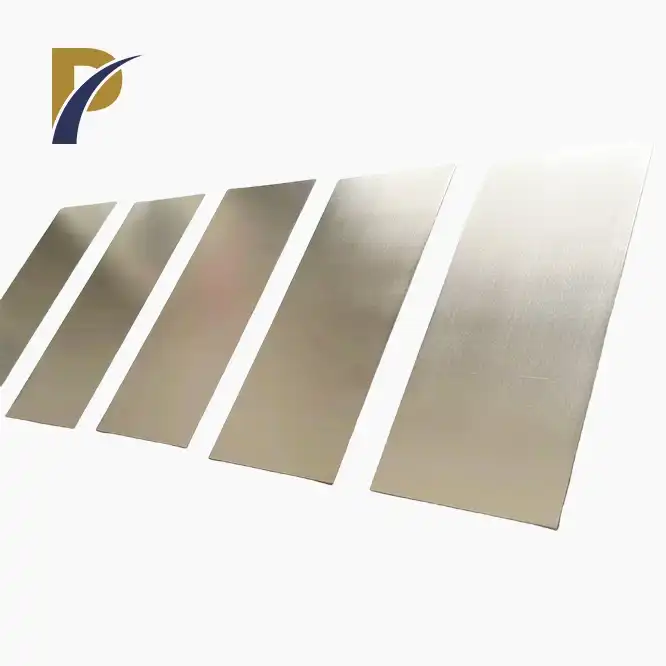

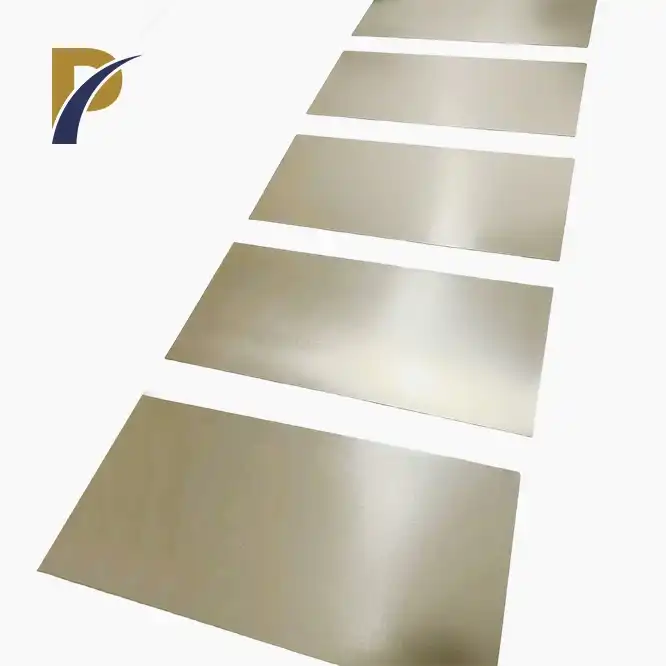

molybdenum sheet plate 0.5mm

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Molybdenum Sheet Plate 0.5mm Product Introduction

Molybdenum sheet plates have become essential components in industries requiring high-temperature resistance, thermal conductivity, and low thermal expansion. The molybdenum sheet plate 0.51, specifically, is widely used for its outstanding mechanical and physical properties. As a leading supplier, Shaanxi Peakrise Metal Co., Ltd. has been providing high-quality molybdenum sheet plates to meet the growing demands of various industries globally. Our molybdenum sheet plate 0.51 is highly durable and resistant to corrosion, making it a reliable choice for applications that require precision and longevity.

For over a decade, we have focused on developing and supplying high-purity molybdenum sheets, supported by advanced research and manufacturing techniques. Our products are exported worldwide, and we are known for providing products that exceed industry standards in quality, consistency, and performance. Molybdenum sheet plate 0.51 is essential in aerospace, electronics, and nuclear industries due to its ability to withstand extreme environments, further underscoring its critical role in modern industrial applications.

Product Parameters Table

Molybdenum sheet plate

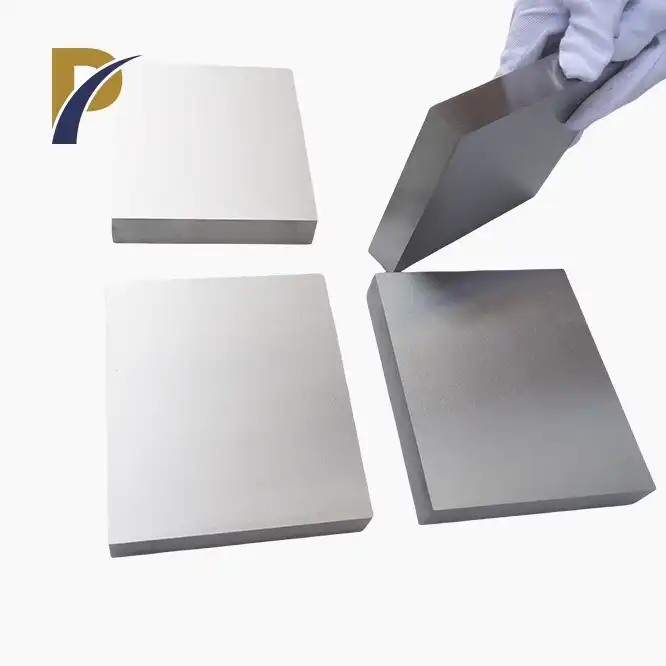

thickness:0.2mm-20mm wideth:10-700mm length:<2500mm

Purity:99.95%,99.97%

Grade:Mo-1,TZM,Mo-La,361,364

Standard:ASTM B386

Surface:black,polished,Alkaline washing,sandblasting

|

|

|

Physical and Mechanical Properties

| Element | Composition % | ||

| Grade | |||

| 361(Mo-1) | 364(TZM) | 366(Mo-30%W) | |

| C | 0.01 max. | 0.01~0.04 | 0.03 max. |

| O,max. | 0.007 | 0.03 | 0.0025 |

| N,max. | 0.002 | 0.002 | 0.002 |

| Fe, max. | 0.01 | 0.01 | 0.01 |

| Ni, max. | 0.005 | 0.005 | 0.005 |

| Si, max. | 0.01 | 0.005 | 0.01 |

| Ti | 0.4~0.55 | ||

| W | 27~33 | ||

| Zr | 0.06~0.12 | ||

| Mo | Remain | Remain | Remain |

| Material type |

Condition

|

Thickness inches(mm) | Tensile Strength B Min, klb/in2 (MPa) | Yield Strength 0.2% Residual Deformation, Min, klb/in2 (mm) | Elongation, min, % (2 inches or 50 mm) | Minimum bending radius |

| 361 | SR | ≤0.001(0.025) | 115(795) | 95(655) | 1 | |

| 364 | SR | 0.01~0.025(0.25~0.635) | 120(830) | 100(690) | 6 | 2t |

| ≥0.025~0.06(0.635~1.5) | 120(830) | 100(690) | 7 | 2t | ||

| ≥0.06~0.09(1.5~2.3) | 100(690) | 100(690) | 9 | |||

| ≥0.09~0.189(2.3~4.75) | 120(830) | 100(690) | 10 | |||

| 3/16~1/2(4.75~12.7) | 120(830) | 100(690) | 10 | |||

| ≥1/2~1(12.7~25.4) | 110(760) | 95(655) | 10 | |||

| ≥1~1-1/2(25.4~38) | 100(690) | 85(585) | 8 | |||

| 364 | RX | ≥3/16~1-1/2(4.75~38) | 75(515) | 45(310) | 10 | |

|

A SR=stress relief; RX=almost completely recrystallized , B Longitudinal and transverse testing between 65°F and 85°F (18°C and 29°C) C t=Material thickness D is limited by transverse rolling, transverse elongation is easy to edge. |

||||||

Product Applications

-

Aerospace Industry: Used in high-temperature environments for rocket nozzles, aircraft parts, and heat shields.

-

Semiconductor Manufacturing: Essential for producing components like heating elements, which require stable electrical conductivity and heat resistance.

-

Nuclear Industry: Molybdenum's stability and radiation resistance make it valuable for reactor components.

-

Electronics: Frequently used in the manufacture of power semiconductors and electrical components due to its electrical conductivity.

-

Furnace Components: Ideal for the production of furnace linings, heat shields, and other components exposed to extreme temperatures.

|

|

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we follow a stringent production process to ensure the highest quality standards. Our process includes:

- Raw Material Selection: We source the highest purity molybdenum.

- Sintering: The material is processed in a high-temperature sintering furnace to achieve optimal density.

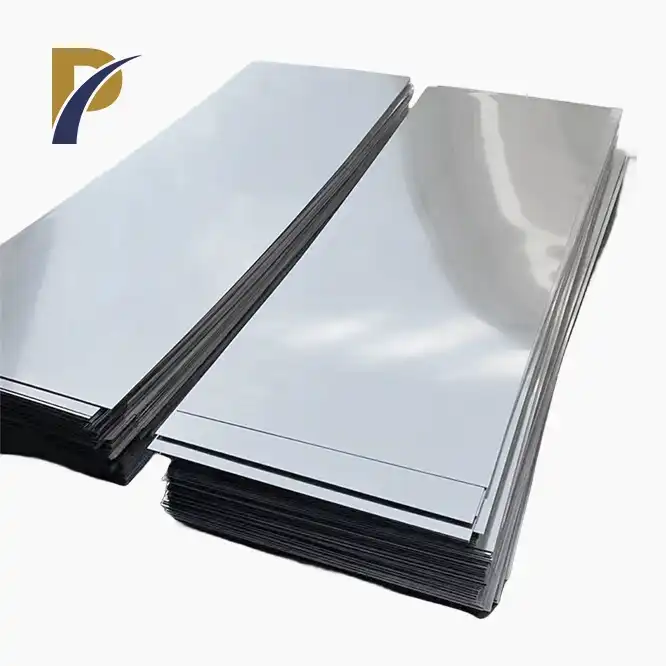

- Rolling and Annealing: The sheets are rolled to the desired thickness, followed by annealing to relieve stresses and enhance material properties.

- Surface Treatment: Final polishing and surface treatments are applied to meet precise specifications.

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a trusted name in the non-ferrous metal production industry. We have an extensive facility equipped with advanced machinery such as intermediate frequency sintering furnaces, vacuum arc melting furnaces, and CNC equipment. Our commitment to quality control, from raw material selection to final product inspection, ensures that our molybdenum sheet plates meet the stringent requirements of global industries.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Packaging: Ideal for bulk shipments and ensures protection during long-distance transport.

- Carton Packaging: For smaller, lighter shipments.

- Foam-filled Packaging: Protects products from impact and ensures moisture resistance.

- Customized Packaging: Available upon request to meet specific needs.

- International Standard Packaging: Ensures compliance with global shipping regulations.

|

|

|

|

|

|

|

|

Why Choose Us?

- Experience: Over a decade of expertise in producing high-quality non-ferrous metal products.

- Global Reach: We export to over 20 countries, including the U.S., Germany, and South Korea.

- Cutting-edge Technology: Advanced production facilities and stringent quality control systems ensure product excellence.

- R&D Capabilities: Our dedicated research and development team continuously innovates to meet evolving industry standards.

- Customer Satisfaction: Our commitment to after-sales service and customer care ensures long-term relationships with global partners.

OEM/ODM Services

We provide comprehensive OEM/ODM services, offering customized solutions to meet specific industry requirements. Whether it’s a unique size, finish, or material specification, Shaanxi Peakrise Metal Co., Ltd. can tailor the molybdenum sheet plate to match your exact needs.

|

|

FAQ

-

What is the purity of your molybdenum sheet plates?

Our molybdenum sheet plates have a purity of ≥99.95%. -

Can you provide custom sizes?

Yes, we offer custom dimensions based on client specifications. -

What is the typical lead time for orders?

The lead time depends on the order size and complexity, but it generally ranges from 3 to 5 weeks. -

Do you provide samples for testing?

Yes, we can provide samples to potential clients for quality verification. -

What industries commonly use your products?

Our molybdenum sheet plates are used in aerospace, nuclear, electronics, and industrial furnace applications.

Contact Us

For further inquiries and to discuss your molybdenum sheet plate 0.51 needs, please contact us. Shaanxi Peakrise Metal Co., Ltd. is here to support global customers with high-quality non-ferrous metal products and solutions. Reach out to us at info@peakrisemetal.com, and we will be happy to assist you.

This detailed product page, featuring molybdenum sheet plate 0.51, aims to provide global customers with accurate and comprehensive information, helping them make informed purchasing decisions.