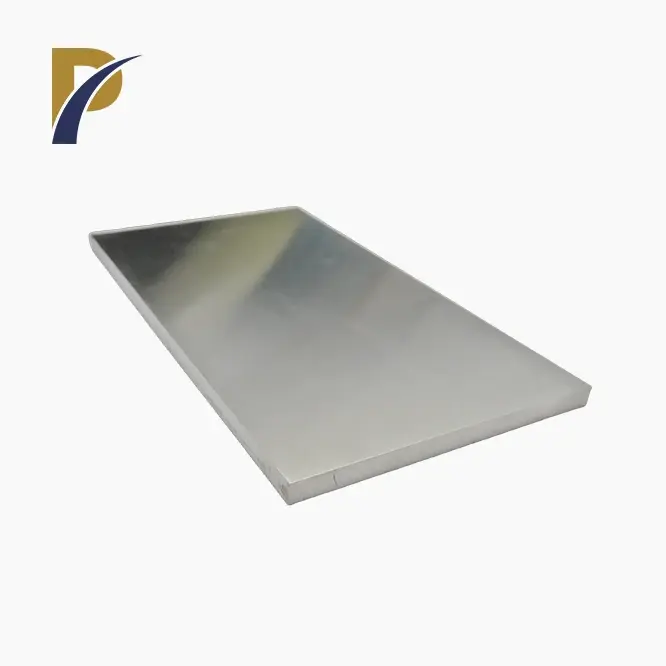

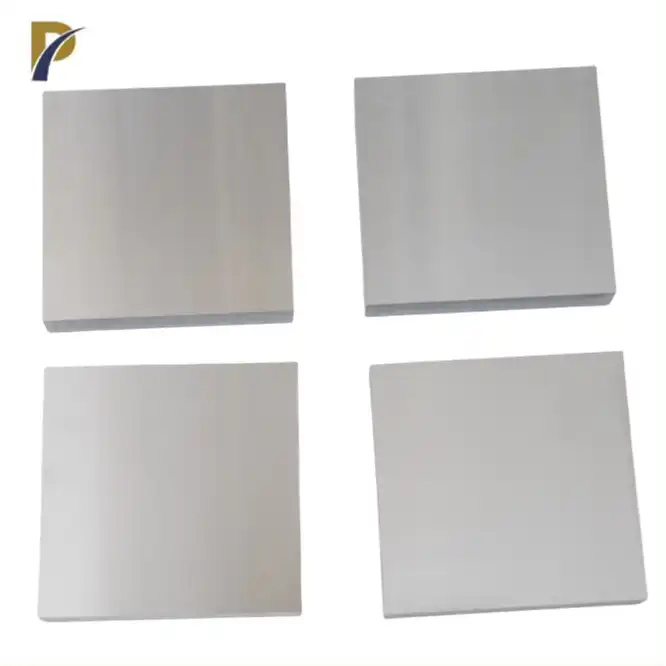

molybdenum plate 0.5 inch

W Content: 50% (wt%)

Mo Content: 50% (wt%)

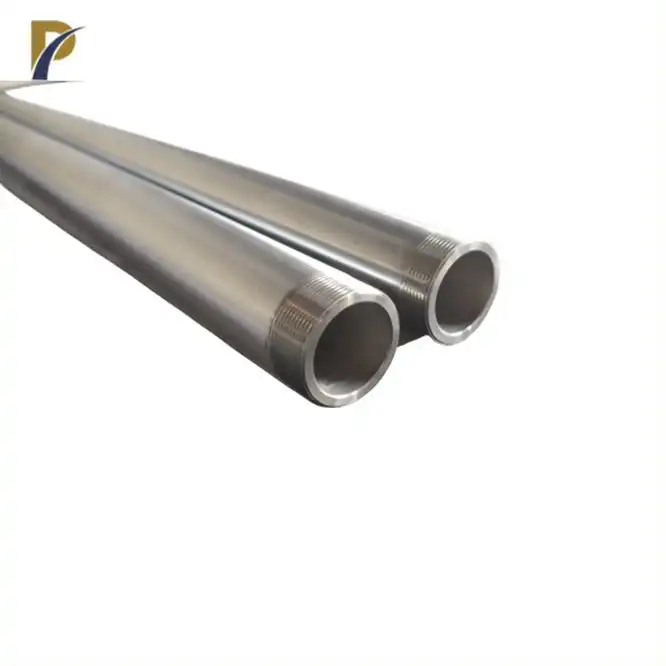

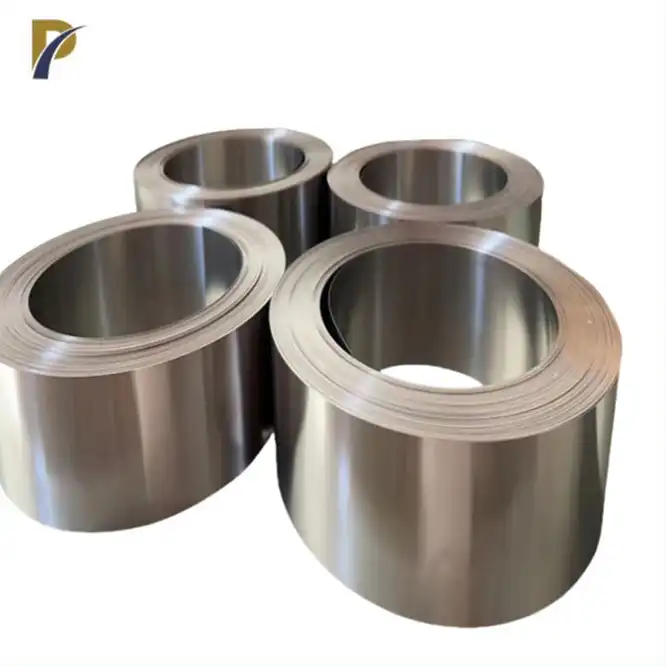

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Molybdenum Plate 0.5 Inch Product Introduction

Molybdenum plates are essential materials in various high-temperature and high-pressure applications due to their outstanding physical and chemical properties. Specifically, the 0.5-inch molybdenum plate produced by Shaanxi Peakrise Metal Co., Ltd. is widely recognized for its exceptional performance in industries such as aerospace, defense, electronics, and manufacturing. The plate is known for its high melting point, excellent thermal and electrical conductivity, and significant resistance to corrosion and wear, making it ideal for demanding environments.

As a leading supplier, Shaanxi Peakrise Metal Co., Ltd. has vast experience in producing and exporting molybdenum plates to global markets. Our dedication to quality and innovation has made us a preferred supplier for industries requiring non-ferrous metals such as tungsten, molybdenum, tantalum, and niobium. With a robust production capacity and comprehensive inventory, we ensure that our customers receive top-tier products promptly, backed by exceptional customer service.

Product Parameters Table

| Parameter | Value |

|---|---|

| Thickness | 0.5 inch |

| Density | 10.22 g/cm³ |

| Melting Point | 2623°C |

| Purity | ≥99.95% |

| Surface Finish | Polished or matte |

| Tensile Strength | 650 MPa |

| Thermal Conductivity | 138 W/m·K |

| Electrical Resistivity | 5.34 µΩ·cm |

| Element | Composition % | ||

| Grade | |||

| 361(Mo-1) | 364(TZM) | 366(Mo-30%W) | |

| C | 0.01 max. | 0.01~0.04 | 0.03 max. |

| O,max. | 0.007 | 0.03 | 0.0025 |

| N,max. | 0.002 | 0.002 | 0.002 |

| Fe, max. | 0.01 | 0.01 | 0.01 |

| Ni, max. | 0.005 | 0.005 | 0.005 |

| Si, max. | 0.01 | 0.005 | 0.01 |

| Ti | 0.4~0.55 | ||

| W | 27~33 | ||

| Zr | 0.06~0.12 | ||

| Mo | Remain | Remain | Remain |

Physical and Mechanical Properties

Performance requirements as per ASTM B386:

| Material type |

Condition

|

Thickness inches(mm) | Tensile Strength B Min, klb/in2 (MPa) | Yield Strength 0.2% Residual Deformation, Min, klb/in2 (mm) | Elongation, min, % (2 inches or 50 mm) | Minimum bending radius |

| 361 | SR | ≤0.001(0.025) | 115(795) | 95(655) | 1 | |

| 364 | SR | 0.01~0.025(0.25~0.635) | 120(830) | 100(690) | 6 | 2t |

| ≥0.025~0.06(0.635~1.5) | 120(830) | 100(690) | 7 | 2t | ||

| ≥0.06~0.09(1.5~2.3) | 100(690) | 100(690) | 9 | |||

| ≥0.09~0.189(2.3~4.75) | 120(830) | 100(690) | 10 | |||

| 3/16~1/2(4.75~12.7) | 120(830) | 100(690) | 10 | |||

| ≥1/2~1(12.7~25.4) | 110(760) | 95(655) | 10 | |||

| ≥1~1-1/2(25.4~38) | 100(690) | 85(585) | 8 | |||

| 364 | RX | ≥3/16~1-1/2(4.75~38) | 75(515) | 45(310) | 10 | |

|

A SR=stress relief; RX=almost completely recrystallized , B Longitudinal and transverse testing between 65°F and 85°F (18°C and 29°C) C t=Material thickness D is limited by transverse rolling, transverse elongation is easy to edge |

||||||

|

|

|

|

Product Functions

- High-Temperature Stability: The molybdenum plate can maintain its structural integrity at temperatures exceeding 2000°C, making it suitable for furnace components, heat shields, and refractory materials.

- Corrosion Resistance: The plate's resistance to oxidation and corrosion ensures long-term durability, particularly in chemical processing industries.

- Superior Conductivity: With its high thermal and electrical conductivity, this plate is used in electronic components such as semiconductor heat sinks and radiation shielding.

- Mechanical Strength: The high tensile strength of molybdenum plates makes them ideal for structural components that require both strength and resistance to high temperatures.

Product Applications

- Aerospace Industry: Molybdenum plates are used in aerospace engines and structural components due to their ability to withstand high temperatures and mechanical stresses.

- Semiconductor Manufacturing: The high thermal conductivity and purity of molybdenum plates make them essential in the semiconductor industry for heat dissipation and protective shielding.

- Nuclear Power: Molybdenum’s resistance to radiation and high-temperature stability makes it a valuable material in nuclear reactors and other radiation-intensive applications.

- Medical Devices: Molybdenum is widely used in medical imaging devices like X-ray equipment, where it helps improve image quality through its superior absorption properties.

- Defense: Due to its exceptional strength-to-weight ratio and high melting point, molybdenum plates are employed in military-grade equipment and armor plating.

|

|

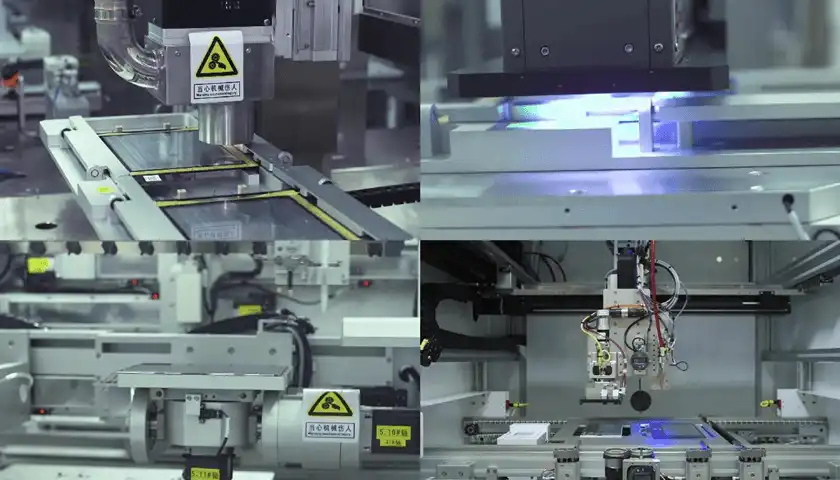

Product Process and Production Flow

Shaanxi Peakrise Metal Co., Ltd. follows stringent manufacturing processes to ensure the highest quality molybdenum plates. Our process includes:

- Powder Metallurgy: Molybdenum powder is compacted and sintered to achieve a dense structure.

- Rolling and Annealing: The sintered molybdenum is rolled into plates and annealed to reduce internal stresses and improve ductility.

- Surface Finishing: After rolling, the plates undergo polishing or other surface treatments to meet customer specifications.

- Quality Control: Each molybdenum plate is rigorously tested for mechanical and chemical properties to ensure it meets international quality standards.

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a highly experienced manufacturer of non-ferrous metals with state-of-the-art production facilities. Our factory is equipped with intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, and various other advanced equipment. With nearly a decade of experience in metal production and processing, we have become a leading supplier in the global market, serving clients in over 30 countries.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Packaging: Strong and durable, ensuring safety during transportation.

- Carton Packaging: Lightweight and cost-effective for smaller orders.

- Foam-Filled Packaging: Provides additional protection for delicate products.

- Waterproof and Moisture-Proof Packaging: Suitable for long-term storage and international shipping.

- Customized Packaging: Available to meet specific customer needs.

- International Standard Packaging: Complies with global shipping regulations.

Logistics Options

- Sea Freight: Cost-effective for bulk shipments, offering global reach.

- Air Freight: Fast and reliable for urgent deliveries.

- Land Transport: Ideal for domestic or neighboring countries.

- Multimodal Transport: Combining various transportation methods for optimized delivery.

- Courier Services: Suitable for smaller, high-value orders requiring rapid delivery.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Extensive Experience: With over a decade of expertise in non-ferrous metals, we provide unmatched quality and service.

- Comprehensive Product Range: We offer a wide range of metal products including tungsten, molybdenum, tantalum, and more, ensuring we meet diverse industry needs.

- Advanced Manufacturing: Our factory is equipped with cutting-edge technology and machinery, ensuring precision and quality in every product.

- Global Reach: We export to over 30 countries, building strong relationships with clients around the world.

- Customer-Centric Approach: We prioritize customer satisfaction, offering customized solutions and exceptional after-sales service.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers customized OEM and ODM services, allowing customers to tailor products according to specific needs. Whether it’s size, shape, or surface finish, we can manufacture molybdenum plates to exact specifications.

|

|

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity for molybdenum plates?

- Our minimum order quantity is flexible, depending on your specific requirements. Please contact us for details.

-

Can you provide custom sizes for molybdenum plates?

- Yes, we offer custom dimensions to meet your project needs.

-

What is the lead time for molybdenum plates?

- Lead times depend on the order quantity and customization requirements, but we strive to fulfill orders within 2-4 weeks.

-

Do you provide samples?

- Yes, we offer samples for testing and evaluation purposes.

-

What certifications do your products have?

- Our products are ISO 9001 certified, ensuring top-quality standards in manufacturing and quality control.

Contact Us

Ready to take your project to the next level with our high-quality molybdenum plates? Contact us at info@peakrisemetal.com to discuss your requirements and get a personalized quote. We look forward to working with you!

_1734665606076.webp)

_1734665606175.webp)

_1734665606149.webp)