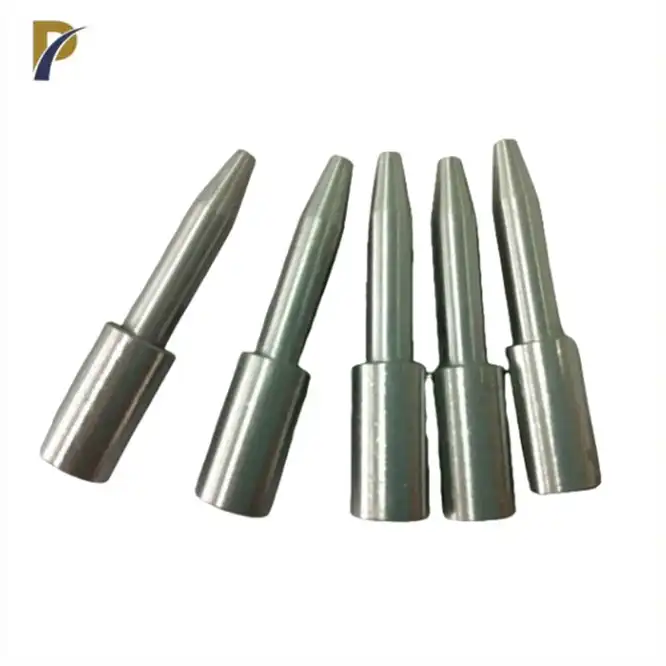

molybdenum welding electrodes

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

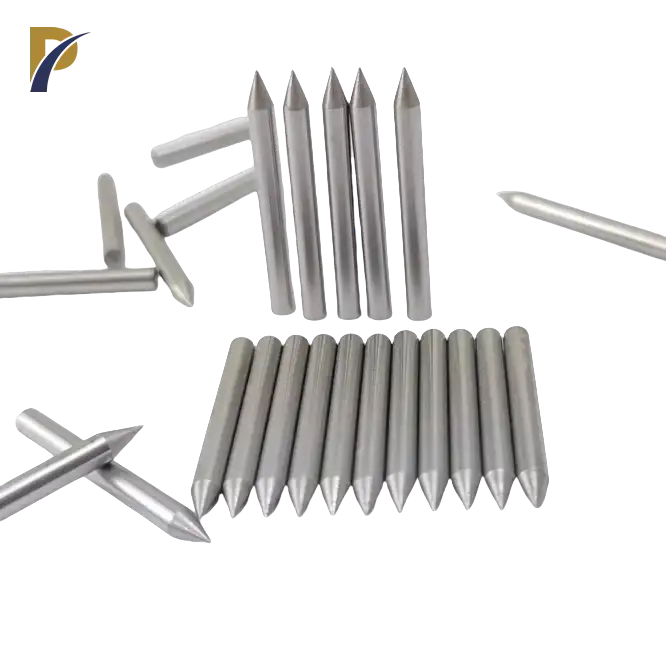

Molybdenum Welding Electrodes – Product Introduction

Molybdenum welding electrodes play a crucial role in a wide range of industries, thanks to their exceptional properties, such as high melting points, excellent thermal conductivity, and resistance to corrosion. These electrodes are commonly used in critical applications that demand reliability under extreme conditions, including aerospace, power generation, and chemical processing.

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of molybdenum welding electrodes, recognized for delivering high-quality products to global markets. With a decade of experience in the production and export of non-ferrous metals, we provide molybdenum electrodes tailored to meet the stringent requirements of our clients. Our electrodes exhibit superior durability, weldability, and conductivity, ensuring efficiency and performance in demanding environments. We take pride in our ability to manufacture products that meet international standards, ensuring that each piece reflects the highest levels of craftsmanship and precision. As a trusted partner to industries worldwide, our goal is to ensure the longevity and efficiency of every welding project.

Product Parameters

Below are the detailed specifications of the molybdenum welding electrodes, structured in three unique tables to cover physical properties, mechanical properties, and dimensional parameters.

Table 1: Physical Properties

| Property | Value |

|---|---|

| Melting Point | 2,623°C |

| Thermal Conductivity | 138 W/m·K |

| Density | 10.28 g/cm³ |

| Coefficient of Expansion | 4.8 x 10⁻⁶/K |

| Electrical Conductivity | 19.7 MS/m |

Table 2: Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 690 MPa |

| Yield Strength | 480 MPa |

| Elongation | 25% |

| Hardness (Vickers) | 250 HV |

| Fracture Toughness | 17 MPa·m^1/2 |

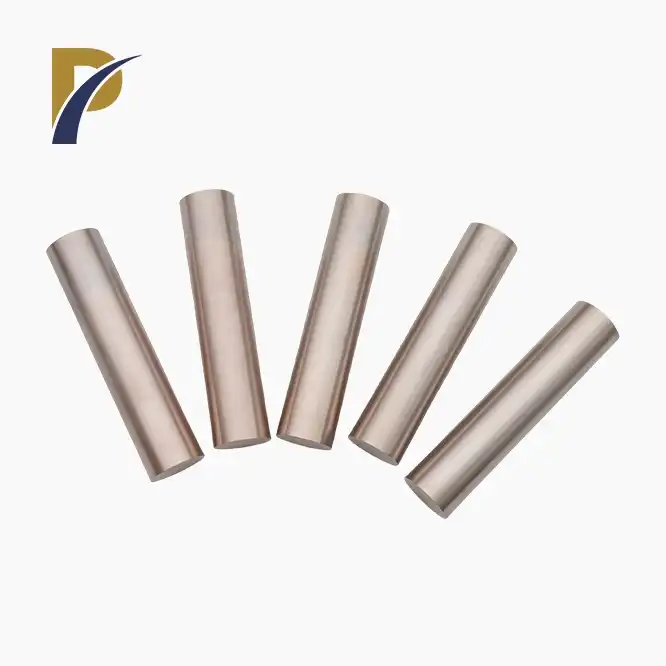

| Diameter | 10~100mm |

| Length | 150~3000mm |

| Purity | 99.97% |

| Density | 10.2g/cm3 |

| Straightness |

Forging rod ≤1% Sintered rod ≤2% |

| Elongation | ≥10% |

| Melting Point | 2620℃ |

|

|

|

|

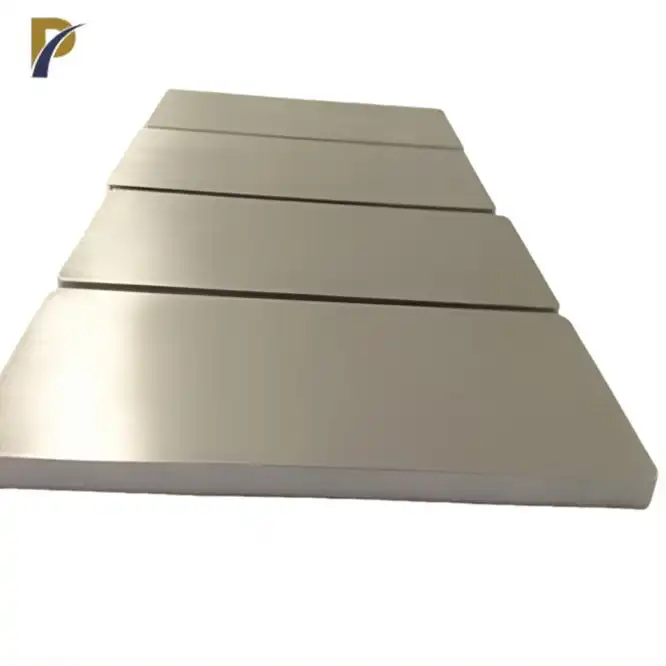

Physical and Mechanical Properties

Molybdenum welding electrodes are renowned for their unique combination of high thermal and electrical conductivity, low coefficient of expansion, and remarkable hardness. These features allow the electrodes to maintain their structural integrity even in high-temperature environments. The mechanical strength of molybdenum electrodes ensures that they can withstand intense mechanical stress, making them suitable for heavy-duty applications.

|

|

Product Functions

- High-Temperature Resistance: Molybdenum welding electrodes can endure temperatures exceeding 2600°C, making them ideal for high-heat applications such as plasma welding and arc welding.

- Corrosion Resistance: These electrodes offer excellent resistance to corrosion in acidic and oxidizing environments, ensuring long-lasting performance in chemically aggressive conditions.

- Electrical Conductivity: Molybdenum’s superior electrical conductivity ensures efficient energy transfer during the welding process, leading to high-quality welds with minimal energy loss.

- Dimensional Stability: Due to the low coefficient of thermal expansion, molybdenum electrodes maintain their shape and dimensions even when subjected to rapid temperature fluctuations.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- Aerospace Industry: Molybdenum welding electrodes are widely used in the aerospace sector for welding components that require high-strength and temperature resistance, such as turbine blades and heat shields.

- Power Generation: These electrodes are essential in the manufacture and repair of power plant components, particularly in the welding of parts exposed to extreme heat, such as boilers and heat exchangers.

- Chemical Processing: Molybdenum electrodes are commonly employed in the chemical processing industry, where they are used to weld equipment exposed to corrosive substances, including pipes and reactors.

- Electronics Manufacturing: Due to their high electrical conductivity, molybdenum electrodes are used in the fabrication of electrical components that require precision welding, such as circuits and connectors.

|

|

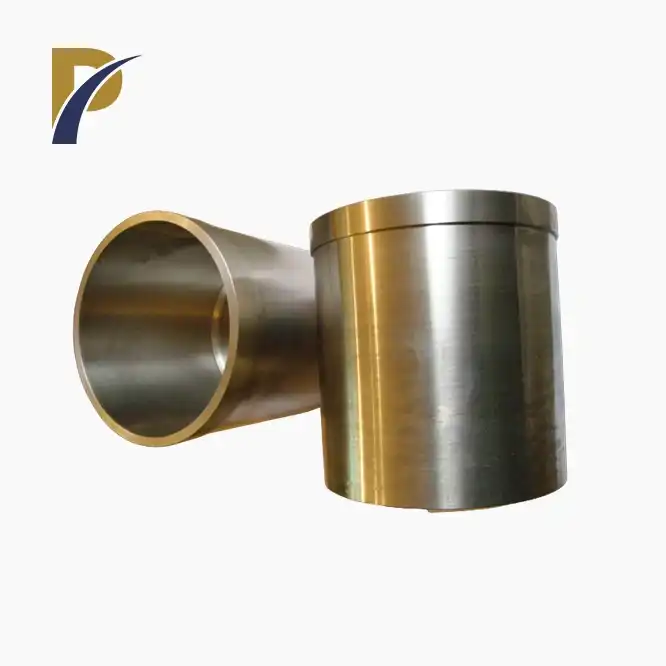

Product Process and Production Flow

Our molybdenum welding electrodes are produced using a stringent quality-controlled manufacturing process to ensure consistency and high performance. The process involves:

- Material Selection: High-purity molybdenum is sourced to ensure the final product meets stringent industry standards.

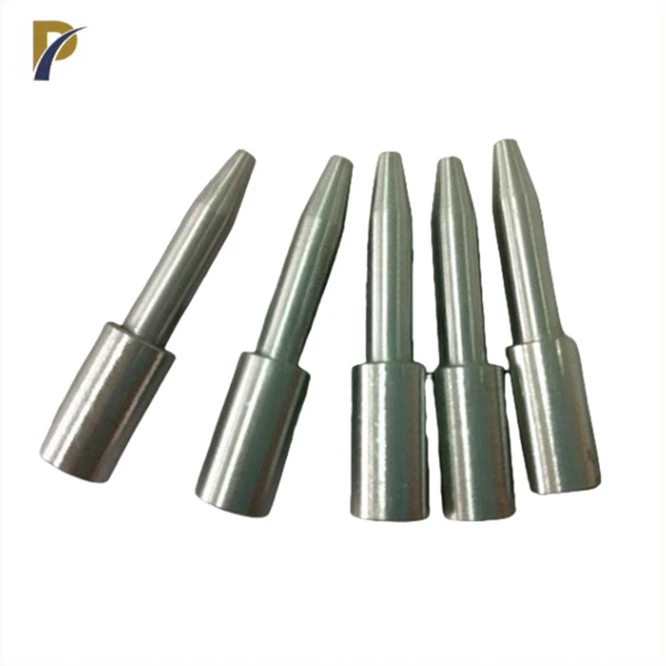

- Forming and Rolling: The material is then subjected to forming and rolling operations, where it is shaped to the desired dimensions.

- Sintering: Electrodes undergo sintering at high temperatures to enhance mechanical properties, such as strength and hardness.

- Machining: Precision machining is performed to ensure the electrodes meet exact dimensional tolerances.

- Quality Inspection: Each electrode is inspected for defects and tested for mechanical and physical properties to ensure they meet the specifications required for high-performance welding.

|

|

|

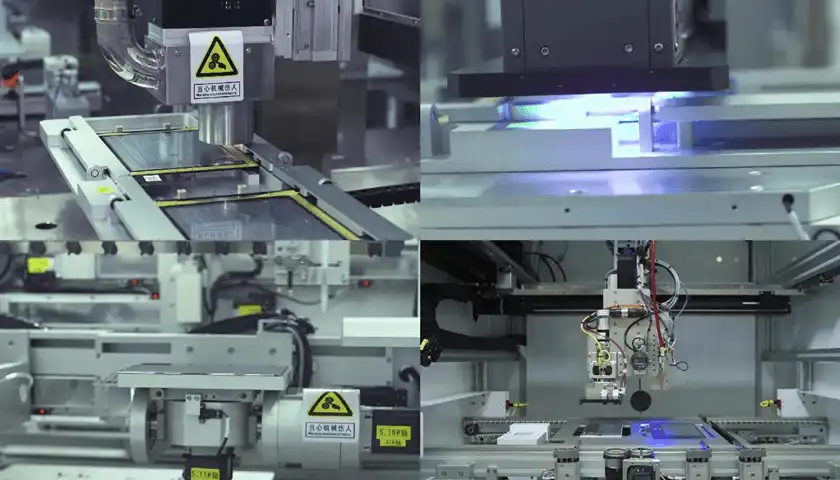

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts a state-of-the-art production facility equipped with advanced technology and machinery. Our production lines are designed for efficiency and precision, allowing us to produce high-quality molybdenum welding electrodes that meet the demands of a global market. Our factory is home to numerous advanced machines, including vacuum arc furnaces, plasma welding systems, and CNC machining centers, ensuring that each product is manufactured to exact specifications.

|

|

|

|

Logistics and Packaging

- Wooden Packaging: For heavy and fragile shipments, we use custom-built wooden crates to ensure safety during transit.

- Carton Packaging: For smaller orders, our products are securely packaged in durable, high-quality cartons.

- Foam-Filled Packaging: Foam inserts are used to protect delicate products from shock during transportation.

- Waterproof and Moisture-Proof Packaging: We employ specialized packaging materials to protect products from environmental factors.

- Customized Packaging: Tailor-made packaging options are available to meet the specific requirements of our clients.

- International Standard Packaging: All our packaging complies with international standards for safe and secure shipping.

|

|

|

|

|

|

|

|

Why Choose Us?

- Comprehensive Expertise: With over a decade of experience, we have established ourselves as experts in the production of non-ferrous metals, including molybdenum welding electrodes.

- High-Quality Products: We utilize the latest technology to manufacture electrodes that meet the highest industry standards, ensuring consistent performance and durability.

- Global Reach: Our products are exported to various countries, including the U.S., Germany, South Korea, and Iran, where we have established long-term relationships with clients.

- Custom Solutions: We offer a wide range of OEM/ODM services, allowing clients to receive products that meet their specific needs.

- Advanced Manufacturing Facilities: Our factory is equipped with cutting-edge machinery, ensuring precision and quality control throughout the production process.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we provide customized manufacturing services for molybdenum welding electrodes. We work closely with our clients to ensure that the electrodes meet their exact specifications, from material selection to final product dimensions. Whether you need a specialized alloy or a particular size, we can tailor our production process to suit your needs.

|

|

FAQ

-

What is the typical lead time for orders?

Lead times vary depending on the size of the order, but typical production times range from 3 to 4 weeks. -

Do you offer sample orders?

Yes, we offer free samples for quality evaluation. Please contact us for more details. -

What payment methods do you accept?

We accept wire transfers, letters of credit, and PayPal for international orders. -

Can you produce electrodes to custom specifications?

Absolutely. We specialize in providing custom solutions for our clients. -

What is your quality control process?

All products undergo rigorous testing for mechanical and physical properties before they are approved for shipment.

Contact Us

If you're looking for high-quality molybdenum welding electrodes that meet your specific requirements, look no further than Shaanxi Peakrise Metal Co., Ltd. Our experienced team is ready to assist you with your order and provide the best solutions for your welding needs.

Contact us today at info@peakrisemetal.com for more information and to discuss your project requirements. We look forward to building a successful partnership with you!