molybdenum crucible liner

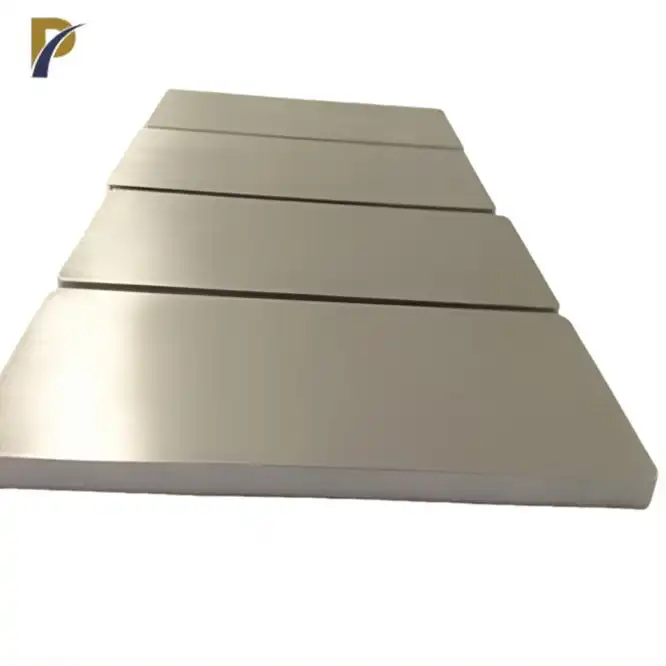

Purity: 99.95%

Density: 10.2g/cm3

Shape: Crucible

Diameter: Max.450mm

Height: Max.800mm

Finish: Ra<1.6

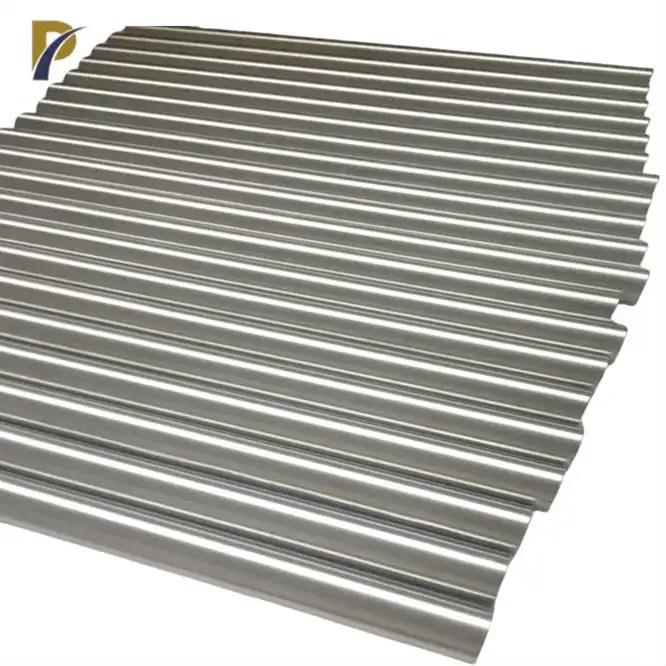

Craft: Sintering,Machined

Application: Metallurgical industry, rare earth industry, monocrystalline silicon, solar energy, artificial crystal and mechanical processing industries.

PRODUCT DESCRIPTION

Molybdenum Crucible Liner – Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Molybdenum crucible liners are essential in industries requiring high-temperature processes such as crystal growth, metallurgy, and rare-earth smelting. As a high-melting-point metal, molybdenum offers superior heat resistance, making it ideal for applications demanding thermal stability and chemical resistance. Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of molybdenum crucible liners, with years of expertise in the production and export of non-ferrous metals. Our company provides customized molybdenum crucible liners tailored to client needs, ensuring high performance in extreme conditions. With a focus on quality and innovation, we cater to various industries worldwide, supplying top-grade molybdenum products that meet international standards. Our crucibles are widely used in high-temperature furnaces, vacuum systems, and crystal growth chambers, with a reputation for excellent thermal conductivity, wear resistance, and durability.

Product Parameters Table

| Parameter | Value |

|---|---|

| Molybdenum Purity | ≥ 99.95% |

| Melting Point | 2,623°C |

| Density | 10.2 g/cm³ |

| Thermal Conductivity | 138 W/m·K (at 20°C) |

| Max Operating Temperature | 1,900°C |

| Crucible Diameter Range | 50mm – 500mm |

| Height Range | 100mm – 1,000mm |

| Wall Thickness | 2mm – 10mm |

| Chemical Composition | Percentage |

|---|---|

| Molybdenum (Mo) | ≥ 99.95% |

| Oxygen (O) | ≤ 0.003% |

| Carbon (C) | ≤ 0.01% |

| Nitrogen (N) | ≤ 0.002% |

| Silicon (Si) | ≤ 0.002% |

| Mechanical Properties | Value |

|---|---|

| Tensile Strength | 690 MPa |

| Yield Strength | 470 MPa |

| Elongation | 25% |

| Hardness (Rockwell) | HRA 88 |

Product Functions

- Thermal Stability: Molybdenum's ability to withstand extreme temperatures makes it ideal for high-temperature furnaces and vacuum environments.

- Corrosion Resistance: It resists corrosion and oxidation, making it perfect for applications in chemically reactive environments.

- High Thermal Conductivity: The material’s ability to conduct heat efficiently enhances its use in crystal growth and semiconductor manufacturing.

- Mechanical Strength: High tensile strength and durability ensure that the crucible liner maintains structural integrity during extended use.

- Wear Resistance: Molybdenum's wear-resistant properties allow it to endure continuous exposure to thermal cycling without degradation.

|

|

|

Product Applications

Molybdenum crucible liners have a wide range of applications in industries that require high-temperature processing and chemical resistance:

- Semiconductor Industry: Used in the production of LED substrates and other semiconductor materials.

- Metallurgy: Essential for smelting rare earth metals and alloys due to its heat resistance.

- Crystal Growth: Widely used in sapphire crystal growth and other high-purity crystal production processes.

- Aerospace: Applied in the manufacture of high-performance components that require excellent thermal stability.

- Solar Energy: Utilized in thin-film deposition processes for solar panel production.

- Vacuum Furnaces: Ideal for vacuum environments where stability and resistance to contamination are critical.

|

|

Our Factory

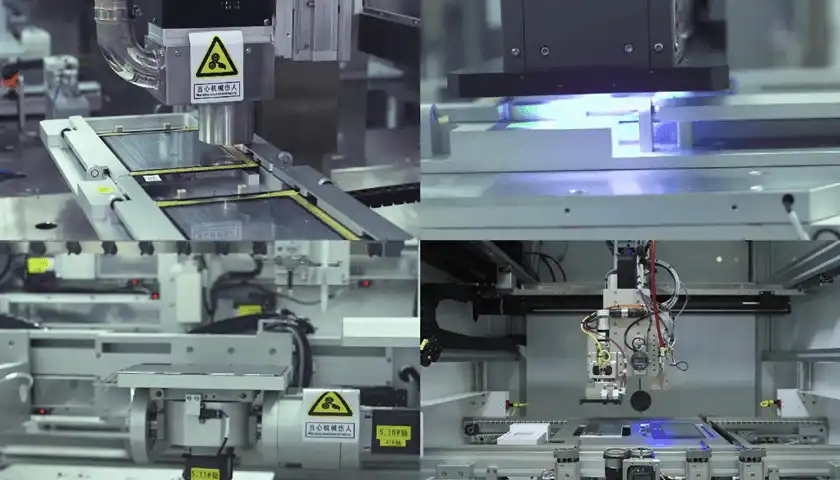

Shaanxi Peakrise Metal Co., Ltd. is equipped with state-of-the-art production facilities, including vacuum arc melting furnaces, electron beam melting machines, and CNC machining centers. Our factory employs over 150 skilled workers and technicians, ensuring that every molybdenum crucible liner meets stringent quality standards. With a comprehensive R&D department and ISO 9001 certification, we are committed to continuous improvement and innovation in our production processes.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

-

Packaging Options:

- Wooden crates for large shipments.

- Carton packaging with foam filling for smaller items.

- Waterproof and moisture-proof packaging for products sensitive to environmental conditions.

- Customized packaging solutions for specific customer needs.

- All packaging complies with international shipping standards.

-

Logistics Options:

- Sea Freight: Ideal for bulk shipments with cost-effective solutions.

- Air Freight: For urgent orders requiring faster delivery times.

- Land Transport: Used for regional deliveries and short-haul destinations.

- Multimodal Transport: A combination of sea, air, and land transport for optimized logistics.

- Courier Services: Fast and secure delivery for small packages worldwide.

|

|

|

|

|

|

|

|

Why Choose Us?

- Industry Expertise: With over a decade of experience in non-ferrous metals, we are leaders in molybdenum crucible liner production.

- Comprehensive Services: We offer complete manufacturing, material research, and quality testing solutions under one roof.

- Global Reach: Our products are exported to over 10 countries, including the U.S., Germany, and South Korea.

- Quality Assurance: Every product undergoes stringent testing, ensuring it meets or exceeds industry standards.

- Advanced Production Facilities: We have the latest production equipment to ensure the highest precision and quality.

- Customer-Centric Approach: We prioritize customer satisfaction with tailored solutions and responsive support.

|

|

|

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. provides customized OEM and ODM services. Whether you need specific dimensions, unique packaging, or tailored designs, we have the expertise to meet your requirements. Our advanced production facilities allow us to handle custom orders efficiently, ensuring quick turnaround times and competitive pricing for bulk orders.

|

|

FAQ

- What is the purity of your molybdenum crucible liners?

- Our crucible liners have a molybdenum purity of ≥99.95%.

- Can you produce custom-sized crucibles?

- Yes, we provide custom sizes according to client specifications.

- What industries use molybdenum crucible liners?

- They are commonly used in semiconductor manufacturing, metallurgy, aerospace, and high-temperature furnace applications.

- How do you ensure product quality?

- Each product undergoes rigorous testing, including dimensional checks, tensile strength testing, and purity analysis.

- What are your packaging options?

- We offer wooden, carton, and customized packaging with waterproof and moisture-proof materials to ensure safe delivery.

Call to Action (CTA) – Contact Us

Are you looking for a reliable supplier of high-quality molybdenum crucible liners? Contact Shaanxi Peakrise Metal Co., Ltd. today to discuss your project requirements and receive a customized quote. Our team is ready to assist you with any inquiries. Reach out to us at info@peakrisemetal.com and let us provide you with the best solutions for your high-temperature applications.