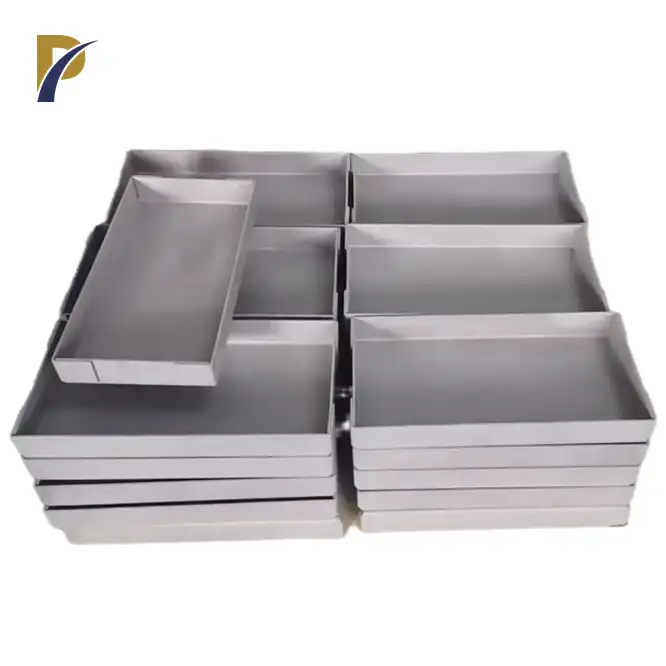

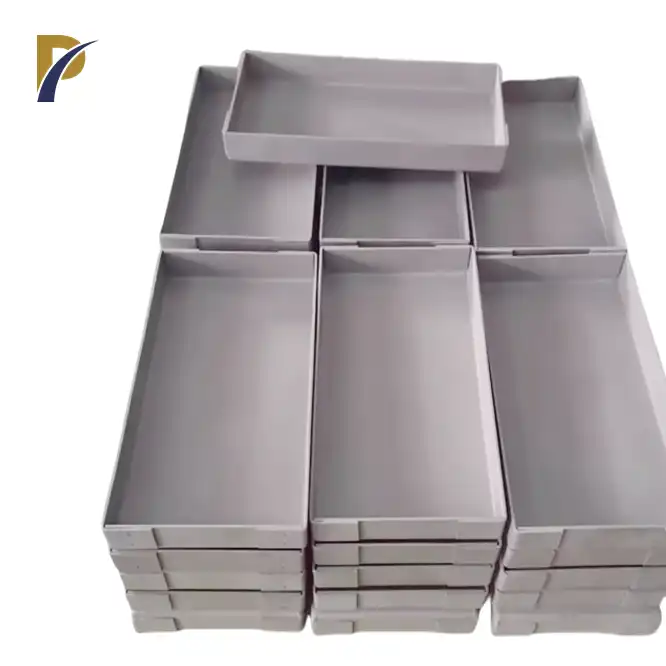

molybdenum alloy boat

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Product Introduction

Molybdenum alloy boats are critical components in industries that require high-temperature resistance, durability, and efficiency. These boats are made from molybdenum alloys, which have excellent thermal stability, high melting points, and strong corrosion resistance. They are primarily used in applications such as vacuum coating, sintering, and metal evaporation. As a leading supplier of molybdenum alloy boats, Shaanxi Peakrise Metal Co., Ltd. has established itself as a global player in the production and export of non-ferrous metal products. Our molybdenum alloy boats are recognized for their superior quality, strength, and reliability, providing solutions to complex industrial processes that demand precision and durability.

Since 2010, Shaanxi Peakrise Metal Co., Ltd. has focused on providing high-quality non-ferrous metals to international markets. We have invested heavily in research and development, manufacturing, and testing, allowing us to meet the strict standards required by our customers worldwide. Our commitment to innovation and quality ensures that our molybdenum alloy boats are used in industries as diverse as electronics, aerospace, and energy. Whether your business requires standard or custom molybdenum alloy boats, Shaanxi Peakrise Metal Co., Ltd. is your trusted partner in delivering excellence.

Product Parameters

Grade: Mo1, MoLa, TZM

Purity: 99.95%

Density: 10.2g/cm³

Specifications: Customization is supported, and processing can be done according to drawings

State: Hot processing state

Production process: molybdenum powder-pressing-sintering-forging-turning-riveting-inspection-delivery

Surface color: oxidized black leather surface, white (alkali washing surface)

| Grade | Main chemical content% | Impurity content(<%) | |||||||||

| Mo | Ti | Zr | C | La2O3 | C | 0 | N | Fe | Ni | Si | |

| Mo1 | Remain | — | — | — | — | 0.01 | 0.007 | 0.002 | 0.01 | 0.002 | 0.01 |

| TZM | Remain | 0.40~0.55 | 0.06~0.12 | 0.01~0.04 | — | — | 0.03 | 0.002 | 0.01 | 0.005 | 0.005 |

| MoLa | Remain | — | — | — | 0.4~1.2 | 0.01 | — | 0.002 | 0.01 | 0.002 | 0.01 |

|

|

|

Physical and Chemical Properties

Molybdenum alloys are known for their exceptional physical and chemical properties, making them ideal for high-stress industrial applications. These properties include:

- High Melting Point: Molybdenum alloy boats can withstand temperatures of up to 1700°C, making them ideal for high-temperature processes.

- Thermal Conductivity: Molybdenum alloys have excellent thermal conductivity, ensuring uniform heat distribution during the evaporation or sintering process.

- Corrosion Resistance: These alloys resist corrosion in harsh environments, prolonging the lifespan of the boats in chemically aggressive settings.

- Mechanical Strength: Molybdenum alloy boats maintain their strength and form even under extreme heat, which reduces deformation risks during use.

- Low Coefficient of Thermal Expansion: This property helps the boats maintain dimensional stability, even when subjected to rapid temperature changes.

Product Functions

- High-Temperature Resistance: Molybdenum alloy boats are engineered to perform in extreme heat, maintaining their structural integrity in temperatures up to 1700°C.

- Efficient Heat Distribution: Due to their excellent thermal conductivity, these boats ensure even heat distribution, enhancing the efficiency of coating and sintering processes.

- Corrosion Protection: The molybdenum alloys provide outstanding resistance to oxidation and chemical corrosion, essential for processes involving aggressive gases or metals.

- Durability: These boats have a long operational life, reducing the frequency of replacement and downtime in industrial settings.

- Customization Flexibility: Available in various shapes and sizes, these boats can be tailored to meet the specific needs of different industrial applications.

|

|

|

Product Applications

- Vacuum Coating: Molybdenum alloy boats are commonly used in the vacuum coating of metals and glass. Their ability to withstand high temperatures ensures high-quality coatings.

- Sintering: These boats are ideal for the sintering process in powder metallurgy, where materials are heated just below their melting point to bond particles together.

- Metal Evaporation: Molybdenum alloy boats facilitate the evaporation of metals in vacuum deposition systems, ensuring a uniform coating in the manufacturing of semiconductors and electronic components.

- Aerospace: In aerospace applications, molybdenum alloy boats are used in processes that require materials to withstand high temperatures and corrosive environments.

- Energy Sector: These boats are used in energy industries for processes like hydrogen production, where high-temperature operations are crucial.

Product Process and Production Flow

Shaanxi Peakrise Metal Co., Ltd. employs a robust production process to ensure the highest quality molybdenum alloy boats. The process includes:

- Raw Material Selection: We use only the highest-purity molybdenum alloys, ensuring consistent performance across all applications.

- Melting and Casting: Using vacuum arc melting and intermediate frequency sintering, we form the initial alloy ingots with high precision.

- Rolling and Stamping: The alloy is rolled to the desired thickness and stamped into the boat shapes required for specific applications.

- Surface Treatment: The boats are polished, machined, or coated to meet customer specifications.

- Quality Testing: Every batch undergoes rigorous testing, including tensile strength, hardness, and corrosion resistance tests, to ensure compliance with international standards.

Precision-Engineered Molybdenum Alloy Boats Tailored to Your Needs!

At Peakrise Metal, your requirements take top priority. With over a decade of expertise, we transform complex ideas into practical solutions through our precision-engineered molybdenum alloy boats. From initial design to detailed specification adjustments, every stage of our manufacturing process is customized to meet your exact demands.

Customization Options for Molybdenum Alloy Boats:

-

Size and Shape: Customize the length, width, and overall design to fit specific application needs, ensuring compatibility with different equipment and operating conditions.

-

Purity: Select from various molybdenum purity levels to achieve the required performance for specialized applications.

-

Coating Treatment: Enhance performance and longevity with tailored coatings, such as anti-oxidation or conductive layers, to suit specific environments.

-

Connection Design: Customize connection methods, such as welded joints or bolted structures, for secure and efficient installation.

-

Packaging: Opt for customized packaging solutions designed for safe transportation and storage, ensuring product integrity upon arrival.

Why choose molybdenum alloy boat from Peakrise Metal?

At Peakrise Metal, we uphold the highest industry standards by integrating advanced techniques, innovative technology, and unmatched expertise. Our unwavering commitment ensures that your specific needs are met with premium molybdenum alloy boat solutions.

Expertise and Experience: With over a decade in the industry, Peakrise Metal combines advanced technology and deep expertise to deliver high-quality molybdenum alloy boats tailored to your precise requirements.

Custom Solutions: We offer personalized solutions, including custom sizes, shapes, and coatings, ensuring our molybdenum alloy boats meet exact specifications and performance demands.

Unmatched Quality: Our commitment to superior manufacturing standards guarantees that each molybdenum alloy boat delivers outstanding performance, durability, and reliability, providing excellent value for your investment.

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art production facility equipped with cutting-edge machinery. Our manufacturing capabilities include vacuum arc melting furnaces, plasma welding rooms, and CNC machines, enabling us to produce a wide variety of molybdenum alloy products. We pride ourselves on our ability to meet large-scale production demands while maintaining strict quality controls, as evidenced by our ISO 9001:2015 certification.

Logistics Options:

Sea Freight: Economical shipping for large orders.

Air Freight: Faster delivery for urgent needs.

Land Freight: Flexible delivery within certain regions.

Multimodal Transport: Combining different methods for optimal shipping solutions.

Courier Services: Small package deliveries via international couriers.

Why Choose Us?

Rich Experience: With over a decade of experience in non-ferrous metal production, Shaanxi Peakrise Metal Co., Ltd. has become a trusted name in the global market.

High-Quality Products: We focus on delivering molybdenum alloy boats with unmatched durability, precision, and resistance to extreme conditions.

Advanced Manufacturing: Our factory is equipped with the latest machinery, enabling us to meet high production demands while maintaining stringent quality standards.

Customization Capabilities: We offer OEM services tailored to the specific needs of our clients, ensuring that every molybdenum alloy boat meets your exact requirements.

Global Reach: Our products are exported to multiple countries, including the United States, Germany, and South Korea, with long-term partnerships with international clients.

FAQ

What is the maximum temperature that molybdenum alloy boats can withstand?

Molybdenum alloy boats can handle temperatures up to 1700°C.

Can I order custom-sized molybdenum boats?

Yes, we offer fully customizable molybdenum alloy boats according to your specifications.

Do you provide certification for your products?

All our products come with ISO 9001:2015 certification and other relevant quality certificates.

How do you ensure the quality of the boats?

Each product undergoes rigorous testing for tensile strength, corrosion resistance, and dimensional accuracy.

What are the shipping options?

We offer sea, air, land, multimodal transport, and courier services based on the size and urgency of the order.

Contact Us

Interested in learning more about our molybdenum alloy boats or placing an order? Contact us today! Our team is ready to assist you with all your inquiries. Email us at info@peakrisemetal.com to discuss your project needs. We look forward to building a successful partnership!