Composition and Microstructure of Molybdenum TZM Alloy

Chemical Composition

Molybdenum TZM alloy is a carefully engineered material that derives its exceptional properties from its precise chemical composition. The alloy typically consists of 99% molybdenum, with small but crucial additions of titanium (0.5%) and zirconium (0.08%). These alloying elements play a vital role in enhancing the material's overall performance. Titanium contributes to improved strength and ductility, while zirconium aids in grain refinement and increases the alloy's recrystallization temperature. The synergistic effect of these elements results in a material that surpasses the capabilities of pure molybdenum in many aspects.

Microstructural Features

The microstructure of molybdenum TZM alloy is characterized by its fine-grained nature, which is a key factor in its superior mechanical properties. The addition of titanium and zirconium promotes the formation of small, dispersed carbide particles throughout the molybdenum matrix. These carbides act as obstacles to dislocation movement, effectively strengthening the alloy. The grain structure is typically equiaxed, with an average grain size that can be controlled through careful processing techniques. This refined microstructure contributes to the alloy's excellent creep resistance and maintains its strength at high temperatures.

Processing and Heat Treatment

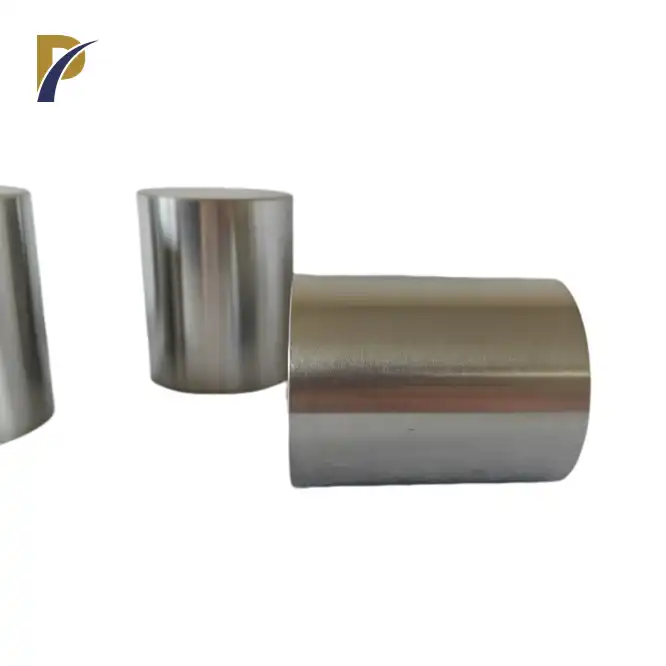

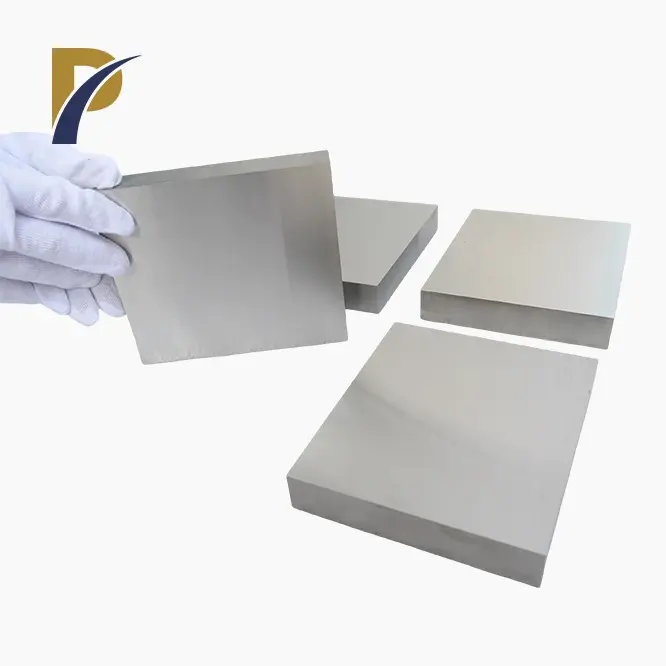

The production of molybdenum TZM alloy involves sophisticated processing methods to achieve its desired properties. The alloy is typically produced through powder metallurgy techniques, followed by hot working processes such as extrusion or forging. These processes help to develop the alloy's characteristic microstructure and enhance its mechanical properties. Heat treatment plays a crucial role in optimizing the alloy's performance. Stress-relieving annealing is often employed to reduce residual stresses and improve dimensional stability. The precise control of heat treatment parameters allows for tailoring the alloy's properties to meet specific application requirements.

|

|

Mechanical and Thermal Properties of TZM Alloy

Strength and Hardness

Molybdenum TZM alloy exhibits exceptional strength characteristics, particularly at elevated temperatures. Its room temperature tensile strength typically ranges from 760 to 1000 MPa, significantly higher than that of pure molybdenum. What sets TZM alloy apart is its ability to maintain high strength levels even at temperatures exceeding 1000°C. The alloy's yield strength at 1000°C can be as high as 380 MPa, making it suitable for high-stress applications in extreme environments. The hardness of TZM alloy is also noteworthy, with Vickers hardness values ranging from 220 to 250 HV. This combination of strength and hardness contributes to the alloy's excellent wear resistance and structural integrity under demanding conditions.

Thermal Conductivity and Expansion

One of the most valuable properties of molybdenum TZM alloy is its exceptional thermal conductivity. At room temperature, the thermal conductivity of TZM alloy is approximately 138 W/m·K, which is higher than many other high-temperature alloys. This high thermal conductivity makes TZM alloy an excellent choice for applications requiring efficient heat dissipation. Equally important is the alloy's low coefficient of thermal expansion, which is about 5.2 × 10^-6 /K at room temperature. This low expansion rate ensures dimensional stability in applications involving temperature fluctuations, making TZM alloy ideal for precision components in high-temperature systems.

Creep Resistance and High-Temperature Behavior

Molybdenum TZM alloy's outstanding creep resistance is one of its defining features. The alloy maintains its structural integrity and resists deformation under sustained loads at high temperatures, a property crucial for long-term reliability in extreme environments. The creep strength of TZM alloy at 1200°C for 100 hours can exceed 140 MPa, significantly outperforming many other refractory metals and alloys. This exceptional creep resistance is attributed to the alloy's fine-grained structure and the presence of stable carbide dispersions. Additionally, TZM alloy exhibits excellent high-temperature strength retention, with minimal loss of mechanical properties up to temperatures as high as 1600°C. This combination of creep resistance and high-temperature strength makes TZM alloy an indispensable material in applications such as furnace components, rocket nozzles, and nuclear reactor parts.

Applications and Future Prospects of Molybdenum TZM Alloy

Aerospace and Rocketry

In the aerospace and rocketry sectors, molybdenum TZM alloy has found numerous critical applications due to its exceptional high-temperature properties. The alloy is extensively used in rocket engine components, particularly in nozzle throats and heat shields, where it must withstand extreme temperatures and erosive environments. TZM alloy's high strength-to-weight ratio and excellent thermal management capabilities make it an ideal choice for these demanding applications. In hypersonic aircraft development, TZM alloy is being explored for use in leading edges and control surfaces, where its ability to maintain structural integrity under intense heat and aerodynamic forces is crucial. As space exploration continues to push technological boundaries, the role of TZM alloy in enabling more advanced and durable spacecraft components is likely to expand.

|

|

Nuclear Energy and Fusion Research

The nuclear energy industry has long recognized the value of molybdenum TZM alloy in various applications. In nuclear fission reactors, TZM alloy is used in fuel element cladding, control rod guide tubes, and other core components that require high temperature strength and radiation resistance. The alloy's low neutron absorption cross-section and excellent dimensional stability under irradiation make it particularly suitable for these applications. In the realm of nuclear fusion research, TZM alloy is being investigated for use in plasma-facing components and divertor plates in experimental fusion reactors. Its high melting point, good thermal conductivity, and resistance to plasma erosion position it as a promising material for future fusion power plants. As the world continues to seek clean and efficient energy sources, the role of TZM alloy in advancing nuclear technology is expected to grow.

Advanced Manufacturing and Industrial Processes

Molybdenum TZM alloy has found widespread use in advanced manufacturing and industrial processes that involve high temperatures and corrosive environments. In the glass industry, TZM alloy is used to manufacture stirrers, feeders, and other components that come into contact with molten glass, taking advantage of the alloy's resistance to glass adhesion and its ability to maintain strength at high temperatures. In the semiconductor industry, TZM alloy is utilized in high-temperature furnace components and wafer carriers, where its dimensional stability and cleanliness are crucial. Looking to the future, the alloy's potential in additive manufacturing is being explored, with researchers investigating its use in 3D printing of complex, high-performance components for extreme environments. As industrial processes continue to push the limits of material capabilities, molybdenum TZM alloy is poised to play an increasingly important role in enabling more efficient and durable manufacturing solutions.

Conclusion

Molybdenum TZM alloy stands as a confirmation to the control of progressed materials building. Its interesting combination of high-temperature quality, crawl resistance, and warm properties makes it an vital fabric in a few of the most requesting applications over aviation, atomic vitality, and progressed fabricating segments. As we proceed to thrust the boundaries of innovation and investigate unused wildernesses in space and vitality generation, the significance of materials like TZM combination cannot be exaggerated. The continuous investigate and improvement in this field guarantee to open indeed more potential applications for this exceptional combination, guaranteeing its put at the cutting edge of materials science for a long time to come.

Contact Us

To learn more about molybdenum TZM alloy and how it can benefit your specific applications, please don't hesitate to reach out to our team of experts. Contact us at info@peakrisemetal.com for personalized assistance and to explore our range of high-quality TZM alloy products.