Corrosion Resistant Zr Wire

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Corrosion Resistant Zr Wire - High-Performance Zirconium Alloy Supplier | Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

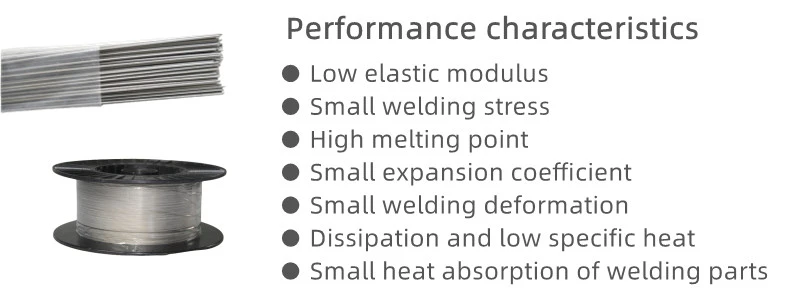

Corrosion-resistant zirconium (Zr) wire is a high-performance material widely used in demanding industrial applications where resistance to corrosion and high temperatures are crucial. Due to its exceptional chemical resistance, especially in harsh environments such as acidic and alkaline solutions, zirconium wire is an essential material in industries like chemical processing, nuclear energy, and medical technology.

At Shaanxi Peakrise Metal Co., Ltd., we specialize in providing high-quality zirconium products, including corrosion-resistant Zr wire, to meet the diverse needs of our global clientele. With years of experience in non-ferrous metal production and export, we have established a solid reputation for delivering superior products, customized to meet industry specifications and client requirements. Our corrosion-resistant Zr wire is manufactured to the highest standards and is available in various sizes and grades, ensuring that we can meet the exact demands of your application. As an experienced supplier in the field, we have continuously evolved to provide the most advanced, reliable, and corrosion-resistant zirconium materials to our customers worldwide.

Zirconium wire is particularly well-suited for use in environments requiring materials that withstand corrosion from aggressive chemicals, including chlorine, hydrochloric acid, and sulfuric acid. Its exceptional corrosion resistance, combined with its mechanical strength, makes it a preferred material in industries that require long-term durability and low maintenance. Our zirconium wire is rigorously tested to ensure it meets stringent quality control standards, giving you confidence in the product’s performance and reliability.

Product Specifications

| Parameter | Value |

|---|---|

| Diameter Range | 0.1 mm to 5.0 mm |

| Purity | ≥ 99.6% |

| Tensile Strength | 400 MPa - 600 MPa |

| Elongation | ≥ 20% |

| Density | 6.51 g/cm³ |

| Surface Finish | Bright, Polished |

| Mechanical Properties | Zr702 Grade | Zr705 Grade |

|---|---|---|

| Yield Strength | 280 MPa | 380 MPa |

| Hardness | 120 HV | 160 HV |

| Electrical Conductivity | 2.5% IACS | 2.0% IACS |

| Melting Point | 1855°C | 1850°C |

| Thermal Expansion | 5.7 x 10⁻⁶/°C | 5.6 x 10⁻⁶/°C |

| Chemical Composition | Max Allowable (%) |

|---|---|

| Hafnium (Hf) | 4.5% |

| Iron (Fe) | 0.2% |

| Nitrogen (N) | 0.025% |

| Carbon (C) | 0.05% |

| Oxygen (O) | 0.16% |

|

|

|

Physical and Chemical Properties

- Corrosion Resistance: Outstanding resistance to both acidic and alkaline environments, especially in chloride-rich solutions.

- Thermal Stability: Can operate at high temperatures up to 500°C, making it suitable for high-temperature industrial processes.

- Biocompatibility: Zirconium is non-toxic and biocompatible, which makes it ideal for medical applications, such as implants and surgical instruments.

- Low Thermal Neutron Cross-Section: Suitable for use in nuclear reactors where low neutron absorption is critical.

| Content | Zr+Hf | Hf | Fe+Cr | O | H | N | C | Each impurity | Total impurity |

| Standard value | ≥99.0 | ≤4.5 | ≤0.2 | 0.11-0.15 | ≤0.05 | ≤0.015 | ≤0.03 | ≤0.05 | ≤0.2 |

| Typical value | 99.3 | 1.91 | 0.04 | 0.12 | 0.004 | 0.005 | 0.006 | - | 0.002 |

Product Functions

- Corrosion Resistance: Zirconium wire has an inherent ability to resist corrosion, making it ideal for environments exposed to aggressive chemicals like chlorine, acids, and bases.

- High Temperature Endurance: Its ability to maintain structural integrity at elevated temperatures makes it perfect for high-temperature applications in industries such as power generation and chemical processing.

- Electrical Conductivity: While not as conductive as copper, zirconium has good electrical conductivity, allowing it to be used in specialized electrical applications where both corrosion resistance and conductivity are required.

- Durability: The long-lasting nature of zirconium makes it a cost-effective solution for industries that require materials with a long operational life.

Product Applications

- Chemical Processing: Widely used in chemical reactors, heat exchangers, and pipes due to its ability to withstand corrosive environments without degradation.

- Nuclear Industry: Zirconium wire is essential in nuclear reactors as it has low neutron absorption, which enhances reactor efficiency while maintaining structural integrity.

- Medical Applications: Thanks to its biocompatibility, zirconium wire is utilized in the manufacturing of medical devices such as surgical tools and orthopedic implants.

- Aerospace Industry: In aerospace applications, where both strength and resistance to environmental stress are required, zirconium wire is used for components exposed to extreme conditions.

- Electronics: In specialized electronic components, zirconium’s electrical properties and corrosion resistance make it a vital material.

Manufacturing Process

Our zirconium wire is produced using state-of-the-art equipment and stringent quality control processes:

- Raw Material Selection: Premium zirconium ore is sourced from verified suppliers to ensure purity and consistency.

- Melting: Zirconium is melted in a vacuum arc furnace, ensuring the material's purity and minimizing contamination.

- Casting: The molten metal is cast into ingots, which are then processed into wire form.

- Drawing and Rolling: The ingots are drawn through a series of dies to achieve the desired diameter, ensuring uniformity in thickness.

- Surface Treatment: The wire is polished or coated, as per customer requirements, to enhance its surface properties.

- Quality Control: Every batch is inspected and tested for mechanical properties, chemical composition, and corrosion resistance.

Why Choose Us?

- Extensive Industry Experience: Shaanxi Peakrise Metal Co., Ltd. has over a decade of experience in manufacturing non-ferrous metals, including tungsten, molybdenum, tantalum, and zirconium.

- Global Reach: We serve customers across the globe, with a strong presence in the USA, Europe, and Asia.

- Advanced Manufacturing Facilities: Our facilities include vacuum arc melting furnaces, rolling mills, and precision drawing machines, enabling us to maintain stringent quality standards.

- Customizable Solutions: We provide OEM and ODM services to ensure that your specific needs are met with tailored solutions.

- Commitment to Quality: All products undergo rigorous testing to ensure compliance with international standards.

- Fast Lead Times: Our efficient production processes ensure that orders are fulfilled promptly without compromising on quality.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer comprehensive OEM/ODM services for zirconium wire. Whether you need specific sizes, coatings, or packaging, we can customize our products to meet your exact requirements. Our dedicated R&D team is available to collaborate with you on product development, ensuring that you receive a solution that perfectly fits your needs.

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

Packaging

- Wooden Box Packaging: Suitable for larger shipments and ensures safe transportation.

- Carton Packaging: Ideal for smaller quantities, ensuring products are secure.

- Foam Fill Packaging: Provides additional protection during transit.

- Waterproof and Moisture-Proof Packaging: Keeps products dry and free from corrosion.

- Custom Packaging: We offer packaging solutions tailored to meet your specific needs.

- International Standard Packaging: All our packaging materials comply with international safety and handling standards.

|

|

|

|

|

|

|

|

Logistics

- Sea Freight: Ideal for large, bulk orders that require cost-effective shipping solutions.

- Air Freight: Fast and efficient, suitable for smaller shipments that require quick delivery.

- Land Freight: Available for regional shipments, ensuring timely delivery across land borders.

- Multimodal Transport: We offer flexible transportation solutions that combine sea, air, and land shipping.

- Courier Services: For smaller, urgent orders, we provide express courier delivery.

FAQs

- What is the minimum order quantity (MOQ)?

- The MOQ for zirconium wire is typically 10 kg, but we can accommodate smaller orders for custom projects.

- Can you provide product samples?

- Yes, samples are available upon request. Please contact us for more details.

- How long is your lead time?

- Standard lead time is 4-6 weeks, depending on the order size and customization requirements.

- What are the payment terms?

- We accept payments via T/T, L/C, and other standard international payment methods.

- Do you offer technical support?

- Yes, we provide comprehensive technical support, including product recommendations and after-sales service.

Call to Action - Contact Us

Are you looking for a reliable supplier of corrosion-resistant zirconium wire? At Shaanxi Peakrise Metal Co., Ltd., we are ready to provide you with high-quality products, tailored to your specific needs. For more information, contact us today at info@peakrisemetal.com. Let us help you with your next project and experience the best in non-ferrous metal manufacturing!

YOU MAY LIKE

-

VIEW MOREASTM B523 Zirconium Seamless Tube

VIEW MOREASTM B523 Zirconium Seamless Tube -

VIEW MOREPremium Zirconium Crucible for Lab Use

VIEW MOREPremium Zirconium Crucible for Lab Use -

VIEW MOREZirconium Welding Wire

VIEW MOREZirconium Welding Wire -

VIEW MOREUltra-Thin Zirconium Metal Foil

VIEW MOREUltra-Thin Zirconium Metal Foil -

VIEW MORECustom-Cut Zirconium Alloy Sheet

VIEW MORECustom-Cut Zirconium Alloy Sheet -

VIEW MOREAerospace Zirconium Rods

VIEW MOREAerospace Zirconium Rods -

VIEW MOREDouble threaded silicon carbon rod heating element

VIEW MOREDouble threaded silicon carbon rod heating element -

VIEW MOREU Shape MoSi2 Heating Elements For Muffle Furnace

VIEW MOREU Shape MoSi2 Heating Elements For Muffle Furnace