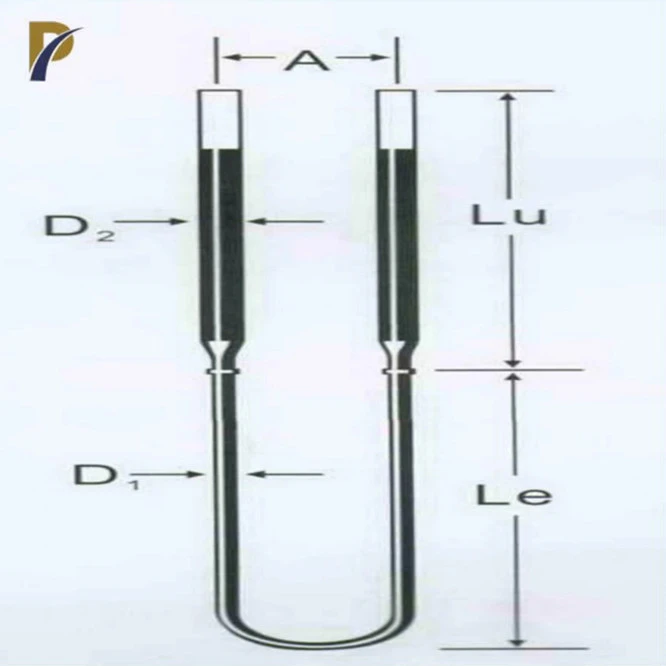

U Shape MoSi2 Heating Elements For Muffle Furnace

Type: U shape,Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Molybdenum silicide

Size: Φ3/6、Φ4/9、Φ6/12、Φ9/18、Φ12/24 Etc.

Density: 5.6~5.8g/cm3

Use Temperature: 1300~1800℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

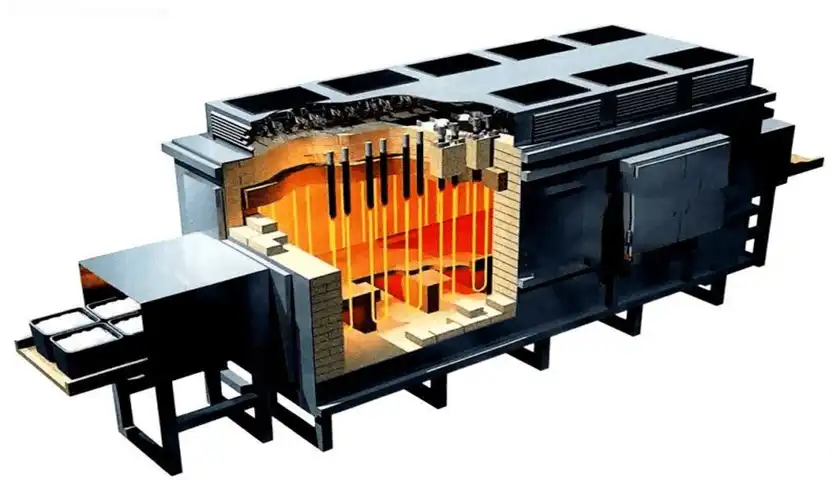

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

MoSi2 Heater Element Product Introduction

At Shaanxi Peakrise Metal Co., Ltd., we specialize in producing high-quality MoSi2 (Molybdenum Disilicide) heater elements, which are renowned for their exceptional performance in high-temperature applications. MoSi2 heater elements are widely used in industries that require temperatures up to 1800°C. These elements offer superior electrical conductivity and thermal resistance, making them ideal for applications in industrial furnaces, ceramics, and glass production. As a supplier with years of experience in the field of non-ferrous metals, including tungsten, molybdenum, and their alloys, we are committed to providing advanced heating solutions to meet the demands of our global customers.

Our MoSi2 heater elements are manufactured using high-purity molybdenum disilicide, which ensures long-lasting durability even in extreme temperature environments. Whether you are dealing with oxidizing, neutral, or reducing atmospheres, these heater elements maintain their structural integrity, making them a versatile choice for various industries. Shaanxi Peakrise Metal Co., Ltd. provides customized heating elements tailored to meet specific client needs. We pride ourselves on delivering OEM/ODM services to support unique application requirements.

Product Parameters

| Parameter | Value |

|---|---|

| Maximum Operating Temp | 1800°C |

| Density | 5.5–5.7 g/cm³ |

| Electrical Conductivity | 2.5–5 μΩ·cm |

| Melting Point | 2030°C |

| Thermal Expansion | 5.4 × 10⁻⁶/K |

| Model | Dimensions (mm) | Resistance (Ω) |

|---|---|---|

| U-shaped Element | 100 x 150 | 0.3–0.8 |

| W-shaped Element | 200 x 250 | 0.5–1.2 |

| Straight Element | 50 x 300 | 0.4–0.9 |

| Environmental Factor | Range |

|---|---|

| Oxidizing Atmosphere | 1200°C–1800°C |

| Neutral Atmosphere | 1000°C–1600°C |

| Reducing Atmosphere | 900°C–1400°C |

Physical and Mechanical Properties

MoSi2 heater elements exhibit excellent properties for high-temperature applications. They offer high resistance to oxidation, thanks to a protective layer of silicon dioxide (SiO2) that forms on the surface during operation. This protective layer regenerates over time, extending the element's lifespan. These elements also possess high tensile strength and are highly resistant to corrosion and thermal shock. With their low coefficient of thermal expansion, they maintain stability in varying temperature conditions, reducing the risk of breakage or deformation.

|

|

Product Functions

-

Efficient High-Temperature Heating

MoSi2 heater elements deliver consistent and stable heat in temperatures ranging from 1200°C to 1800°C, making them ideal for sintering processes, metal forging, and heat treatment in high-temperature furnaces. -

Oxidation Resistance

These elements form a silicon dioxide layer that protects against further oxidation, enabling extended service life even in extreme environments. -

Versatile Atmosphere Compatibility

MoSi2 heater elements can operate effectively in oxidizing, neutral, and reducing atmospheres, making them suitable for a variety of industrial applications. -

Energy Efficiency

Due to their high electrical conductivity, these elements consume less energy while providing powerful heat output, which is essential for energy-sensitive industries.

Product Applications

-

Industrial Furnaces

MoSi2 heater elements are widely used in electric furnaces for processes such as sintering, annealing, and melting. Their ability to withstand high temperatures makes them critical components in metal production and heat treatment. -

Ceramics and Glass Industry

These elements are ideal for ceramic firing and glass melting processes, where they help maintain uniform heat distribution and precise temperature control. -

Laboratory Equipment

In research environments, MoSi2 elements are used in thermal analysis instruments and high-temperature test equipment for material testing and development. -

Semiconductor Manufacturing

MoSi2 heater elements play a crucial role in semiconductor processing, particularly in furnaces used for the diffusion and annealing of semiconductor materials.

|

|

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., our MoSi2 heater elements are manufactured following a precise and controlled process to ensure high quality:

-

Material Selection

We use high-purity molybdenum disilicide powders, ensuring optimal performance in terms of both electrical conductivity and temperature resistance. -

Powder Processing

The raw materials undergo fine grinding and homogeneous mixing, followed by high-temperature sintering in an intermediate frequency furnace to achieve desired structural integrity. -

Shaping and Forming

Using advanced CNC technology, we accurately shape the MoSi2 elements into U, W, and straight configurations, which are then inspected for dimensional accuracy. -

Quality Control and Testing

Each batch undergoes stringent testing to ensure consistency in resistance, mechanical strength, and overall performance. The elements are tested in simulated operational conditions to guarantee reliability.

Our Factory

Our factory is equipped with state-of-the-art production equipment, including vacuum arc melting furnaces, laser cutters, and plasma electron beam melting furnaces. This allows us to produce high-quality MoSi2 heater elements that meet the stringent demands of global markets. We maintain a large inventory of raw materials, which ensures prompt production and delivery to our clients worldwide.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Crates

Heavy-duty wooden crates are used for secure transportation of large elements. - Cardboard Packaging

Lightweight elements are packaged in reinforced cardboard boxes. - Foam Padding

To prevent damage, we use foam-filled packaging for additional protection. - Waterproof and Moisture-Proof Packaging

Ensures that elements are protected from environmental factors during transit.

Logistics Options

- Sea Freight

Cost-effective for bulk orders. - Air Freight

Suitable for time-sensitive deliveries. - Land Transport

Reliable and fast for regional shipments. - Multimodal Transport

Combines multiple forms of transport for optimized shipping. - Courier Services

For small, urgent orders, we offer door-to-door delivery via express courier services.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Extensive Experience

Over a decade of experience in non-ferrous metal production, serving clients globally. - Advanced Manufacturing

Equipped with cutting-edge production facilities to ensure high product quality. - Comprehensive Services

From material research and development to product testing, we offer a full range of services. - Global Reach

Products exported to over 20 countries with a strong reputation for reliability and quality. - Tailored Solutions

We provide OEM/ODM services, allowing clients to customize products to meet their unique requirements.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. is dedicated to offering OEM and ODM services. We can produce MoSi2 heater elements according to your specific design, dimension, and technical specifications. Our team of experts works closely with clients to ensure that the final product meets the required standards, and we welcome inquiries from businesses looking for customized heating solutions.

-

What is the maximum temperature the MoSi2 heater element can withstand?

The maximum temperature is 1800°C, making it ideal for high-temperature applications. -

Can MoSi2 heater elements be customized?

Yes, we offer OEM/ODM services to tailor the elements according to your specific requirements. -

How long do MoSi2 heater elements last?

With proper use, these elements can last up to 10,000 hours, depending on the application and atmosphere. -

What packaging options are available?

We offer a variety of packaging options, including wooden crates, foam-filled boxes, and waterproof packaging. -

How do I order a custom-designed MoSi2 heater element?

Contact us directly at info@peakrisemetal.com to discuss your specifications, and our team will assist you with the process.

Contact Us

For all your MoSi2 heater element needs, Shaanxi Peakrise Metal Co., Ltd. is here to provide high-quality products and excellent customer service. Reach out to us at info@peakrisemetal.com for more information or to place an order. We welcome global buyers to partner with us for reliable and efficient heating solutions.