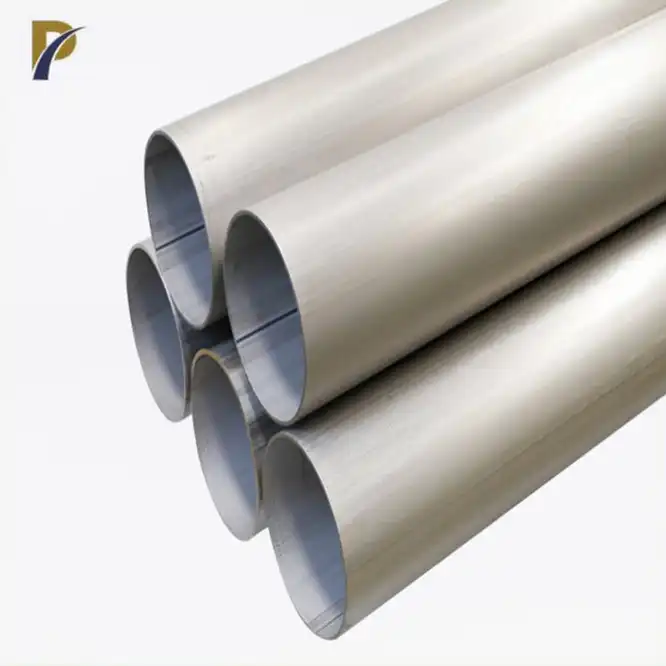

Zirconium Welded Tubing Supply

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Welded Tubing Supply by Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. proudly presents its premium Zirconium Welded Tubing, a highly specialized product designed for demanding applications in the chemical, nuclear, and aerospace industries. Zirconium is renowned for its excellent corrosion resistance, particularly in harsh environments such as acidic and high-temperature conditions. The welded tubing we provide ensures maximum durability, high precision, and top-tier performance in challenging operational scenarios.

Zirconium welded tubing is essential for industries requiring high levels of safety and efficiency. Our tubing is manufactured using advanced technologies that enhance its resistance to corrosion and heat, making it ideal for heat exchangers, reactors, and chemical processing equipment. As a trusted supplier, Shaanxi Peakrise Metal Co., Ltd. has been at the forefront of Zirconium Welded Tubing Supply for years, delivering quality that exceeds industry standards. Our vast experience in the production of non-ferrous metals ensures that our clients receive reliable, high-performance materials tailored to their specific needs.

Our company is recognized worldwide for providing high-quality non-ferrous metal products, and we have built a reputation for excellence. Over the past decade, we have expanded our global market reach, providing Zirconium welded tubing to customers in the United States, Europe, South Korea, and other regions. Our goal is to deliver superior products that meet your precise specifications while offering competitive pricing and exceptional customer service.

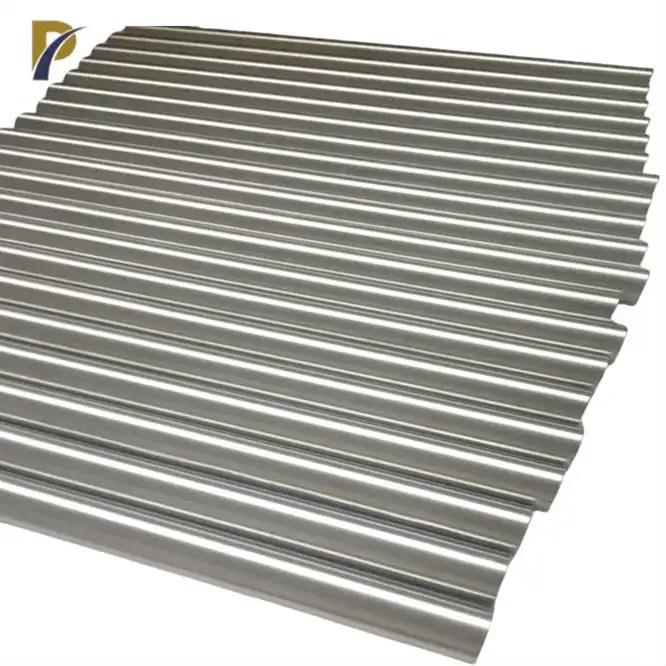

Product Specifications

Material:zirconium

Grade:Zr2 Zr4 Zr702 Zr705 Zr60804 Zr60001 Zr60901

Wall thickness:0.3mm-120mm,customer customize

Length:customer customize

Certificate:ISO9001:2008

Density:6.51g/cm3

Standard: ASTM B523 ASTM B658,ASTM B353

Surface treatment: anodizing, polishing, powder coating, electrophoresis, sandblasting, coating, etc.

Inspection:Eddy current flaw detection,Hydrostaticte

| Mechanical Properties | Zr 702 | Zr 705 |

|---|---|---|

| Tensile Strength | 380 MPa | 650 MPa |

| Yield Strength | 207 MPa | 450 MPa |

| Elongation | 30% | 25% |

| Hardness (HV) | 120 | 210 |

| Chemical Composition | Zr 702 | Zr 705 |

|---|---|---|

| Zirconium (Zr) | ≥ 99.2% | ≥ 95.5% |

| Oxygen (O) | ≤ 0.16% | ≤ 0.16% |

| Hafnium (Hf) | ≤ 4.5% | ≤ 4.5% |

|

|

Product Functions

- Corrosion Protection: Zirconium welded tubing provides superior resistance against corrosion, particularly in aggressive environments with acidic and alkaline materials.

- High Thermal Stability: This tubing performs reliably under extreme heat, making it suitable for high-temperature industrial processes.

- Durability: Its mechanical strength and resistance to wear make zirconium tubing a long-lasting solution in various industries.

- Low Toxicity: Zirconium is biocompatible and non-toxic, which is crucial for its applications in medical devices and nuclear reactors.

Product Applications

- Chemical Processing: Zirconium welded tubing is widely used in heat exchangers, condensers, and piping systems where high corrosion resistance is required.

- Nuclear Industry: Thanks to its low absorption of thermal neutrons, zirconium tubing is a key component in nuclear reactors, where it is used in cladding and structural components.

- Aerospace: In aerospace engineering, zirconium’s heat resistance and durability make it an excellent material for critical parts such as fuel lines and hydraulic systems.

- Medical Devices: Zirconium is non-toxic and highly resistant to body fluids, making it an ideal material for implants and surgical instruments.

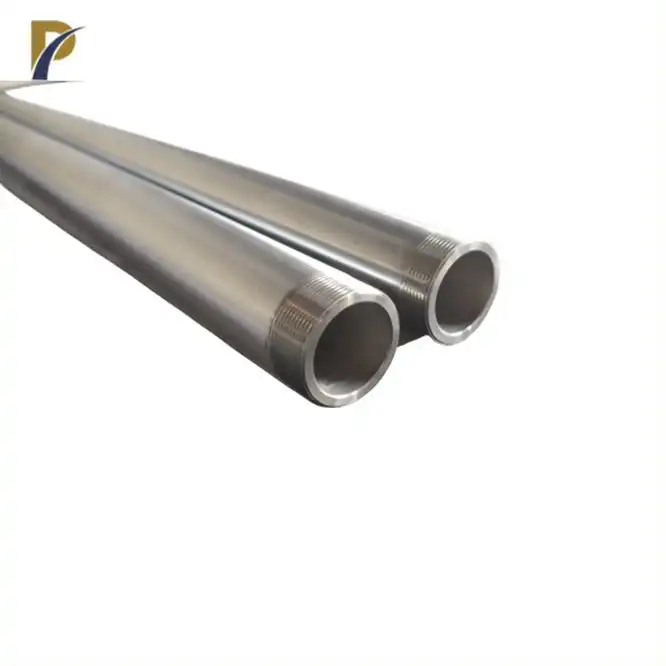

Manufacturing Process

Our Zirconium Welded Tubing is produced using a strict and efficient manufacturing process to ensure the highest quality:

- Raw Material Selection: High-grade zirconium (Zr 702, Zr 704, or Zr 705) is carefully chosen for its purity and performance.

- Forming: The raw material is cold rolled and shaped into tubes of the desired diameter and wall thickness.

- Welding: Advanced plasma welding techniques are employed to create seamless joints with minimal defects.

- Annealing: The tubes are heat-treated in a vacuum furnace to ensure uniformity in structure and strength.

- Surface Finishing: The final product is polished or pickled to achieve a smooth surface finish, enhancing its corrosion resistance.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Industry Expertise: With over a decade of experience, Shaanxi Peakrise Metal Co., Ltd. specializes in manufacturing and supplying high-quality non-ferrous metal products.

- Comprehensive Services: We provide a full range of services, including material development, product testing, and stock inventory.

- Global Reach: Our products are trusted by clients in Taiwan, Ukraine, South Korea, the U.S., Australia, and more.

- Advanced Equipment: We use state-of-the-art equipment, including vacuum arc melting furnaces, plasma electron beam melting, CNC machines, and more.

- Quality Assurance: Rigorous quality control ensures that every product meets or exceeds international standards.

|

|

|

|

|

|

|

|

|

|

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we support comprehensive OEM/ODM services to meet your specific needs. Whether you require customized dimensions, specific grades, or surface finishes, we can tailor our Zirconium Welded Tubing to your exact specifications. Our experienced team will work closely with you to ensure your product meets your industry standards and project requirements.

|

|

FAQs

-

What grades of zirconium are available?

We offer Zr 702, Zr 704, and Zr 705 grades, depending on your application needs. -

Can the tubing be customized?

Yes, we provide customization options, including different diameters, wall thicknesses, and lengths. -

What is the lead time for production?

Lead times vary depending on order size, but typically range from 4 to 6 weeks. -

Is your tubing suitable for high-temperature environments?

Absolutely, our zirconium tubing is designed to withstand extreme temperatures and corrosive environments. -

Do you ship internationally?

Yes, we offer global shipping via sea, air, or land transport.

Packaging and Logistics

- Packaging:

- Wooden crates for heavy loads

- Foam and cardboard box for smaller, delicate shipments

- Waterproof and moisture-proof protective layers

- Custom packaging according to client requirements

- Logistics:

- Sea Freight: Ideal for bulk orders with extended lead times.

- Air Freight: Faster shipping for urgent orders.

- Land Transport: Available for regional deliveries.

- Multimodal Shipping: Combining different transport modes for efficiency.

- Express Courier: For small, time-sensitive orders.

Call to Action: Contact Us

Looking for a reliable supplier of Zirconium Welded Tubing? Shaanxi Peakrise Metal Co., Ltd. is here to meet your needs with high-quality products and exceptional customer service. Contact us today to discuss your project requirements and request a quote. We look forward to collaborating with you!

Email us at info@peakrisemetal.com or fill out our contact form on the website to get started.