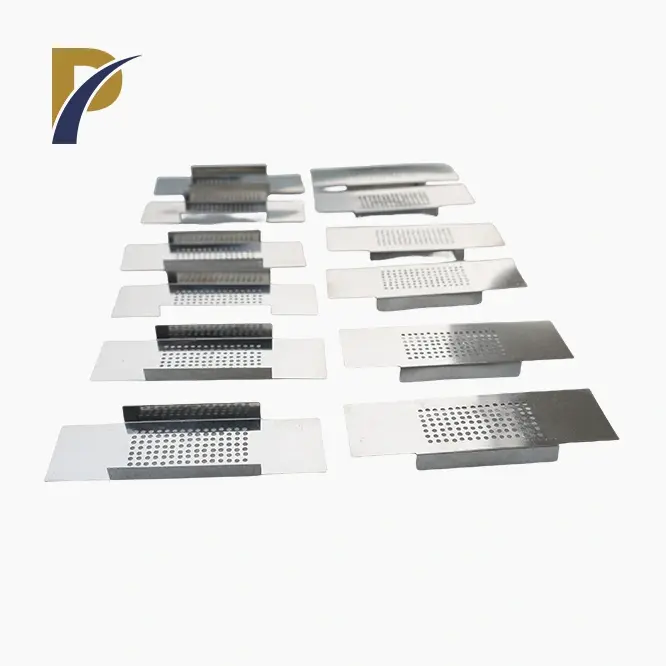

Zirconium Engineered Components

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Engineered Components - Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Zirconium Engineered Components are increasingly critical in industries requiring high performance under extreme conditions. Known for its exceptional resistance to corrosion, high melting point, and strong mechanical properties, zirconium is a material of choice for a range of demanding applications. At Shaanxi Peakrise Metal Co., Ltd., we specialize in manufacturing premium zirconium engineered components tailored to the stringent needs of industries such as chemical processing, aerospace, nuclear energy, and more.

As a trusted supplier of zirconium products, Shaanxi Peakrise Metal has over a decade of experience in the production of non-ferrous metals. Our zirconium engineered components are produced to meet international standards, ensuring that customers receive reliable, high-quality materials for their specific applications. We combine state-of-the-art equipment and a dedicated team of engineers to deliver solutions that excel in challenging environments, making us a leading choice for businesses across the globe.

Product Specifications

| Property | Zirconium 702 | Zirconium 705 | Zirconium Alloy Custom |

|---|---|---|---|

| Purity (%) | ≥ 99.2 | ≥ 98.0 | Customizable |

| Tensile Strength (MPa) | 379 | 550 | Customizable |

| Density (g/cm³) | 6.51 | 6.5 | Customizable |

| Melting Point (°C) | 1855 | 1870 | Customizable |

| Yield Strength (MPa) | 207 | 450 | Customizable |

| Elongation (%) | 16 | 20 | Customizable |

Our zirconium engineered components are produced using strict quality control measures, ensuring dimensional accuracy, consistent material properties, and long-lasting performance.

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Physical and Chemical Properties

- Corrosion Resistance: Zirconium is renowned for its extraordinary resistance to corrosion, especially in aggressive environments such as acidic solutions and high-temperature atmospheres. This makes it ideal for chemical processing equipment.

- High Melting Point: With a melting point of 1855°C, zirconium components can withstand extreme heat, making them highly suitable for use in high-temperature processes.

- Low Thermal Neutron Absorption: Zirconium's unique property of low neutron absorption makes it indispensable in nuclear reactors, where it serves as a cladding material for fuel rods.

- Strength and Ductility: Zirconium alloys, such as Zirconium 702 and 705, offer an excellent combination of strength and ductility, providing both robustness and flexibility under mechanical stress.

Product Applications

Zirconium engineered components find widespread use in various industries due to their unique properties. Here are some key applications:

- Chemical Processing: Zirconium components are commonly used in reactors, heat exchangers, and piping systems in the chemical industry. Their resistance to acids and corrosion ensures long-term reliability.

- Nuclear Industry: Due to its low neutron absorption and high corrosion resistance, zirconium alloys are essential in nuclear reactors as cladding for fuel rods and other critical components.

- Aerospace: The aerospace industry leverages zirconium’s high strength-to-weight ratio and corrosion resistance for engine components, structural elements, and aerospace fittings.

- Medical Devices: In the medical field, zirconium is used to manufacture surgical instruments, dental implants, and prosthetics due to its biocompatibility and non-reactive properties.

- Marine Environments: Zirconium’s resistance to saltwater corrosion makes it ideal for use in marine engineering, including shipbuilding and offshore oil exploration.

|

|

|

|

|

|

|

|

|

Product Specifications

| Parameter | Value | Units |

|---|---|---|

| Zirconium Purity | 99.95% | |

| Density | 6.51 | g/cm³ |

| Melting Point | 1855 | °C |

| Tensile Strength | 330 - 680 | MPa |

| Thermal Conductivity | 22.7 | W/m·K |

| Maximum Working Temperature | 850 | °C |

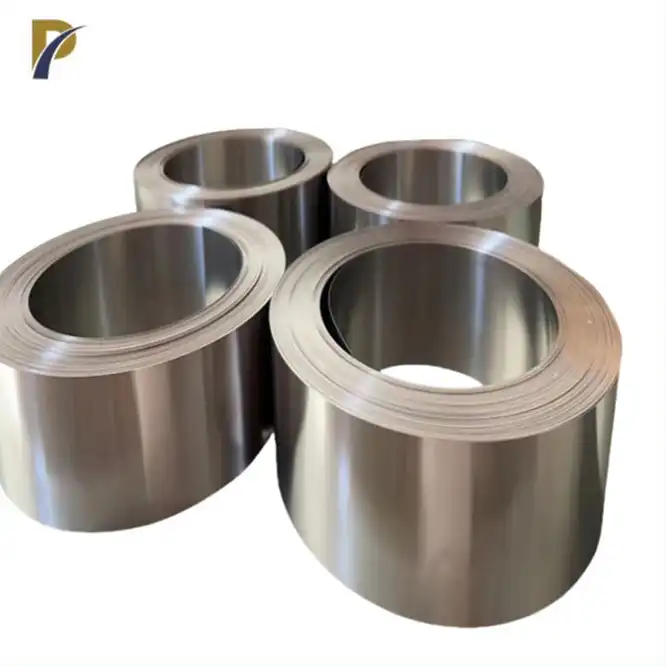

Manufacturing Process

Our zirconium engineered components are produced through a series of precise manufacturing steps, ensuring optimal quality and performance:

- Material Selection: High-grade zirconium raw materials are sourced from trusted suppliers.

- Melting: Zirconium is melted in our vacuum arc melting furnace to ensure purity and consistent material properties.

- Forging and Rolling: The molten material is then forged and rolled into desired shapes and sizes using advanced rolling mills.

- Heat Treatment: Components undergo heat treatment in our vacuum annealing furnaces to enhance their mechanical properties and corrosion resistance.

- Machining and Finishing: Precision machining ensures that each component meets exact specifications, with final finishing to achieve a smooth surface.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Over a Decade of Experience: With over ten years of experience in non-ferrous metal production, Shaanxi Peakrise Metal Co., Ltd. is a leader in delivering high-quality zirconium components.

- State-of-the-Art Equipment: Our factory is equipped with cutting-edge machinery, including vacuum arc melting furnaces, CNC machines, and advanced heat treatment facilities, ensuring the best quality in every product.

- Global Reach: Our products are exported to over 20 countries, including the USA, Germany, and Australia, with a strong reputation for reliability and quality.

- Comprehensive Quality Control: Every component is subject to rigorous testing, including material composition analysis, mechanical property tests, and dimensional accuracy checks.

- Customized Solutions: We offer OEM services, allowing you to customize the design, material composition, and specifications of your zirconium components to meet your exact requirements.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers tailored OEM services to meet your specific needs. We provide:

- Custom material compositions based on your industry requirements.

- Custom dimensions and design modifications to suit your application.

- Private labeling and packaging options.

- Flexible production schedules to accommodate your delivery timelines.

|

|

Packaging

We ensure safe and secure packaging to protect your zirconium components during transportation:

- Wooden Crate Packaging: Ideal for heavy and bulk products, providing robust protection.

- Carton Box Packaging: Suitable for smaller components with additional cushioning.

- Foam Padding: Ensures shock resistance during shipping.

- Waterproof and Moisture-Proof Packaging: Safeguards products from environmental damage.

- Custom Packaging: Tailored to meet the unique needs of our customers.

- International Standard Packaging: Complies with global shipping regulations.

Logistics

We provide reliable and efficient logistics services to ensure timely delivery worldwide:

- Sea Freight: Cost-effective for bulk shipments.

- Air Freight: Fast and efficient for urgent deliveries.

- Land Transport: Available for regional customers.

- Multimodal Transport: Combining sea, air, and land transport for the best solution.

- Express Courier Services: For small, urgent orders.

|

|

|

|

|

|

|

|

|

|

FAQs:

- What is the minimum order quantity?

- Our minimum order quantity depends on the specific product and customization requirements. Please contact us for more details.

- Can you provide custom sizes?

- Yes, we offer OEM services and can produce zirconium components in custom sizes according to your specifications.

- What is the typical lead time for orders?

- Lead times vary depending on the product and order size but generally range from 4-8 weeks.

- Do you offer sample products?

- Yes, we can provide samples for testing and evaluation. Contact us to discuss your requirements.

- What industries do your zirconium components serve?

- Our zirconium components are widely used in industries such as chemical processing, aerospace, nuclear energy, and medical devices.

Call to Action - Contact Us

Are you ready to elevate your projects with high-quality zirconium engineered components? Contact Shaanxi Peakrise Metal Co., Ltd. today to discuss your requirements and how we can support your business with reliable, customized solutions. Email us at info@peakrisemetal.com for more information. Let’s work together to bring your projects to new heights!

YOU MAY LIKE

-

VIEW MORE50ml 1mm thickness pure zirconium crucible

VIEW MORE50ml 1mm thickness pure zirconium crucible -

VIEW MOREU type sic heater element

VIEW MOREU type sic heater element -

VIEW MOREsilicon carbide sic heating element

VIEW MOREsilicon carbide sic heating element -

VIEW MOREsingle spiral sic heater element

VIEW MOREsingle spiral sic heater element -

VIEW MOREtantalum foil 0.1mm

VIEW MOREtantalum foil 0.1mm -

VIEW MOREtitanium wire for jewelry

VIEW MOREtitanium wire for jewelry -

VIEW MOREtitanium pipe and fittings

VIEW MOREtitanium pipe and fittings -

VIEW MOREtitanium wedding rings

VIEW MOREtitanium wedding rings