silicon carbide sic heating element

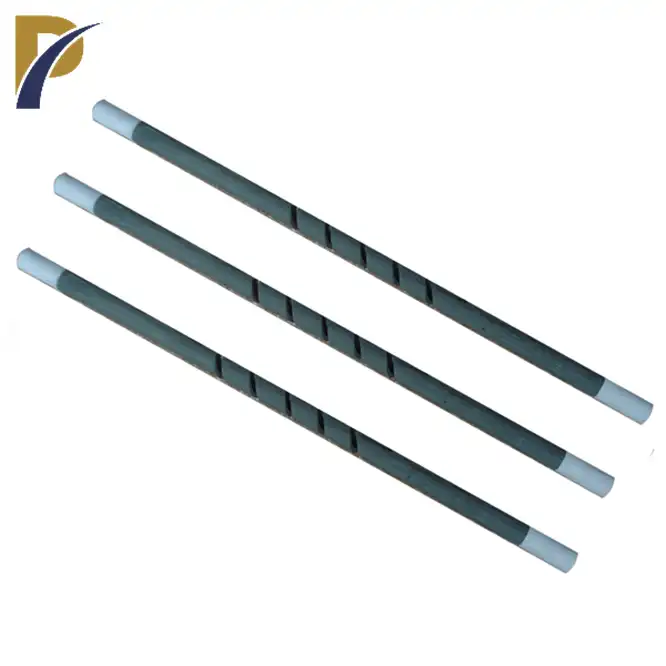

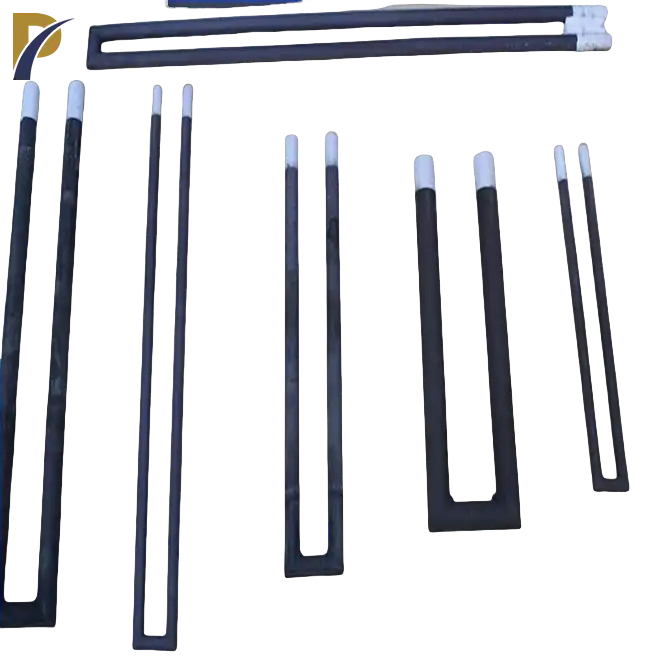

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

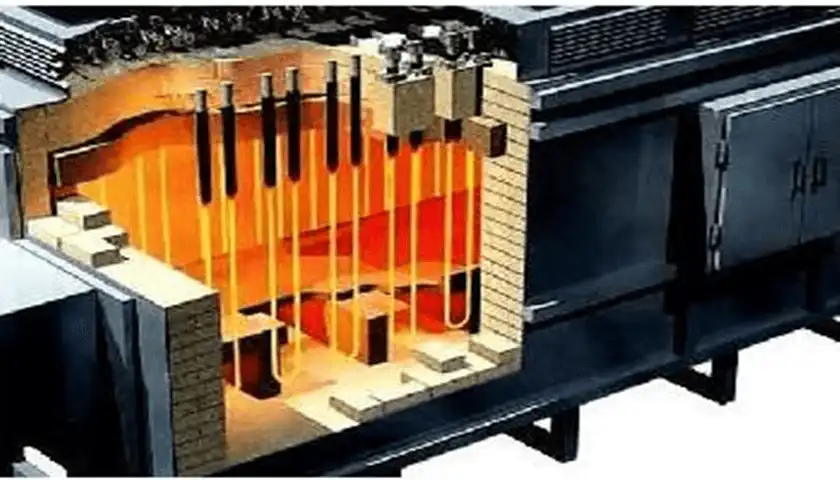

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

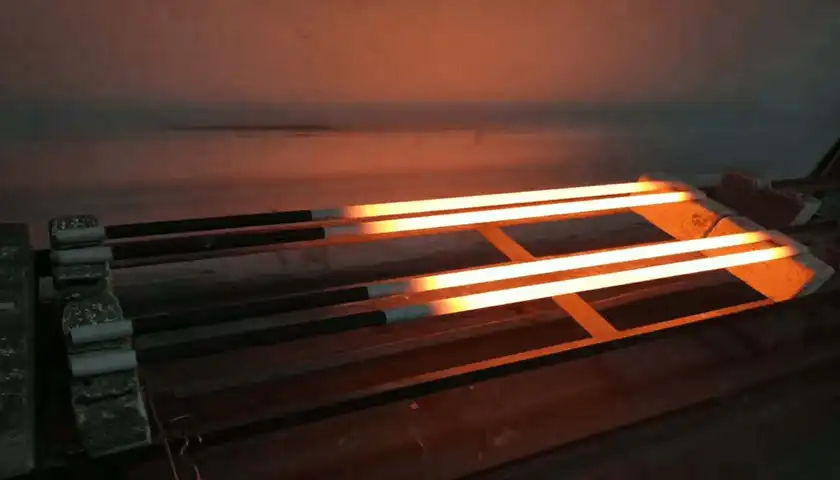

Silicon Carbide (SiC) Heating Element - Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is proud to offer high-quality silicon carbide (SiC) heating elements, designed for various industrial heating applications. These elements are widely recognized in the industry for their exceptional performance under extreme conditions, offering stability, efficiency, and durability. As a trusted supplier, we specialize in providing SiC heating elements that are suitable for both domestic and international markets. With extensive experience in manufacturing and exporting high-performance materials, we ensure that our products meet stringent quality standards, making them ideal for industrial furnaces, kilns, and other high-temperature heating systems.

Our SiC heating elements are available in a variety of shapes and sizes, designed to meet the specific requirements of industries such as metallurgy, ceramics, glass, and chemical processing. These heating elements have become the preferred choice for industries due to their high thermal conductivity, corrosion resistance, and ability to maintain structural integrity at high temperatures. With over a decade of experience in the global market, Shaanxi Peakrise Metal Co., Ltd. continues to expand its product line, offering customizable solutions and high-quality products to meet the ever-evolving needs of our customers.

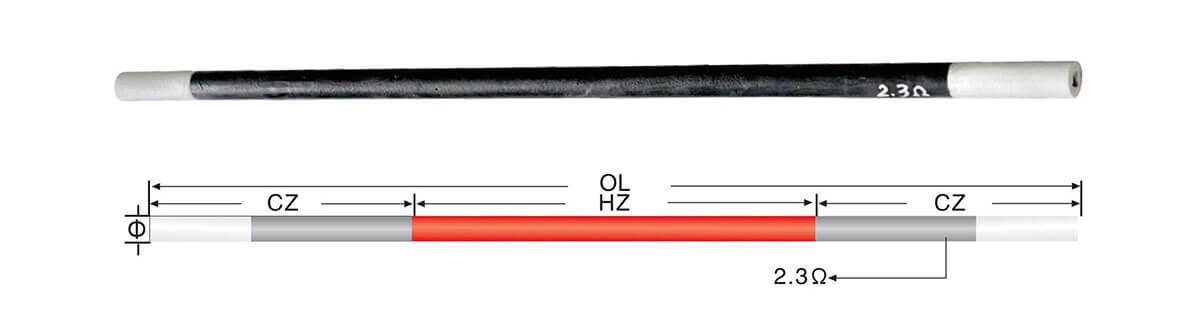

The straight silicon carbon rod is welded by 3 sections, with the middle section being the heating section and both ends being the cold ends. The maximum operating temperature is 1500℃.

| Diameter OD(mm) | 10 | 12 | 14 | 16 | 18 | 20 | 25 | 30 | 32 | 35 | 38 | 40 | 45 | 50 | 55 | 60 |

| Hotzone HZ (mm) | 350 | 500 | 600 | 600 | 800 | 900 | 1100 | 1300 | 1300 | 1450 | 2000 | 2000 | 2400 | 2400 | 2400 | 2400 |

| Overall length OL (mm) | 650 | 950 | 1100 | 1300 | 1500 | 1600 | 1800 | 2100 | 2500 | 2500 | 3000 | 3800 | 3800 | 3800 | 3800 | 3800 |

|

|

Physical and Mechanical Properties

1. Silicon carbon rods have high mechanical strength and bending strength up to 100-120MPa

2. High surface temperature can reach 1500 degrees

3. High infrared radiation rate, equal diameter silicon carbon rods are 5-10 times that of ordinary nickel-chromium wires

4. Long service life, simple installation and maintenance

5. Silicon carbon rods have strong oxidation resistance, strong corrosion resistance, and excellent heat shock resistance

Product Functions

- High-Temperature Heating: SiC heating elements are designed to operate in temperatures as high as 1600°C, making them ideal for industrial processes that require extreme heat.

- Energy Efficiency: These elements exhibit high electrical efficiency, converting a large percentage of electrical energy into heat with minimal loss.

- Consistent Heat Distribution: SiC heating elements ensure even heat distribution across the heating zone, improving process reliability and product quality.

- Longevity: The chemical and mechanical stability of these elements translates into a longer service life, reducing the frequency of replacements.

- Customizable Options: Shaanxi Peakrise Metal Co., Ltd. offers a range of customizable SiC heating elements to meet specific size, power, and temperature requirements.

|

|

Product Applications

Silicon carbon rod heating elements are commonly used in rare earth phosphors, electronics, magnetic materials, powder metallurgy, precision casting and other industries. They are used as heating elements for push plate furnaces, mesh belt furnaces, trolley furnaces, and box furnaces.

|

|

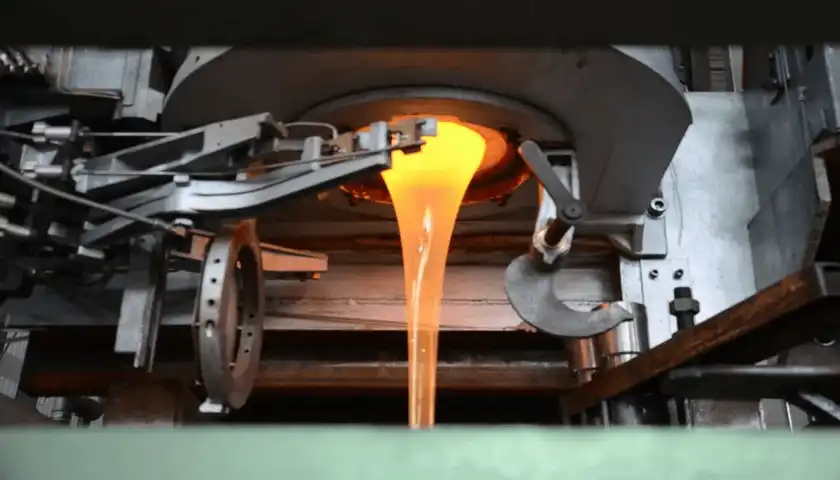

Product Process and Production Flow

Our production process follows stringent quality control measures to ensure the highest standard of silicon carbide heating elements. From material selection to the final product testing, every step is carefully monitored.

- Material Selection: High-purity silicon carbide materials are sourced to ensure optimal performance.

- Forming and Sintering: The elements are formed using advanced techniques and sintered at high temperatures to achieve the desired properties.

- Machining: After sintering, the elements are precision-machined to meet the specific dimensional requirements of each customer.

- Quality Testing: Every batch of elements undergoes rigorous electrical, mechanical, and thermal testing to ensure they meet our strict standards.

- Packaging: The finished products are carefully packaged to prevent damage during transit.

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is equipped with state-of-the-art production facilities, including vacuum furnaces, plasma cutting equipment, and CNC machines. Our factory covers a wide range of production capabilities, allowing us to manufacture both standard and customized SiC heating elements. We maintain a complete inventory of raw materials and finished products to ensure timely delivery to our customers.

Logistics and Packaging

- Packaging:

- Wooden crates for maximum protection during shipping.

- Foam-filled boxes for cushioning and shock absorption.

- Waterproof and moisture-resistant packaging for sensitive environments.

- Custom packaging available based on client specifications.

|

|

2. Logistics:

Sea freight for bulk international orders.

Air freight for expedited shipping needs.

Land transport for domestic and neighboring country deliveries.

Multimodal transport solutions for complex logistics requirements.

Express courier services for small or urgent orders.

|

Why Choose Us?

- Experience and Expertise: With over a decade in the field, Shaanxi Peakrise Metal Co., Ltd. is a trusted name in the non-ferrous metals industry, offering unparalleled expertise in SiC heating elements.

- Quality Assurance: We are committed to providing high-quality products that meet international standards, backed by our ISO9001 certification.

- Advanced Technology: Our production process incorporates the latest in material science and manufacturing technologies, ensuring superior products.

- Customization: We offer tailored solutions to meet the unique needs of our customers, from small-scale projects to large industrial orders.

- Global Reach: Our products are exported worldwide, with a growing customer base in the United States, Europe, and Asia.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers flexible OEM and ODM services for SiC heating elements. Whether you need custom sizes, specific electrical properties, or unique shapes, our team can work with you to design the perfect solution. Our in-house R&D team ensures that each custom order meets the highest standards of quality and performance.

FAQ

- What is the maximum operating temperature of SiC heating elements?

- Our SiC heating elements can operate at temperatures up to 1600°C.

- Can these elements be customized to specific dimensions?

- Yes, we offer full customization options to meet the needs of your specific application.

- What industries commonly use SiC heating elements?

- These elements are widely used in industries such as metallurgy, ceramics, glass, and chemical processing.

- What is the typical lifespan of an SiC heating element?

- With proper usage, our SiC heating elements can last several years, depending on operating conditions.

- Do you offer technical support for installation?

- Yes, we provide comprehensive support for installation and maintenance of our products.

Contact Us

Interested in our SiC heating elements? Contact us today to discuss how we can meet your heating element needs. We welcome global purchasers to partner with Shaanxi Peakrise Metal Co., Ltd. for high-quality, reliable products. Reach us at info@peakrisemetal.com. We look forward to working with you!