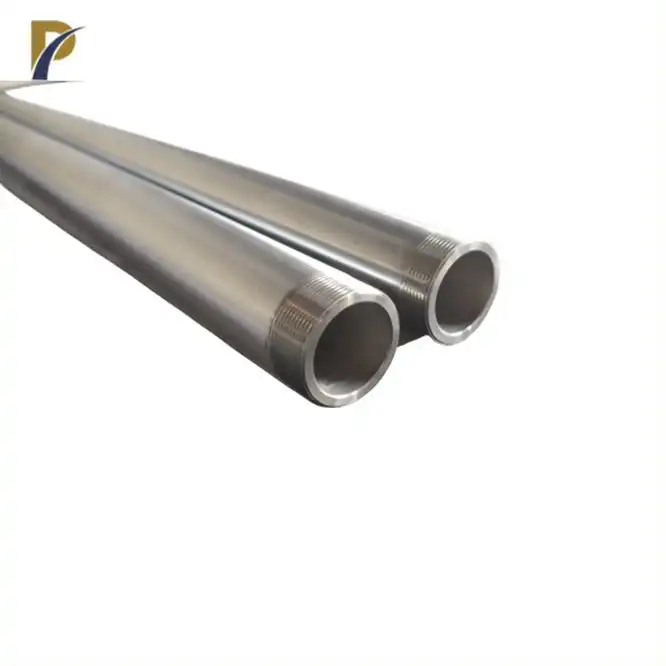

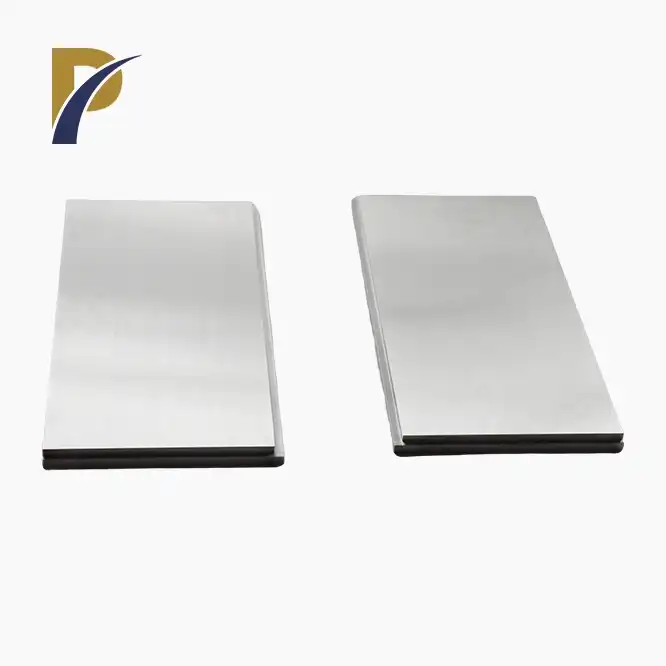

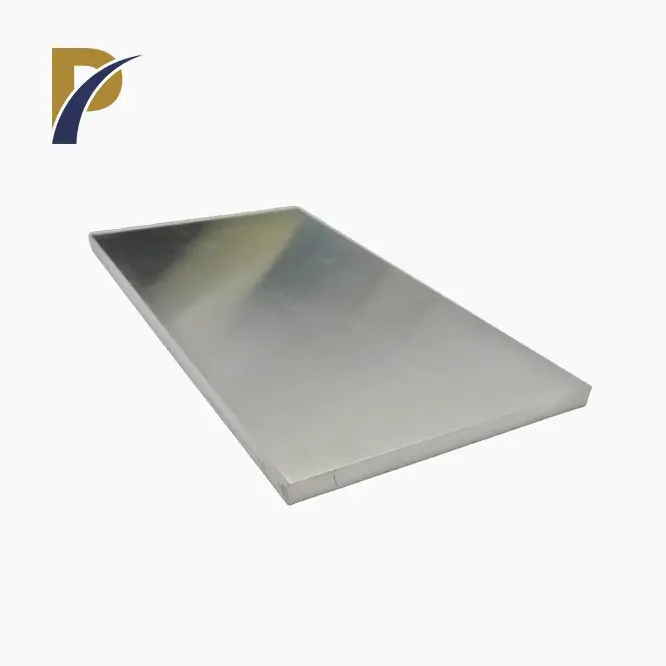

Precision Zirconium Metal Parts

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Precision Zirconium Metal Parts – Shaanxi Peakrise Metal Co., Ltd.

At Shaanxi Peakrise Metal Co., Ltd., we specialize in the manufacturing and supply of precision zirconium metal parts, serving industries worldwide. Zirconium is a highly valuable metal in a wide array of industries due to its outstanding corrosion resistance, thermal stability, and mechanical strength. Whether it's for aerospace, medical devices, nuclear power generation, or chemical processing, zirconium metal parts are trusted for their ability to perform in the most demanding environments.

As a leading supplier of precision zirconium metal parts, Shaanxi Peakrise Metal Co., Ltd. is committed to providing high-quality, tailor-made solutions for our customers. With decades of experience in non-ferrous metals production and global distribution, we understand the critical nature of high-performance materials. Our precision zirconium parts are crafted to meet the stringent specifications required in today's competitive industries, ensuring reliable performance and longevity.

Our factory is equipped with state-of-the-art production equipment and operated by a team of experienced professionals. We employ advanced manufacturing processes to ensure precision, consistency, and quality in every part we deliver. Over the years, we’ve established ourselves as a trusted partner in the production and supply of zirconium metal parts, building long-term relationships with clients across the globe.

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

Product Specifications

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| Parameter | Value | Unit |

|---|---|---|

| Electrical Resistivity | 40 | µΩ·cm |

| Thermal Conductivity | 22 | W/m·K |

| Coefficient of Expansion | 5.7 x 10⁻⁶ | /K |

| Elastic Modulus | 99 | GPa |

| Yield Strength | 200 | MPa |

| Parameter | Value | Unit |

|---|---|---|

| Maximum Operating Temp. | 650 | °C |

| Oxidation Resistance | Excellent | - |

| Surface Finish | Customizable | - |

| Dimension Tolerance | ±0.01 | mm |

| Manufacturing Process | CNC Machining, Casting | - |

Physical and Chemical Properties of Zirconium Metal

Zirconium is a lustrous, greyish-white metal with remarkable resistance to corrosion. Its strength, ductility, and ability to withstand high temperatures make it an ideal material for critical applications. Chemically, zirconium is resistant to most acids and alkalis, as well as seawater, which makes it a preferred choice in aggressive environments. Furthermore, zirconium has a high melting point of 1855°C and excellent thermal conductivity, making it suitable for use in heat exchangers and other high-temperature applications.

Product Features

-

Corrosion Resistance: Zirconium metal parts exhibit extraordinary resistance to corrosion, particularly in acidic and alkaline environments. This property makes it an excellent choice for applications in chemical processing and marine industries.

-

High Strength-to-Weight Ratio: Zirconium provides high mechanical strength while maintaining a relatively low density, making it ideal for aerospace and medical device applications where weight reduction is critical.

-

Thermal Stability: With its high melting point and ability to retain structural integrity at elevated temperatures, zirconium parts are suitable for high-temperature applications, such as nuclear reactors and furnaces.

-

Biocompatibility: Zirconium is known for its biocompatibility, making it safe for use in medical implants and surgical tools.

-

Customizability: At Shaanxi Peakrise Metal Co., Ltd., we offer precision machining capabilities that allow us to deliver zirconium parts with tight tolerances and custom specifications, meeting the exact needs of our clients.

|

|

|

Product Applications

-

Aerospace: Precision zirconium parts are used in the aerospace industry for components exposed to extreme temperatures and corrosive environments. Their lightweight nature and high strength-to-weight ratio make them a preferred material for structural applications.

-

Nuclear Energy: Due to zirconium’s low neutron absorption rate and high resistance to radiation damage, it is extensively used in nuclear reactors for fuel cladding and other critical components.

-

Medical Devices: The biocompatibility of zirconium makes it suitable for medical implants, surgical instruments, and dental devices. It is non-reactive in the human body, ensuring safety and longevity.

-

Chemical Processing: Zirconium is highly resistant to corrosion in harsh chemical environments, making it ideal for use in the production of heat exchangers, pumps, and valves for the chemical and petrochemical industries.

-

Automotive: In high-performance automotive applications, zirconium is used in parts that require high thermal stability and corrosion resistance, such as exhaust systems and brake components.

|

|

Manufacturing Process

At Shaanxi Peakrise Metal Co., Ltd., we utilize advanced production processes to manufacture precision zirconium metal parts. Our process includes:

-

Raw Material Selection: We source the highest quality zirconium, ensuring that it meets the necessary purity standards.

-

Melting: Using vacuum arc melting and electron beam melting techniques, we produce zirconium ingots that are free from impurities.

-

Machining: Our CNC machines are capable of achieving tight tolerances, ensuring precision in every part we manufacture.

-

Finishing: Depending on customer requirements, we offer various surface finishes, including polishing, sandblasting, and anodizing.

-

Quality Control: All zirconium parts undergo rigorous testing for mechanical properties, chemical composition, and dimensional accuracy.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

-

Expertise: With over a decade of experience in the non-ferrous metals industry, we have the technical knowledge to deliver high-quality zirconium metal parts.

-

Advanced Equipment: Our factory is equipped with state-of-the-art production equipment, enabling us to handle complex manufacturing processes.

-

Global Presence: We have established long-term relationships with customers in more than 10 countries, including the USA, Germany, and South Korea.

-

Custom Solutions: We offer OEM/ODM services to meet the specific needs of our customers, ensuring that every part we deliver matches their exact specifications.

-

Reliable Quality: All of our products are tested to ensure compliance with international standards, providing customers with reliable and high-performance zirconium parts.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we understand that every customer has unique requirements. That’s why we offer a full range of OEM/ODM services. Whether you need custom dimensions, surface treatments, or specific material properties, our team can work with you to develop the ideal solution for your application.

|

|

FAQ

-

What is the lead time for zirconium metal parts?

The lead time depends on the complexity of the order and the quantity required. Generally, it takes 4-6 weeks for production and delivery. -

What are the minimum order quantities (MOQ)?

Our MOQ varies depending on the specific product and customer requirements. For most zirconium parts, the MOQ starts at 10 pieces. -

Do you provide samples?

Yes, we offer samples for customer evaluation. Please contact us to discuss your sample requirements. -

What quality standards do your products meet?

All of our products meet ISO 9001 and other international quality standards. We perform strict quality control tests to ensure compliance. -

Can you handle large-volume orders?

Yes, our production facility is capable of handling both small and large-volume orders, ensuring timely delivery for all customers.

Packaging

-

Wooden Crates: Sturdy wooden crates are used for large and heavy items to ensure safe transportation.

-

Cardboard Boxes: Lighter products are packed in durable cardboard boxes for ease of handling and storage.

-

Foam Padding: All packages are filled with foam padding to protect the parts from damage during transit.

-

Waterproof and Moisture-Proof Packaging: We use special packaging materials to prevent moisture and water damage during shipping.

-

Custom Packaging: We offer custom packaging solutions to meet the specific requirements of our customers.

|

|

|

|

|

|

|

|

|

|

Logistics

-

Sea Freight: Cost-effective for large shipments and global distribution.

-

Air Freight: Fast delivery for urgent orders or smaller shipments.

-

Land Transport: Available for regional customers and short-distance deliveries.

-

Multimodal Transportation: Combining various transport modes for efficient and flexible shipping solutions.

-

Courier Services: For small, time-sensitive orders, we offer reliable express delivery services.

Contact Us – Let's Collaborate!

Ready to take the next step? Shaanxi Peakrise Metal Co., Ltd. is here to provide you with top-tier precision zirconium metal parts tailored to your needs. Contact us today at info@peakrisemetal.com and let's discuss how we can support your next project!