molybdenum wire for edm

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Got it. Here’s a detailed product introduction page for Shaanxi Peakrise Metal Co., Ltd. focusing on "Molybdenum Wire for EDM":

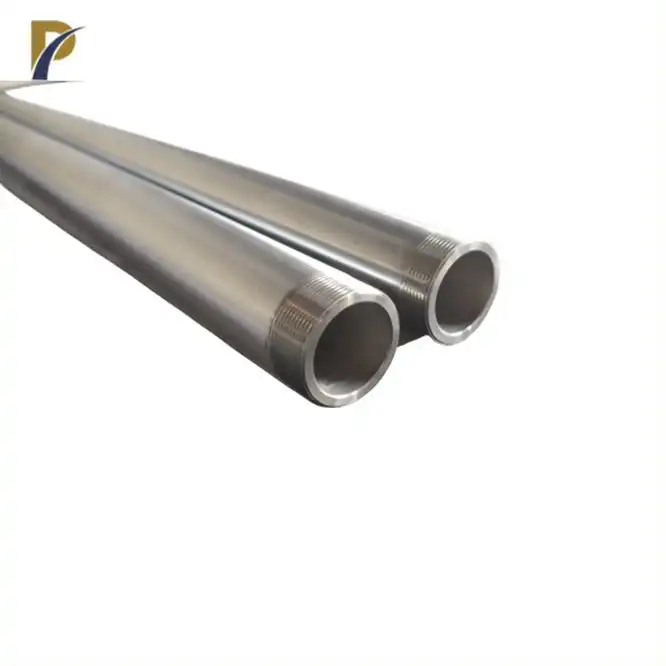

Molybdenum Wire for EDM

Product Introduction

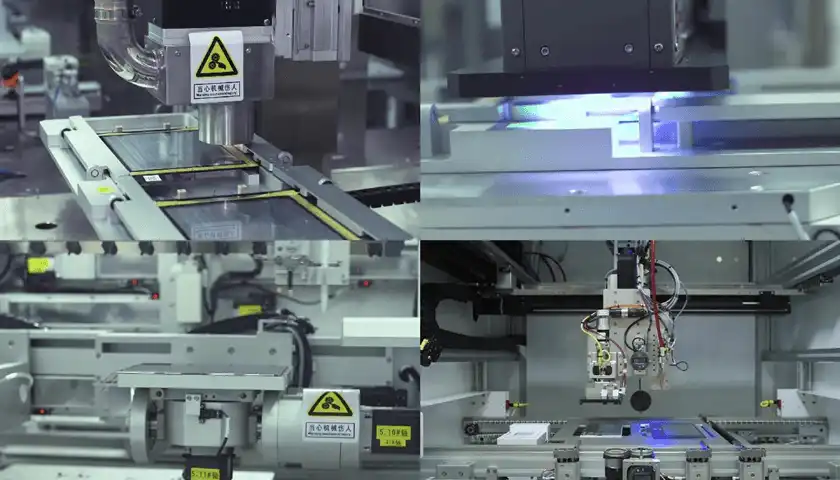

Molybdenum wire is a crucial component in the Electrical Discharge Machining (EDM) process, known for its exceptional performance in precision cutting and high-temperature applications. At Shaanxi Peakrise Metal Co., Ltd., we pride ourselves on being a leading supplier of molybdenum wire, delivering high-quality products tailored to meet the demanding needs of the global market.

Our molybdenum wire is meticulously crafted to provide superior stability, electrical conductivity, and resistance to wear and thermal stress. With extensive experience in the production of non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel, Shaanxi Peakrise Metal Co., Ltd. has established a reputation for excellence and reliability in the industry.

|

|

|

Product Parameters

| Parameter | Value |

|---|---|

| Material | Molybdenum (Mo) |

| Wire Diameter | 0.18 mm |

| Wire Length | 1000 m - 2000 m |

| Tensile Strength | 550 MPa |

| Melting Point | 2623°C |

| Electrical Conductivity | 60% IACS |

| Density | 10.2 g/cm³ |

| Size range | 200mm wire segment weight deviation(%) | Diameter deviation (%) | ||||

|

Diameter (μm) |

Weight (mg) |

0 grade | Ⅰ grade | Ⅱ grade | Ⅰgrade | Ⅱ grade |

| 20≤30 | 0.65≤1.47 | ±2.0 | ±2.5 | ±3.0 | — | — |

| 30≤40 | 1.47≤2.61 | ±1.5 | ±2.0 | ±3.0 | — | — |

| 40 | 2.61 | ±1.0 | ±1.5 | ±3.0 | — | — |

| 400≤d≤600 | — | — | — | — | ±1.5 | ±2.5 |

| 600≤5500 | — | — | — | — | ±1.0 | ±2.0 |

|

Molybdenum Content |

Other Elements Content Total |

Each Other Element Content |

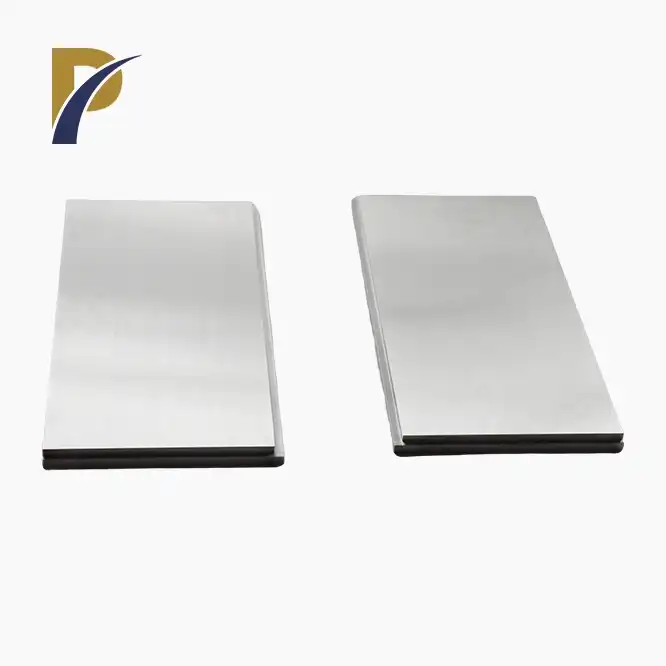

| MO≥99.95% | ≤0.05% | ≤0.01% |

Product Functions

- Precision Cutting: Molybdenum wire is highly effective for precision cutting in EDM processes due to its low thermal expansion and excellent conductivity.

- High-Temperature Stability: It maintains structural integrity and performance at high temperatures, making it ideal for intricate machining tasks.

- Wear Resistance: The wire's durability ensures a longer lifespan and consistent performance, reducing downtime and maintenance costs.

- Electrical Conductivity: Superior conductivity ensures efficient energy transfer during the EDM process, improving the overall efficiency of the operation.

Product Applications

- Precision Engineering: Ideal for machining complex geometries and fine details in metal components.

- Aerospace Industry: Used for cutting high-strength alloys and materials in aerospace components.

- Automotive Manufacturing: Essential for producing intricate parts and high-tolerance components.

- Tooling and Molds: Perfect for creating precise tooling and molds used in various manufacturing processes.

|

|

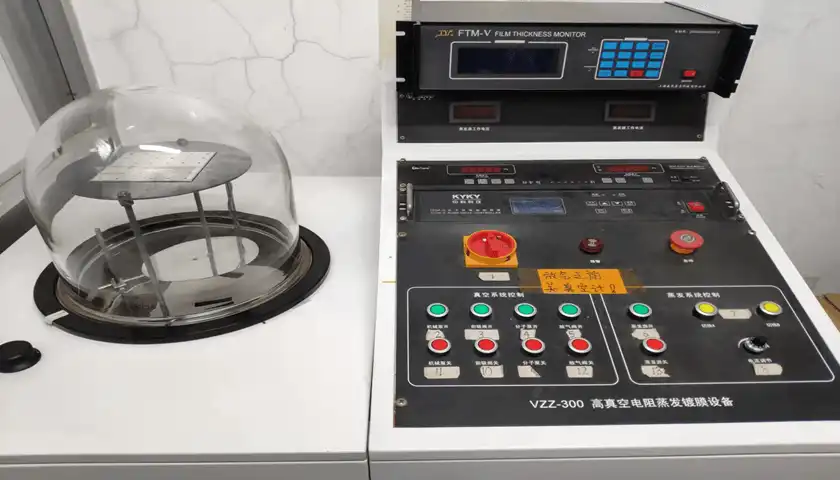

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is a well-established manufacturer specializing in the production of non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Our expertise extends to advanced alloys such as tungsten-copper and molybdenum-copper. With a commitment to quality and innovation, we cater to various industrial applications globally, ensuring our products meet the highest standards.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Packaging: Molybdenum wire is securely spooled and wrapped to prevent contamination and damage.

- Logistics: We offer efficient shipping solutions worldwide, with options for express and standard delivery based on customer needs.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: Extensive experience in the production of high-quality non-ferrous metals.

- Quality Assurance: Rigorous quality control processes ensure the highest standards of performance and reliability.

- Customization: Flexible manufacturing capabilities to meet specific customer requirements.

- Global Reach: Efficient logistics and shipping solutions for timely delivery to international clients.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. supports OEM services, offering customized molybdenum wire solutions tailored to your specific needs. Whether you require unique dimensions, packaging, or special properties, our team is ready to assist you in developing the ideal product.

|

|

Frequently Asked Questions

-

What is the minimum order quantity for molybdenum wire?

- The minimum order quantity varies depending on the wire diameter and length. Please contact us for specific details.

-

Can you provide samples of the molybdenum wire?

- Yes, we offer samples for evaluation purposes. Please reach out to our sales team to request samples.

-

What are the lead times for orders?

- Lead times depend on the order quantity and customization requirements. Typical lead times range from 2 to 6 weeks.

Call to Action (CTA)

Ready to enhance your EDM process with high-quality molybdenum wire? Contact Shaanxi Peakrise Metal Co., Ltd. today to request a quote, discuss your specific requirements, or learn more about our products and services. Reach out to us at info@peakrisemetal.com or call us at [phone number] for prompt assistance.

Feel free to adjust any specific details or add more information as needed!

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MOREmolybdenum riveted boat

VIEW MOREmolybdenum riveted boat -

VIEW MOREmolybdenum vacuum boat

VIEW MOREmolybdenum vacuum boat -

VIEW MOREmolybdenum crucibles

VIEW MOREmolybdenum crucibles -

VIEW MOREmolybdenum in x ray tube

VIEW MOREmolybdenum in x ray tube -

VIEW MOREtungsten welding electrodes

VIEW MOREtungsten welding electrodes -

VIEW MOREtungsten heavy alloy

VIEW MOREtungsten heavy alloy -

VIEW MOREhigh temperature furnace tungsten crucible

VIEW MOREhigh temperature furnace tungsten crucible