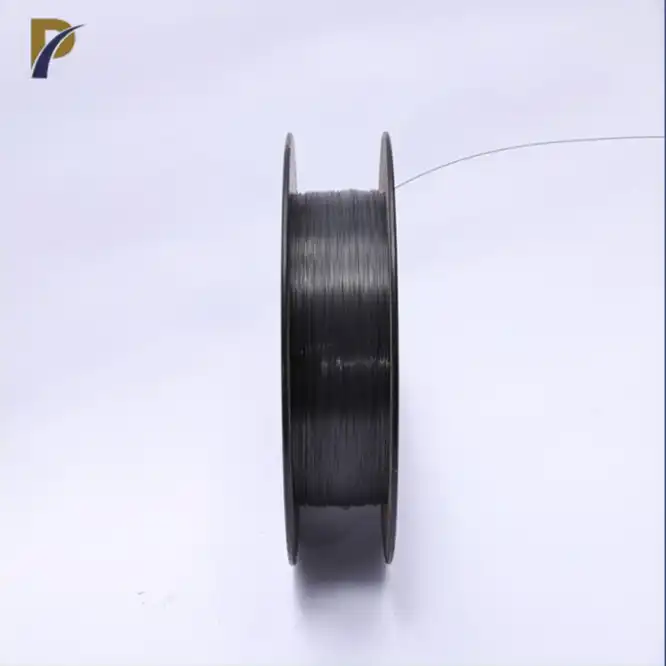

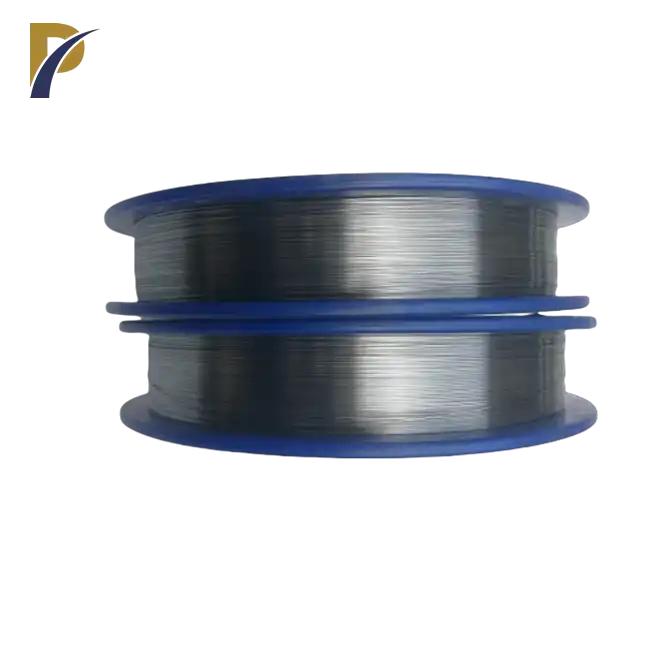

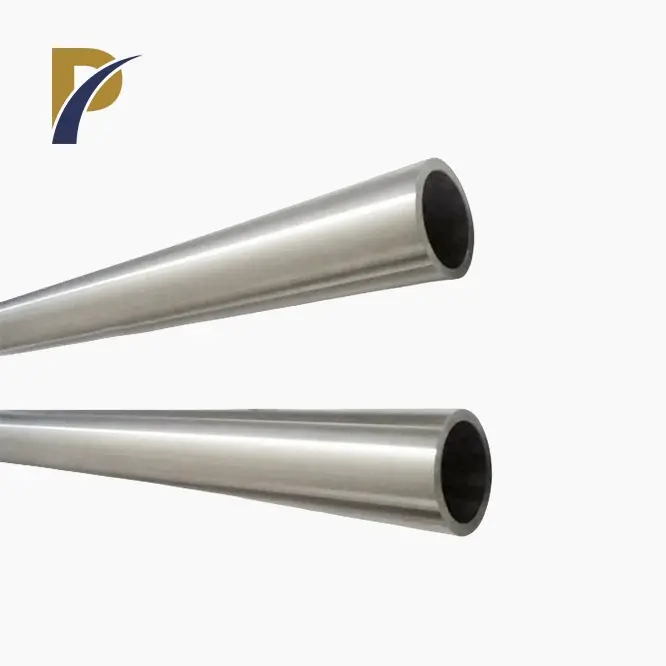

molybdenum wire cut

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Got it! Here’s a draft for the product introduction page:

Molybdenum Wire Cut

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of high-quality molybdenum wire cuts, serving industries worldwide with precision and reliability. Our molybdenum wire cut products are crafted from premium-grade molybdenum, renowned for its exceptional performance in high-temperature and high-stress applications. Molybdenum is a refractory metal known for its superior strength, thermal stability, and resistance to corrosion, making it an ideal choice for demanding environments.

As a trusted manufacturer in the non-ferrous metals sector, Shaanxi Peakrise Metal Co., Ltd. leverages advanced technology and stringent quality control to deliver molybdenum wire cuts that meet the highest industry standards. Our expertise in producing molybdenum wire cuts is backed by years of experience and a commitment to innovation, ensuring that our clients receive products that not only meet but exceed their expectations.

Product Parameters

| Parameter | Value |

|---|---|

| Wire Diameter | 0.1 mm - 3 mm |

| Length | Customizable |

| Purity | ≥99.95% |

| Density | 10.28 g/cm³ |

| Melting Point | 2623°C |

| Electrical Resistivity | 5.2 μΩ·m |

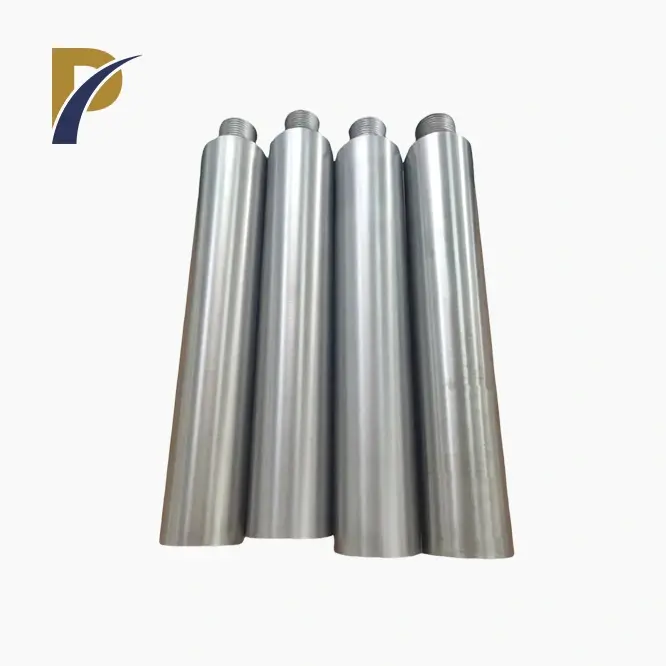

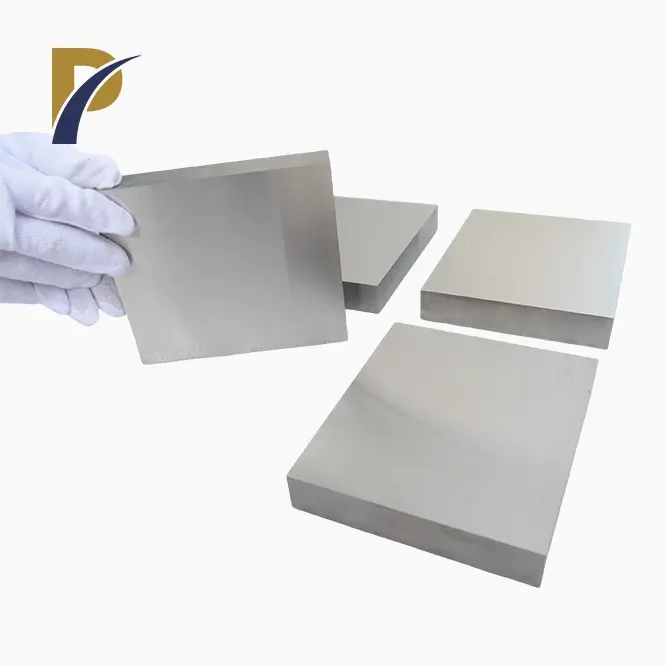

Molybdenum products by Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

Physical and Chemical Properties

Molybdenum wire cuts possess several notable physical and chemical properties:

- High Melting Point: Molybdenum has a melting point of 2623°C, which makes it suitable for high-temperature applications.

- Excellent Strength: Molybdenum maintains its strength at high temperatures, ensuring durability and reliability.

- Corrosion Resistance: The wire cuts exhibit strong resistance to oxidation and corrosion, even in harsh environments.

- Thermal Conductivity: Molybdenum’s high thermal conductivity allows for effective heat dissipation, essential in many industrial processes.

Product Applications

- Electronic Devices: Molybdenum wire cuts are used in electronic components for their excellent electrical and thermal properties.

- Aerospace: In aerospace applications, molybdenum’s high-temperature resistance makes it a crucial material for various components.

- Metal Processing: The wire cuts are employed in metal processing industries for their precision and durability.

- Semiconductor Manufacturing: Molybdenum wire cuts are utilized in the semiconductor industry for their reliability in high-precision environments.

|

|

Manufacturing Process and Production Flow

Our production process involves several key steps to ensure the highest quality molybdenum wire cuts:

- Material Sourcing: We source high-purity molybdenum from reputable suppliers.

- Melting and Alloying: The molybdenum is melted and alloyed to achieve the desired composition.

- Drawing: The alloy is drawn into wire of various diameters and lengths.

- Cutting and Finishing: The wire is cut to specified lengths and undergoes finishing processes to ensure precision and quality.

Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. is equipped with state-of-the-art facilities for the production of non-ferrous metals. Our advanced manufacturing equipment and stringent quality control processes ensure that every product meets our high standards of excellence.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

We package our molybdenum wire cuts using high-quality materials to prevent damage during transportation. Our logistics team ensures timely and secure delivery to our clients worldwide.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Experience: With years of experience in the non-ferrous metals industry, we have the expertise to meet your needs.

- Quality: Our products are manufactured to the highest standards, ensuring reliability and performance.

- Customization: We offer customizable solutions to meet specific requirements.

- Customer Support: Our dedicated support team is available to assist with any queries or concerns.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers OEM services to provide tailored solutions based on your specifications. We are committed to delivering products that meet your exact requirements.

-

What is the maximum length available for molybdenum wire cuts?

- We offer customizable lengths to suit your needs.

-

What is the purity level of your molybdenum wire cuts?

- Our molybdenum wire cuts have a purity of ≥99.95%.

-

Can you provide samples for testing?

- Yes, we can provide samples upon request.

Call to Action

Ready to experience the exceptional quality of our molybdenum wire cuts? Contact us today to discuss your requirements or request a quote. Trust Shaanxi Peakrise Metal Co., Ltd. for your non-ferrous metal needs.

Feel free to adjust any specifics as needed!