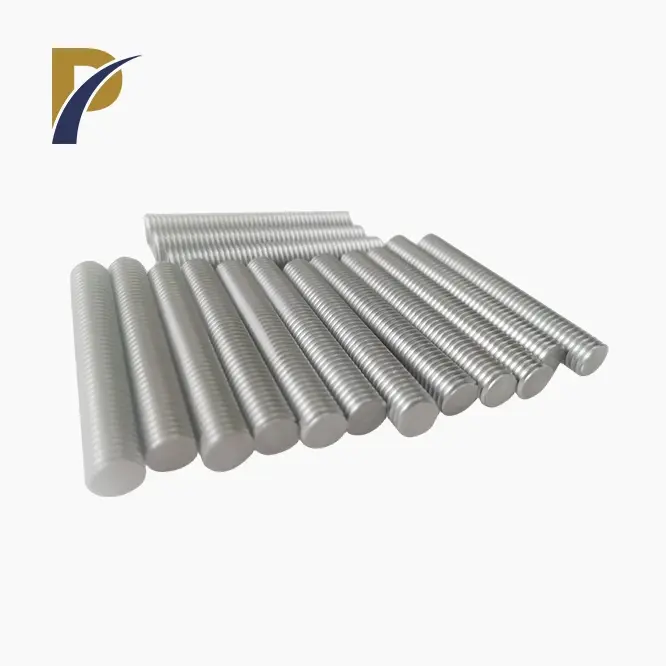

molybdenum edm wire

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Molybdenum EDM Wire - Product Introduction

Molybdenum EDM wire with a diameter of 0.18 is referred to as 0.18 wire cutting molybdenum wire. It is frequently referred to as wire EDM molybdenum wire since wire EDM machine tools frequently employ it. An EDM wire cutting machine must be used for cutting wire. The basic physical principle is that free positive ions and electrons accumulate in the field, and soon form an ionized conductive channel. A current is formed between the two plates, resulting in countless collisions between particles, forming a The plasma area, which quickly rose to high temperatures of 800 to 1200 degrees, instantly melted some material on the surfaces of the two conductors. Therefore, the wire cutting machine has strict requirements on molybdenum wire, such as Mo content of not less than 99.3%, good tensile strength, low elongation, large crimp rate, uniform wire diameter, and no oxide layer on the surface.

Product Specifications

| Parameter | Value |

|---|---|

| Diameter | 0.18 mm |

| Tensile Strength | 550 MPa - 700 MPa |

| Electrical Conductivity | 40 - 55 % IACS |

| Melting Point | 2623°C (4753°F) |

| Density | 10.28 g/cm³ |

| Hardness | 220 HV |

|

|

|

Physical and Chemical Properties

- High Melting Point: Molybdenum EDM wire has a melting point of 2623°C, making it suitable for high-temperature operations.

- Density: With a density of 10.28 g/cm³, molybdenum wire offers robust mechanical properties.

- Electrical Conductivity: Ranges from 40 to 55 % IACS, ensuring efficient electrical discharge.

- Tensile Strength: Varies between 550 MPa to 700 MPa, providing durability under operational stress.

Product Applications

- Aerospace: Ideal for machining complex aerospace components requiring high precision and durability.

- Automotive: Used in the manufacturing of intricate automotive parts and tools.

- Electronics: Essential for producing fine electronic components with high accuracy.

- Medical Devices: Suitable for crafting precise parts in medical equipment and devices.

Trends: The demand for molybdenum EDM wire is growing with advancements in technology, particularly in sectors requiring ultra-precise components. Innovations in wire technology are enhancing performance, expanding applications, and improving cost-effectiveness.

|

|

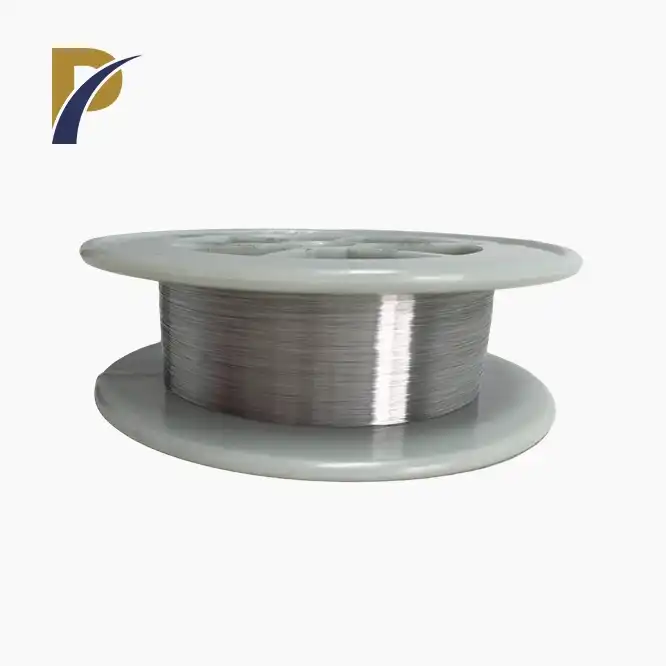

Production Process and Workflow

- Material Sourcing: We source high-purity molybdenum for optimal performance.

- Wire Drawing: The molybdenum is drawn into wire form using advanced machinery.

- Quality Control: Rigorous testing for consistency in diameter, tensile strength, and conductivity.

- Packaging: The wire is carefully packaged to prevent damage during transit.

|

|

|

|

About Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer specializing in non-ferrous and refractory metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Our state-of-the-art facilities and skilled workforce ensure the highest standards of product quality and performance.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Packaging: The EDM wire is packaged in protective materials to prevent damage.

- Shipping: We offer global shipping with reliable delivery times to meet your needs.

|

|

|

|

|

|

|

|

Why Choose Us?

- Experience: Extensive expertise in producing high-quality refractory metals.

- Quality Assurance: Rigorous testing and quality control procedures.

- Customization: Tailored solutions to meet specific client requirements.

- Global Reach: Reliable shipping and support to international markets.

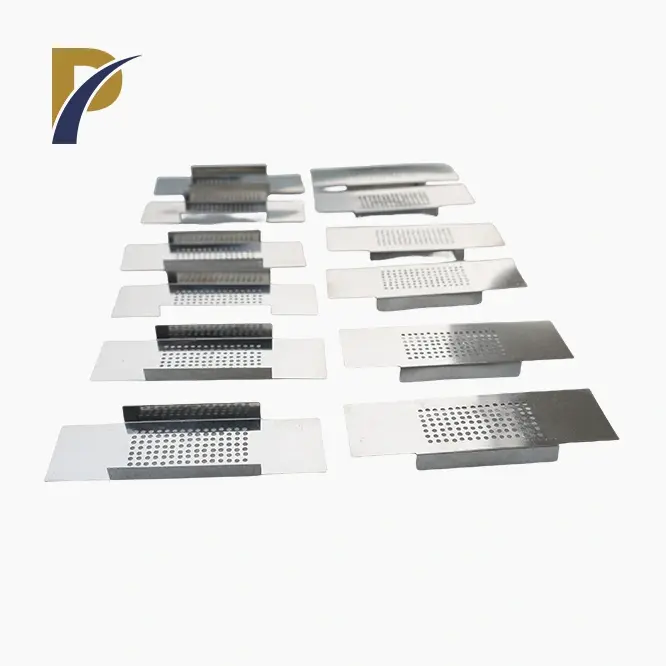

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers OEM/ODM services for customized molybdenum EDM wire. We can produce wire to meet your unique specifications and requirements, ensuring that you receive a product that fits perfectly with your operations.

|

|

|

|

|

|

|

|

|

FAQs

- What is the standard diameter of molybdenum EDM wire?

- Diameters range from 0.10 mm to 1.00 mm.

- How is the wire packaged?

- The wire is securely packaged to prevent damage during transit.

- Can you provide custom diameters?

- Yes, we offer custom sizes to meet specific needs.

Call to Action (CTA)

Ready to experience the superior performance of our molybdenum EDM wire? Contact us today for more information or to request a quote. Trust Shaanxi Peakrise Metal Co., Ltd. for your precision machining needs!

_1736239217106.webp)

_1736239217130.webp)

_1736239217104.webp)

_1736239217241.webp)