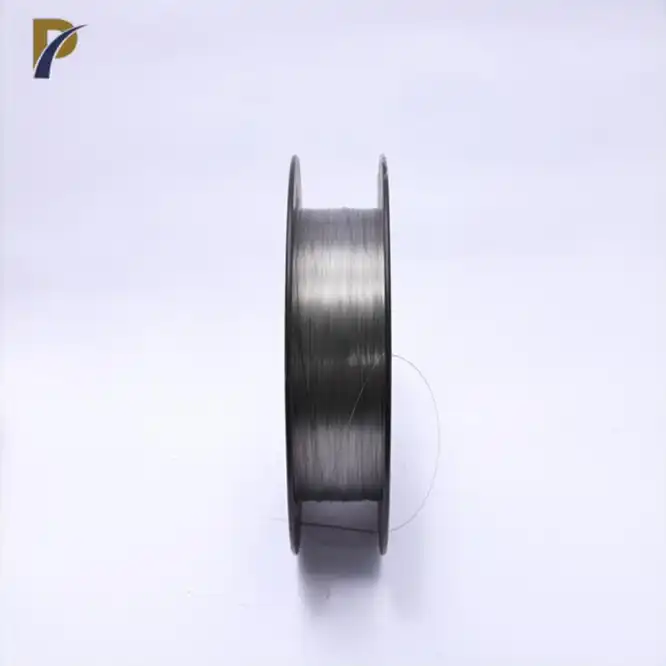

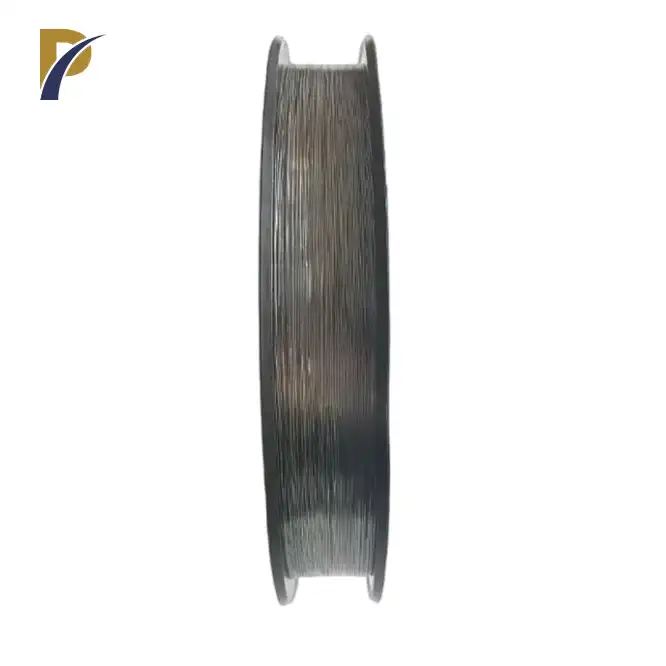

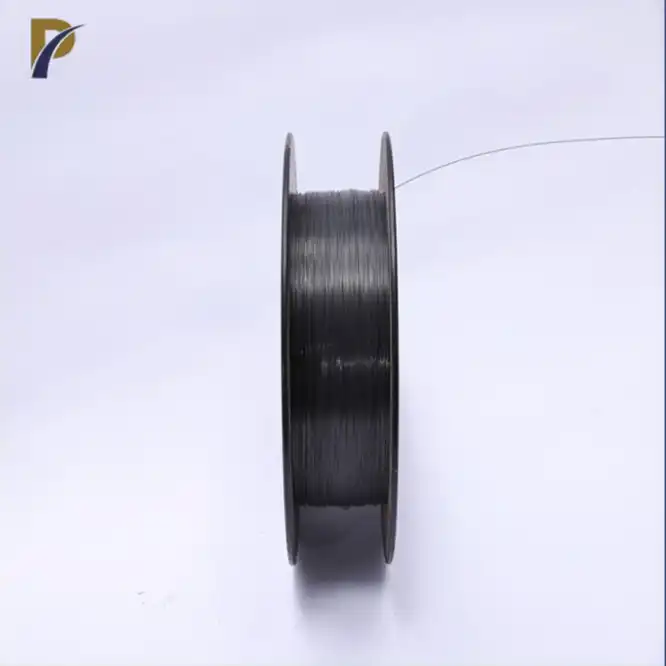

guangming molybdenum wire

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Product Introduction: Guangming Molybdenum Wire

Guangming Molybdenum Wire is an essential material used in a variety of high-temperature applications due to its outstanding strength, conductivity, and resistance to corrosion and heat. As a key component in industries such as electronics, lighting, and semiconductor manufacturing, molybdenum wire ensures high performance even under the most demanding conditions. Shaanxi Peakrise Metal Co., Ltd. is a trusted supplier of Guangming Molybdenum Wire, offering superior quality, precision, and customization services to meet the specific needs of our global clientele. With over a decade of experience in the production and supply of molybdenum wire, we are committed to delivering products that exceed industry standards, ensuring long-term reliability and efficiency for your projects. Whether you are in need of molybdenum wire for wire cutting, welding, or filament production, Shaanxi Peakrise Metal Co., Ltd. has the expertise and production capacity to support your business.

Product Parameters Table

| Parameter | Value | Unit |

|---|---|---|

| Purity | ≥ 99.95% | - |

| Diameter Range | 0.02 mm – 3.0 mm | mm |

| Tensile Strength | 700 – 900 MPa | MPa |

| Density | 10.2 g/cm³ | g/cm³ |

| Melting Point | 2623 °C | °C |

| Surface Finish | Bright/Black | - |

| Length | Customizable (as per request) | m |

|

|

|

Physical and Mechanical Properties

- High melting point: Molybdenum wire can withstand extreme temperatures, making it suitable for high-temperature applications.

- Low thermal expansion: The wire exhibits minimal expansion when exposed to heat, ensuring dimensional stability.

- Excellent electrical conductivity: Molybdenum wire efficiently conducts electricity, making it an excellent choice for electrical and electronic applications.

- Corrosion resistance: The material’s resistance to oxidation and chemical reactions allows it to perform well in harsh environments.

- High tensile strength: The wire is robust, ensuring durability and long life even under mechanical stress.

| Use temperature | 1800°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Highest temperature | 2200°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quantitative analysis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | O | Ca | Fe | Pb | Al | Cd | Si | Bi | Mg | P | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | Ni | N | Sb | Sn | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Applications

- Semiconductor Manufacturing: Molybdenum wire is critical in semiconductor production, where precision and high purity are required.

- Lighting Industry: It is widely used in incandescent and halogen bulbs, where it serves as support and lead wires, ensuring optimal performance and longevity.

- Electrical Discharge Machining (EDM): Molybdenum wire is highly valued for wire cutting in EDM, providing precision and minimal wear.

- Aerospace Industry: Due to its high-temperature resistance and low thermal expansion, molybdenum wire is used in aerospace components to handle extreme conditions.

- Chemical Processing: Its corrosion resistance makes it suitable for use in harsh chemical environments, especially in reactors and pipelines.

|

|

|

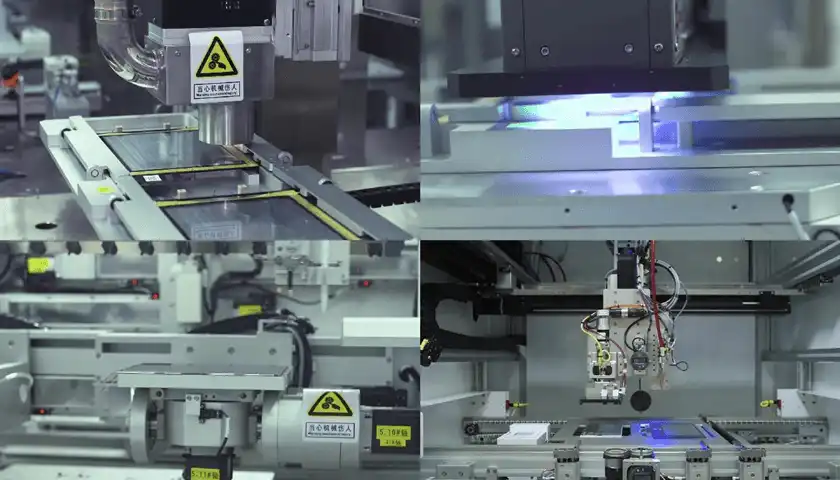

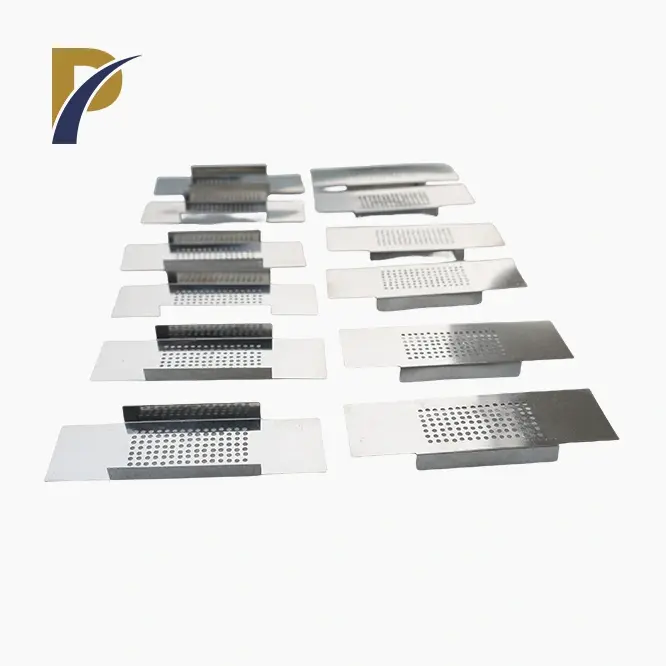

Product Process and Production Flow

- Raw Material Selection: Only high-purity molybdenum raw materials are used to ensure the quality of the wire.

- Vacuum Sintering: Molybdenum is sintered under vacuum to achieve the required density and grain structure.

- Hot and Cold Rolling: The sintered material is rolled into wire form through a combination of hot and cold processes.

- Wire Drawing: The wire is drawn to the desired diameter through precision drawing machines, ensuring uniformity.

- Surface Treatment: The wire is treated for a smooth, bright, or black surface finish, depending on customer specifications.

- Quality Testing: The final product undergoes rigorous testing for diameter, tensile strength, and purity before delivery.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is equipped with state-of-the-art production facilities, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, and various wire drawing machines. With a highly skilled workforce and an emphasis on R&D, we consistently deliver high-quality molybdenum wire to meet the needs of diverse industries globally. Our factory also adheres to strict quality control standards, ensuring that each batch meets the specifications required by our customers.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Box Packaging: Suitable for heavy or large shipments, offering strong protection.

- Carton Packaging: Ideal for smaller quantities, ensuring cost-effective and secure delivery.

- Foam-Filled Packaging: Provides additional cushioning, preventing damage during transport.

- Waterproof and Moisture-Proof Packaging: Ensures the wire remains in perfect condition during long-term storage or overseas transport.

- Custom Packaging: Tailored to meet specific customer requirements and international shipping standards.

|

|

|

|

|

|

|

|

|

|

Logistics options include:

- Sea Freight: Economical for large shipments over long distances.

- Air Freight: Fast and secure, suitable for urgent deliveries.

- Land Transport: Efficient for regional deliveries.

- Multimodal Transport: A combination of air, sea, and land transport for global reach.

- Courier Services: Ideal for small, urgent orders requiring rapid delivery.

Why Choose Us?

- Expertise and Experience: With over a decade of experience in molybdenum wire production, we have refined our processes to ensure precision and quality.

- Comprehensive Product Range: We offer a wide range of molybdenum and other non-ferrous metal products, ensuring we can meet any customer requirement.

- Advanced Production Facilities: Our state-of-the-art equipment allows us to produce high-quality wire with consistency and efficiency.

- Global Exporter: Our products are exported worldwide, with a strong reputation for reliability in markets such as the USA, Germany, and South Korea.

- Customization Capabilities: We offer full OEM and ODM services, allowing you to customize the molybdenum wire to your exact specifications.

- Commitment to Quality: We follow strict quality control measures at every stage of production to ensure the highest standards.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM and ODM services. We work closely with our clients to deliver customized molybdenum wire that meets their specific requirements, including size, coating, and packaging options. Our flexible production capabilities ensure that we can accommodate both small and large orders with fast turnaround times.

|

|

|

|

|

|

|

|

|

Frequently Asked Questions (FAQ)

-

What is the purity of Guangming Molybdenum Wire?

Our molybdenum wire has a purity of 99.95%, ensuring high performance in demanding applications. -

Can I customize the diameter of the molybdenum wire?

Yes, we offer customizable diameters ranging from 0.02 mm to 3.0 mm. -

What surface finishes are available?

We offer bright and black surface finishes, depending on your requirements. -

What are the delivery lead times?

Delivery times vary based on order size, but we generally fulfill orders within 2-4 weeks. -

Do you offer international shipping?

Yes, we ship globally using sea, air, and land transport options to ensure timely delivery.

Contact Us (CTA)

For more information or to place an order, contact Shaanxi Peakrise Metal Co., Ltd. today. Our team is ready to assist you with any questions and provide customized solutions to meet your molybdenum wire needs. We look forward to establishing a long-term partnership with you. Email us at info@peakrisemetal.com for inquiries and quotes.