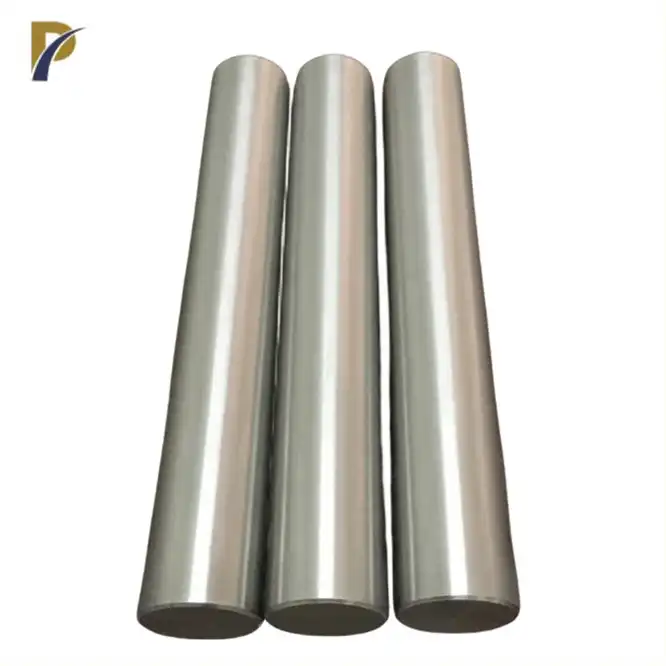

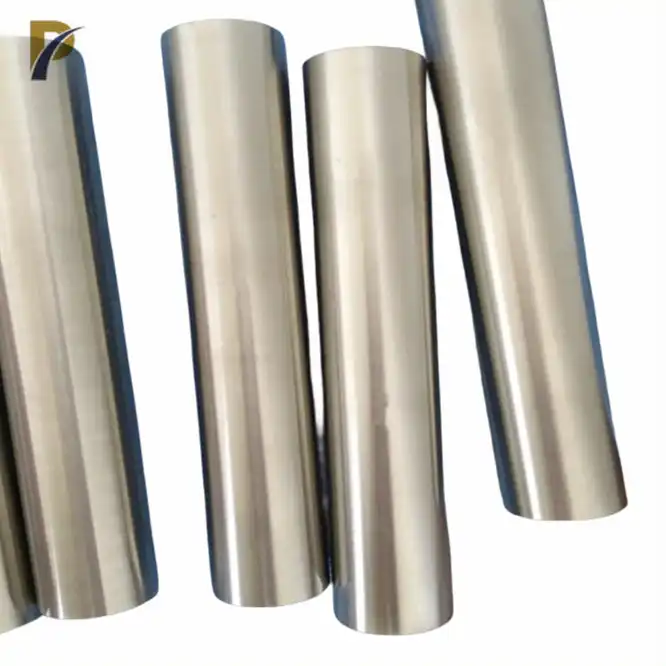

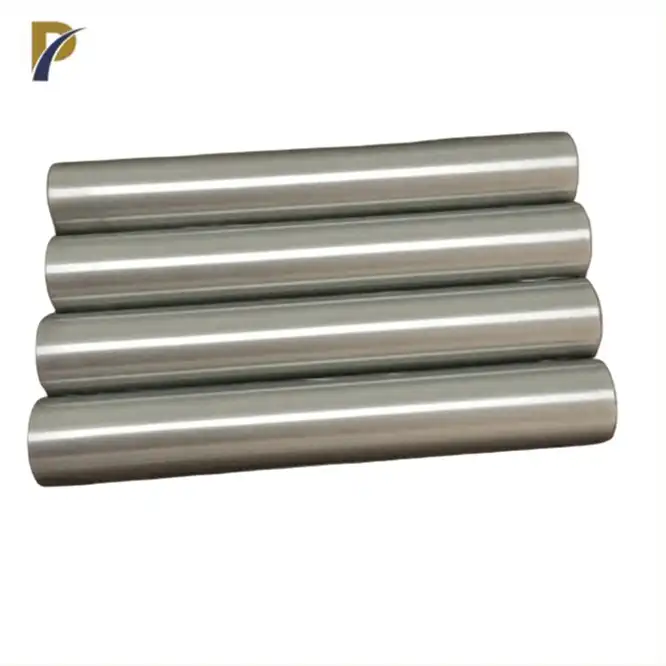

tungsten molybdenum alloys rod

W Content: 50% (wt%)

Mo Content: 50% (wt%)

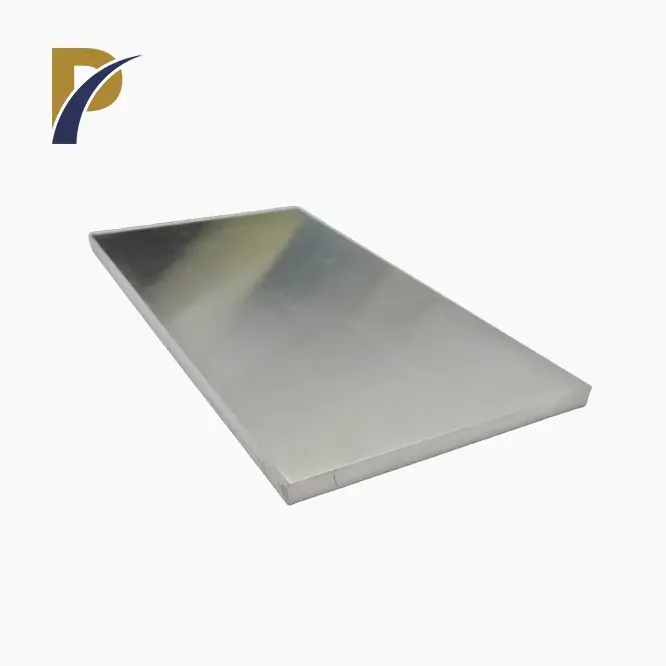

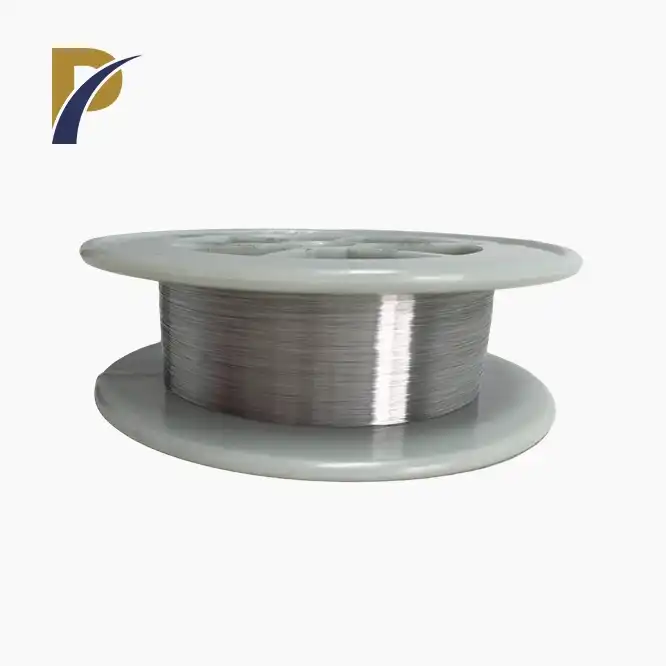

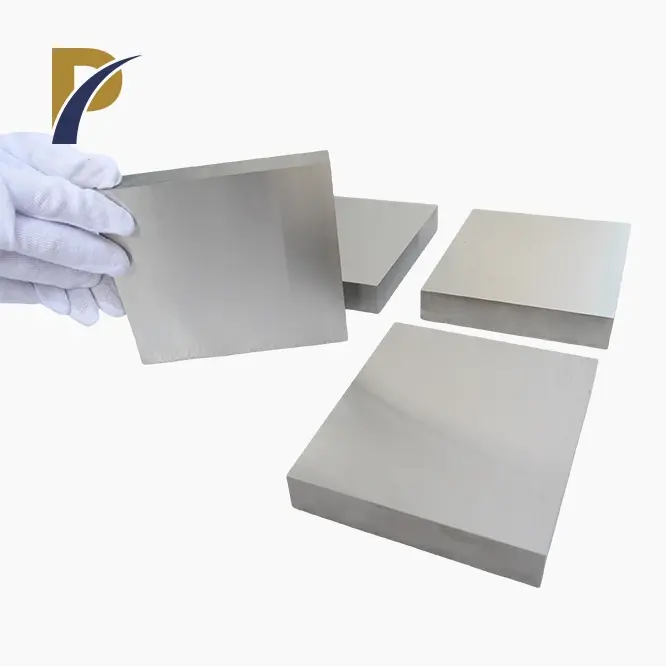

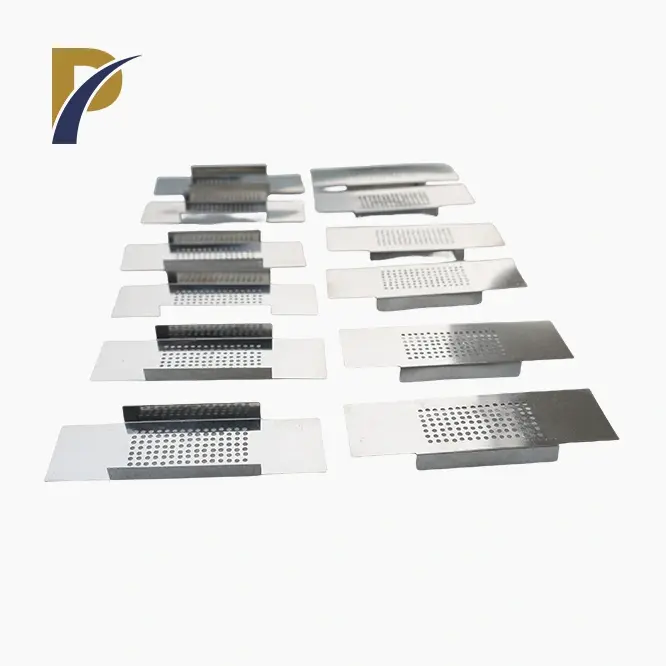

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction

Tungsten molybdenum alloys are critical materials in industries where strength, heat resistance, and durability are essential. Known for their exceptional performance in high-temperature environments, these alloys combine the best properties of tungsten and molybdenum, making them ideal for aerospace, electronics, and industrial applications. Tungsten molybdenum alloys boast excellent thermal conductivity, corrosion resistance, and low thermal expansion, contributing to their wide use in manufacturing components that must withstand extreme conditions.

Shaanxi Peakrise Metal Co., Ltd. stands as a leading supplier of tungsten molybdenum alloys, delivering high-quality products to global markets. With over a decade of experience in non-ferrous metals production, including tungsten, molybdenum, tantalum, and niobium alloys, our company has built a solid reputation. We prioritize product quality and customer satisfaction, leveraging our advanced manufacturing processes to meet the strict demands of industries worldwide. Our tungsten molybdenum alloys are trusted by customers in countries like the United States, South Korea, Germany, and Australia, among others.

Product Parameters

| Property | Value |

|---|---|

| Density | 16.4 g/cm³ |

| Melting Point | 2,620°C |

| Thermal Conductivity | 140 W/mK |

| Coefficient of Expansion | 4.8 x 10⁻⁶ /°C |

| Hardness (Vickers) | 343 HV |

| Electrical Resistivity | 5.5 µΩ·cm |

| Composition | Percentage (%) |

|---|---|

| Tungsten (W) | 80 |

| Molybdenum (Mo) | 20 |

| Impurities | < 0.1 |

| Oxygen Content | 0.05 |

| Carbon Content | 0.01 |

| Mechanical Property | Value |

|---|---|

| Tensile Strength | 700 MPa |

| Elongation | 10% |

| Modulus of Elasticity | 385 GPa |

| Yield Strength | 500 MPa |

| Impact Resistance | 30 J |

|

|

|

Physical and Mechanical Properties

Tungsten molybdenum alloys are valued for their outstanding physical and mechanical properties. These materials feature:

- High Temperature Resistance: Capable of enduring temperatures beyond 2,600°C, making them suitable for furnace and aerospace components.

- Excellent Thermal Conductivity: The ability to transfer heat efficiently is crucial in electronics and thermal management systems.

- Low Coefficient of Thermal Expansion: Ideal for applications requiring stability under temperature fluctuations, such as in semiconductor manufacturing.

- Durability and Strength: The alloys maintain high strength under stress, which is essential in high-load industrial operations.

- Corrosion Resistance: Resistant to oxidation and corrosion, even in harsh chemical environments.

Product Functions

- Heat Shields: Tungsten molybdenum alloys are widely used in furnace linings and shields due to their high melting points.

- Aerospace Components: In aerospace, these alloys help build components exposed to high heat, such as turbine blades and rocket nozzles.

- Electronic Devices: The alloys’ excellent electrical properties make them essential in semiconductors, integrated circuits, and thermal management systems.

- Industrial Machinery: Due to their strength and wear resistance, these alloys are ideal for heavy-duty equipment components.

Product Applications

Tungsten molybdenum alloys’ exceptional properties translate into multiple applications across diverse industries:

- Aerospace: Used in the construction of heat-resistant parts, especially in engines and propulsion systems.

- Electronics: Ideal for heat sinks, semiconductor devices, and electrical contacts due to their high thermal conductivity.

- Medical Devices: Found in radiation shielding for diagnostic equipment and in surgical tools due to their durability and precision.

- Industrial Manufacturing: Utilized in hot isostatic pressing (HIP) furnaces and other high-temperature industrial applications.

- Defense: These alloys are often used in military applications for ballistic protection and missile components due to their hardness and strength.

|

|

Product Process and Production Flow

Our manufacturing process ensures that we deliver the highest quality tungsten molybdenum alloys, beginning with the selection of raw materials and followed by rigorous refining and alloying procedures. Key stages include:

- Raw Material Selection: High-purity tungsten and molybdenum ores are sourced and processed.

- Alloying: The materials are melted in a vacuum arc melting furnace, ensuring a uniform distribution of elements.

- Rolling and Forging: After cooling, the alloys are rolled and forged into desired shapes and sizes.

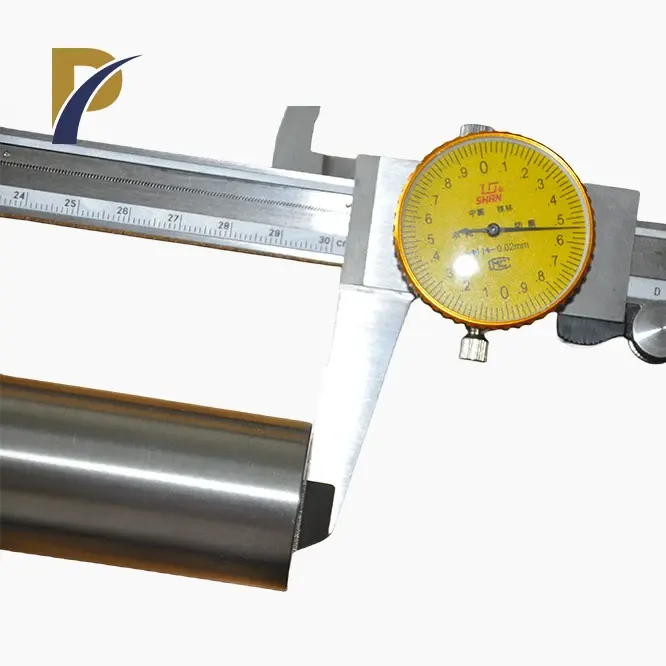

- Quality Testing: Each batch undergoes stringent testing for mechanical properties, composition accuracy, and defect detection.

- Finishing: Products are polished and prepared for packaging and shipment.

Precision-Engineered Molybdenum-Tungsten Alloy Tailored to Your Needs!

At Peakrise Metal, your requirements take top priority. With over a decade of expertise, we transform complex ideas into practical solutions through our precision-engineered molybdenum tungsten alloy. From initial design to detailed specification adjustments, every step of our manufacturing process is customized to meet your exact demands.

Customization Options for Molybdenum Tungsten Alloy:

Size and Shape: Adjust the length, width, and overall design to match specific applications, ensuring seamless compatibility with various equipment and working conditions.

Purity: Choose from different molybdenum tungsten purity levels to achieve optimal performance in specialized applications.

Coating Treatment: Improve durability with tailored coatings, such as anti-oxidation or conductive layers, suited to specific environments.

Connection Design: Select customized connection methods, including welded joints or bolted structures, for secure and efficient installation.

Packaging: Opt for tailored packaging solutions that ensure safe transport and storage while maintaining product integrity.

Why choose molybdenum-tungsten alloy from Peakrise Metal?

At Peakrise Metal, we uphold industry-leading standards by integrating advanced techniques, innovative technology, and extensive expertise. Our dedication ensures that your specific needs are met with premium molybdenum tungsten alloy solutions.

Expertise and Experience: With over a decade in the industry, we combine cutting-edge technology with deep expertise to deliver top-tier molybdenum tungsten alloy tailored to your exact specifications.

Custom Solutions: We provide fully customized solutions, including unique sizes, shapes, and coatings, to meet precise performance requirements.

Unmatched Quality: Committed to superior manufacturing, we guarantee each molybdenum tungsten alloy product delivers exceptional performance, longevity, and reliability—ensuring excellent value for your investment.

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Why Choose Us?

- Experience: With over a decade of specialization in non-ferrous metal production, we deliver quality that meets global standards.

- Comprehensive Services: From raw material sourcing to final product delivery, we offer full-cycle manufacturing and processing services.

- Advanced Technology: Our facility is equipped with cutting-edge machinery, ensuring consistent quality.

- Global Reach: We export products to over 20 countries, with established partnerships worldwide.

- Customization: We provide OEM and ODM services tailored to specific customer requirements.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers extensive customization options for tungsten molybdenum alloys, catering to the unique needs of our clients. Whether you require specific dimensions, shapes, or compositions, our team works closely with you to deliver tailored solutions that meet your exact specifications.

|

|

|

|

|

|

|

|

|

FAQ

- What are the primary applications of tungsten molybdenum alloys?

- These alloys are used in aerospace, electronics, medical devices, and industrial machinery due to their heat resistance and durability.

- Can you customize the composition of the alloy?

- Yes, we provide customized solutions, including specific tungsten-molybdenum ratios, to suit different applications.

- What are the lead times for orders?

- Depending on the order size and customization, our lead times range from 2 to 6 weeks.

- How do you ensure the quality of your products?

- We perform rigorous testing, including chemical composition analysis and mechanical property testing, to ensure all products meet international standards.

- What are your packaging options?

- We offer wooden, cardboard, and foam-filled packaging, as well as waterproof and custom packaging to ensure safe delivery.

Contact Us

Are you looking for high-quality tungsten molybdenum alloys? Contact Shaanxi Peakrise Metal Co., Ltd. today to discuss your specific needs and get a custom solution tailored to your business. Reach out to us at info@peakrisemetal.com for more information and to place your order!