tungsten and molybdenum alloys

W Content: 50% (wt%)

Mo Content: 50% (wt%)

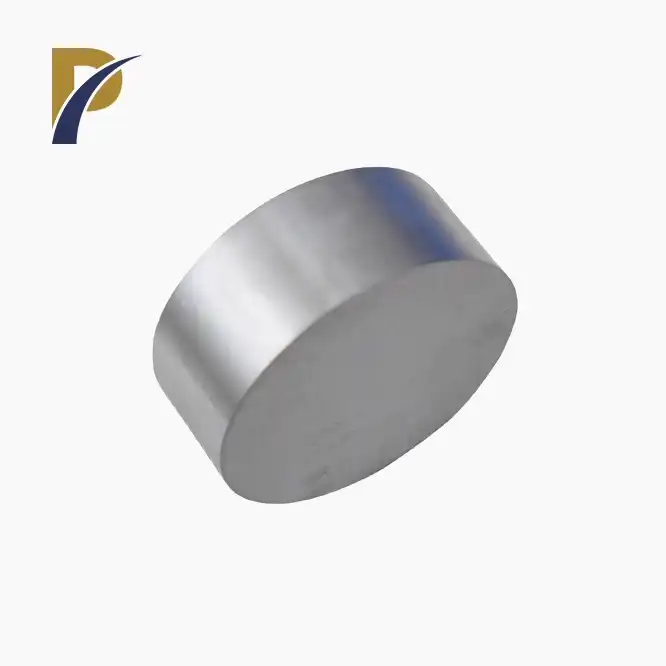

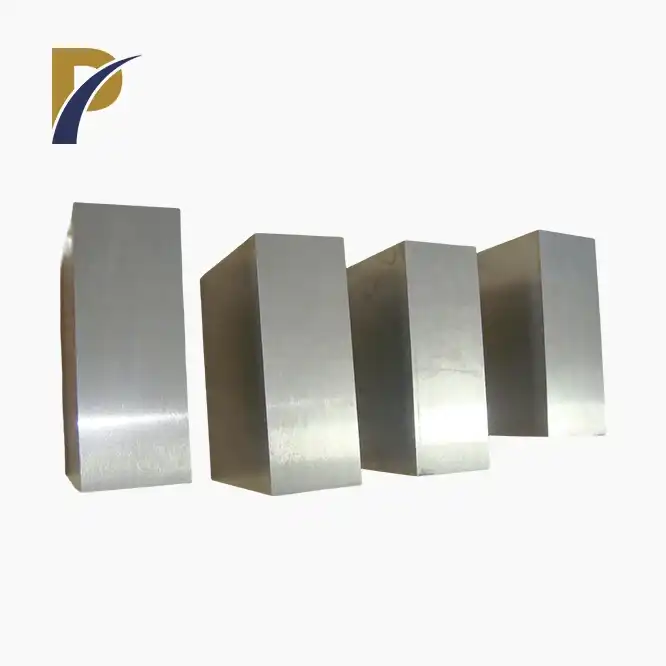

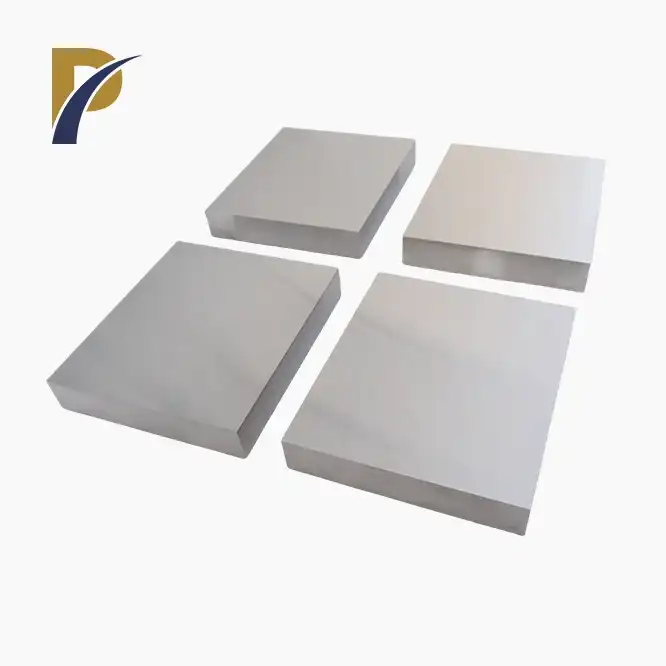

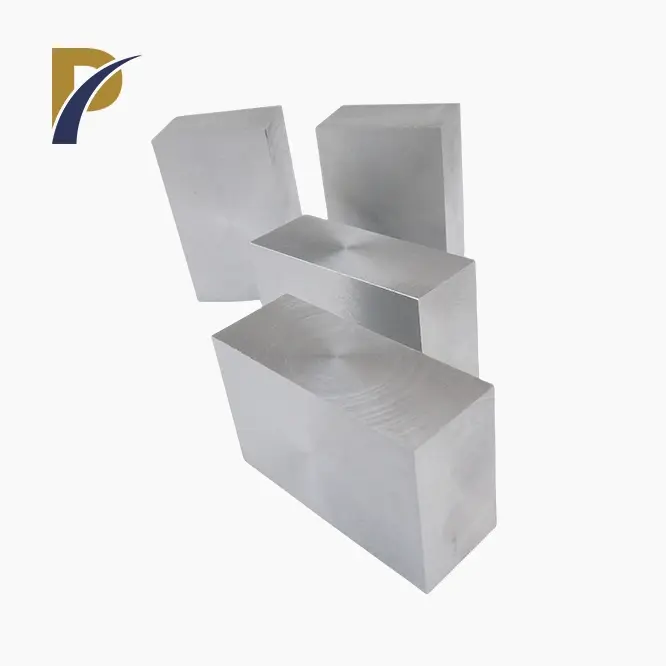

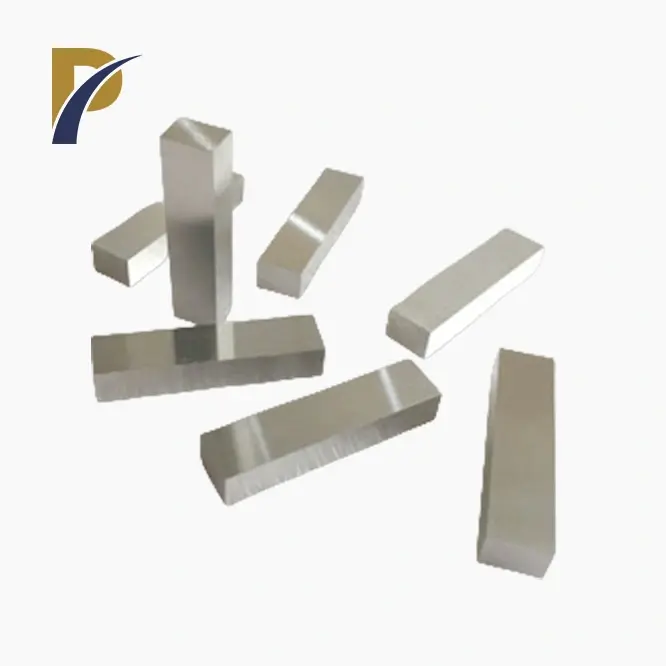

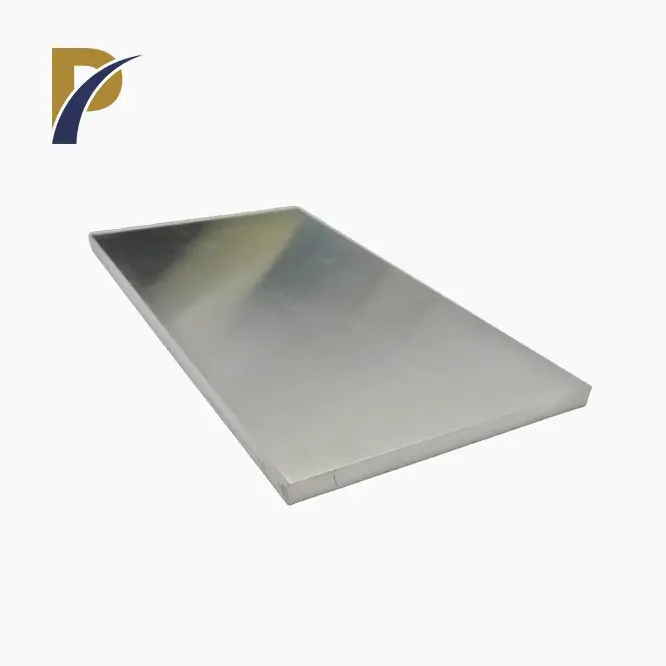

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction: Tungsten and Molybdenum Alloys Block by Shaanxi Peakrise Metal Co., Ltd.

Tungsten and molybdenum alloys are essential materials used in various industries, known for their exceptional physical and chemical properties, including high melting points, corrosion resistance, and excellent thermal conductivity. These alloys are widely applied in the aerospace, electronics, automotive, and defense industries due to their ability to perform under extreme conditions. Tungsten alloys, for example, are valued for their high density and strength, while molybdenum alloys offer superior creep resistance and lower expansion coefficients.

Shaanxi Peakrise Metal Co., Ltd. is a trusted global supplier of high-quality tungsten and molybdenum alloys. With years of experience in non-ferrous metal production, we provide a comprehensive range of products, including tungsten-copper alloys, molybdenum-copper alloys, and high-specific gravity tungsten alloys. Since 2010, we have focused on exporting these materials to international markets, gaining a solid reputation for quality and reliability. Our commitment to innovation, research, and customer satisfaction has allowed us to expand our product offerings and cater to customers worldwide, including in the United States, South Korea, Germany, and Australia.

Product Parameters

| Property | Tungsten Alloy | Molybdenum Alloy | Tungsten-Copper Alloy |

|---|---|---|---|

| Density (g/cm³) | 18.5 – 19.3 | 10.2 | 17.0 – 18.0 |

| Melting Point (°C) | 3422 | 2620 | 3200 |

| Thermal Conductivity (W/mK) | 173 | 138 | 200 |

| Coefficient of Expansion (μm/m°C) | 4.5 | 4.8 | 6.5 |

| Tensile Strength (MPa) | 700 – 1000 | 550 – 700 | 700 – 850 |

| Property | High-Density Tungsten Alloy | Molybdenum-Copper Alloy | Tungsten-Molybdenum Alloy |

|---|---|---|---|

| Density (g/cm³) | 17.0 – 18.0 | 9.0 – 10.0 | 17.5 – 18.5 |

| Melting Point (°C) | 3000 – 3200 | 2600 | 3400 |

| Hardness (HB) | 200 – 350 | 150 – 250 | 320 – 380 |

| Thermal Conductivity (W/mK) | 150 – 180 | 180 – 220 | 140 – 170 |

|

|

|

Physical and Chemical Properties

Tungsten and molybdenum alloys exhibit exceptional mechanical properties, making them ideal for demanding applications:

- High Melting Points: Tungsten has one of the highest melting points of any metal (3422°C), while molybdenum has a melting point of 2620°C, making them suitable for high-temperature environments.

- Corrosion Resistance: Both tungsten and molybdenum alloys are highly resistant to chemical corrosion, particularly in acidic and alkaline environments.

- Thermal Conductivity: Tungsten alloys offer excellent heat conductivity, ensuring stability in thermal applications.

- Strength and Hardness: Tungsten alloys boast high tensile strength and hardness, crucial for heavy-duty industrial applications.

Product Functions

- High-Temperature Stability: Both tungsten and molybdenum alloys can withstand extreme temperatures without degrading, making them ideal for aerospace, electronics, and other high-heat environments.

- Corrosion Resistance: These alloys resist corrosion in harsh environments, enhancing their lifespan in industrial applications.

- Thermal Conductivity: With excellent heat conductivity, tungsten and molybdenum alloys are frequently used in electronics and power transmission equipment to manage heat efficiently.

- High Density and Strength: Tungsten’s high density makes it perfect for counterweights, radiation shielding, and defense applications.

- Creep Resistance: Molybdenum alloys offer outstanding creep resistance, which is essential in long-term, high-stress environments.

|

|

|

|

Product Applications

- Aerospace Industry: Due to their high melting points and resistance to extreme temperatures, tungsten and molybdenum alloys are used in turbine blades, rocket nozzles, and structural components in aerospace engineering.

- Electronics: Tungsten and molybdenum’s thermal conductivity and electrical resistivity make them indispensable in electronics, particularly in semiconductors and electrical contacts.

- Defense Applications: Tungsten alloys are extensively used in military applications such as armor-piercing projectiles, radiation shielding, and other critical defense equipment.

- Automotive Industry: Molybdenum alloys are employed in automotive parts like piston rings and exhaust manifolds due to their strength and corrosion resistance.

- Medical Equipment: Tungsten’s radiation-shielding properties make it valuable in medical imaging devices and radiation therapy machines.

Product Process and Production Flow

- Raw Material Selection: We use high-quality tungsten and molybdenum ores, ensuring purity and material integrity.

- Melting and Sintering: Tungsten and molybdenum are melted in advanced vacuum arc melting furnaces or sintered in intermediate frequency sintering furnaces to produce high-quality alloy ingots.

- Forming and Rolling: The alloys are then processed into sheets, rods, or wire forms through rolling, drawing, and extrusion processes using our advanced equipment.

- Machining and Finishing: The materials are then precisely machined and finished to meet exact customer specifications using plasma cutting, milling, and grinding technologies.

Precision-Engineered Molybdenum-Tungsten Alloy Tailored to Your Needs!

At Peakrise Metal, your requirements take top priority. With over a decade of expertise, we transform complex ideas into practical solutions through our precision-engineered molybdenum tungsten alloy. From initial design to detailed specification adjustments, every step of our manufacturing process is customized to meet your exact demands.

Customization Options for Molybdenum Tungsten Alloy:

Size and Shape: Adjust the length, width, and overall design to match specific applications, ensuring seamless compatibility with various equipment and working conditions.

Purity: Choose from different molybdenum tungsten purity levels to achieve optimal performance in specialized applications.

Coating Treatment: Improve durability with tailored coatings, such as anti-oxidation or conductive layers, suited to specific environments.

Connection Design: Select customized connection methods, including welded joints or bolted structures, for secure and efficient installation.

Packaging: Opt for tailored packaging solutions that ensure safe transport and storage while maintaining product integrity.

Why choose molybdenum-tungsten alloy from Peakrise Metal?

At Peakrise Metal, we uphold industry-leading standards by integrating advanced techniques, innovative technology, and extensive expertise. Our dedication ensures that your specific needs are met with premium molybdenum tungsten alloy solutions.

Expertise and Experience: With over a decade in the industry, we combine cutting-edge technology with deep expertise to deliver top-tier molybdenum tungsten alloy tailored to your exact specifications.

Custom Solutions: We provide fully customized solutions, including unique sizes, shapes, and coatings, to meet precise performance requirements.

Unmatched Quality: Committed to superior manufacturing, we guarantee each molybdenum tungsten alloy product delivers exceptional performance, longevity, and reliability—ensuring excellent value for your investment.

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Why Choose Us?

- Comprehensive Product Range: We offer over 100 products, including tungsten-copper, molybdenum-copper, and other high-specific gravity alloys.

- Global Reach: With exports to the U.S., Germany, South Korea, and more, we have established long-term relationships with customers worldwide.

- Advanced Manufacturing: Our facility houses cutting-edge equipment, including vacuum furnaces and CNC machines, ensuring the highest quality.

- Quality Assurance: We adhere to ISO9001 standards, performing rigorous product testing to guarantee customer satisfaction.

- Experienced Team: Our team consists of experts in non-ferrous metal production, with years of experience in material research and development.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we support custom processing services for tungsten and molybdenum alloys. Whether you need specific alloy compositions, dimensions, or shapes, we can tailor our products to meet your unique requirements. Our OEM/ODM services include material design, prototype development, and full-scale production.

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

FAQ

- What is the minimum order quantity (MOQ)?

- Our MOQ depends on the product, but we generally accept small trial orders for new customers.

- Can you provide samples?

- Yes, we offer samples for most of our products. Contact us to learn more about sample availability.

- What are your payment terms?

- We accept various payment methods, including T/T, L/C, and PayPal, depending on your order size and region.

- How long is the delivery time?

- Delivery times vary by product and order size, but we aim to ship most orders within 4-6 weeks.

- Do you offer custom packaging?

- Yes, we can provide custom packaging solutions to meet your specific needs.

Contact Us

Interested in our tungsten and molybdenum alloys? Contact Shaanxi Peakrise Metal Co., Ltd. for more information. We are eager to work with global buyers to deliver high-quality non-ferrous metal products. Email us at info@peakrisemetal.com today!