molybdenum plate products

W Content: 50% (wt%)

Mo Content: 50% (wt%)

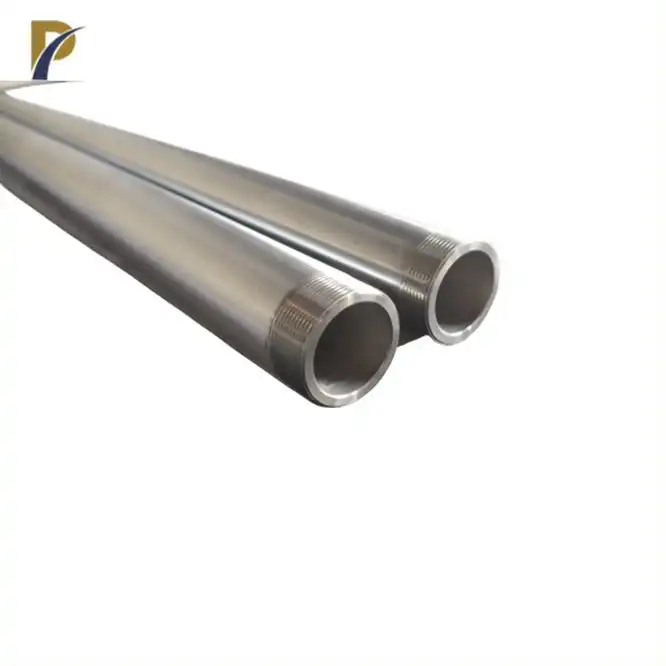

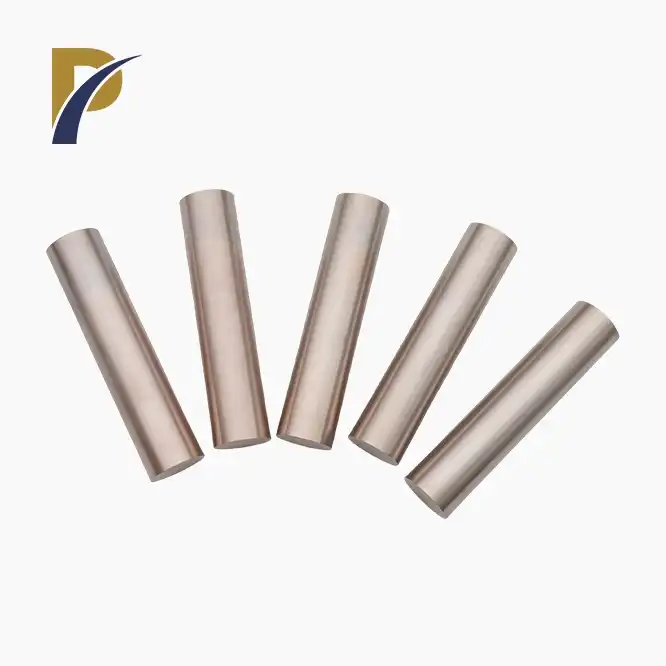

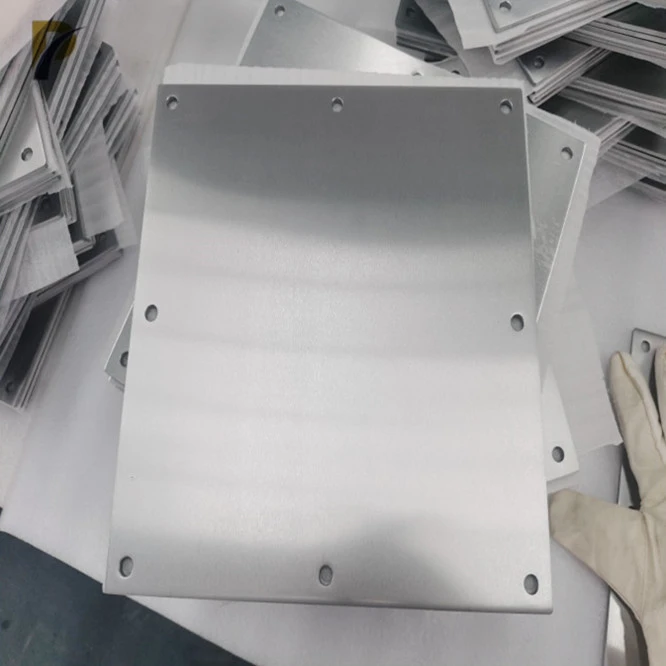

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

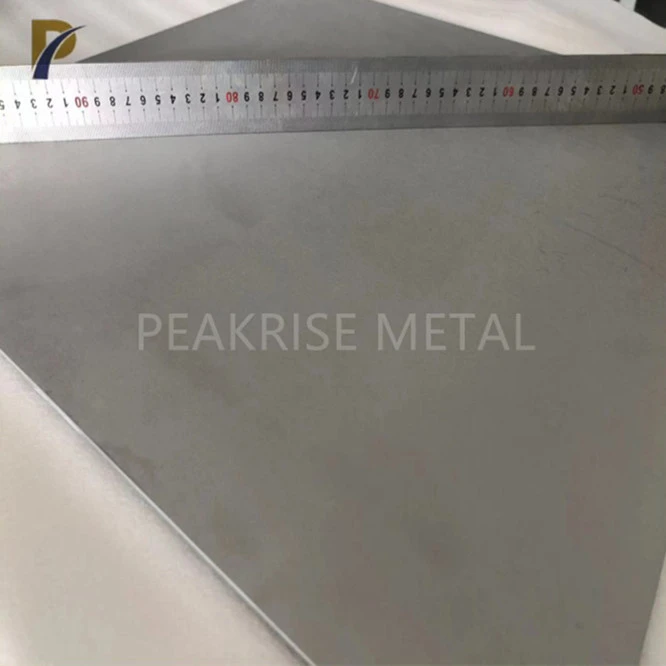

Molybdenum Plate Products – Comprehensive Introduction

Product Introduction

Molybdenum plates are essential in high-temperature applications due to their superior properties, including high melting points, excellent thermal and electrical conductivity, and outstanding mechanical strength. As a professional manufacturer and supplier, Shaanxi Peakrise Metal Co., Ltd. specializes in producing high-quality molybdenum plates, catering to industries that require precise, durable materials, such as aerospace, defense, electronics, and energy. Our molybdenum plates are renowned for their corrosion resistance, stability in extreme temperatures, and machinability, making them an excellent choice for critical components in demanding environments.

Founded over a decade ago, Shaanxi Peakrise Metal Co., Ltd. has grown into a trusted name in the non-ferrous metals industry, supplying products like molybdenum plates to a global market. We maintain an extensive inventory and have state-of-the-art facilities to ensure that we meet the growing demands of our customers worldwide. Our products are highly regarded for their consistency, quality, and precision.

|

|

|

Product Parameters Table

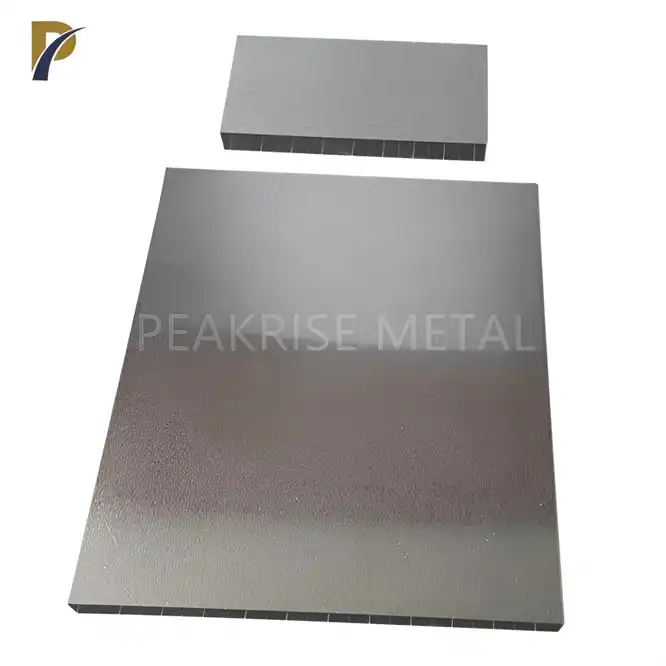

| Name | Thickness(mm) | Width max.(mm) | Length max.(mm) |

| Molybdenum sheet | 0.2~0.3 | 650 | 2500 |

| Molybdenum sheet | 0.3~0.5 | 700 | 3000 |

| Molybdenum sheet | 0.5~1.0 | 750 | 3500 |

| Molybdenum sheet | 1.0~2.0 | 650 | 3500 |

| Molybdenum plate | 2.0~3.0 | 600 | 3000 |

| Molybdenum plate | >3.0 | 600 | L |

Other sizes, welcome to consult, various sizes can be produced according to your requirements.

Additional Parameters for Custom Specifications:

| Parameter | Standard Specification | Custom Range |

|---|---|---|

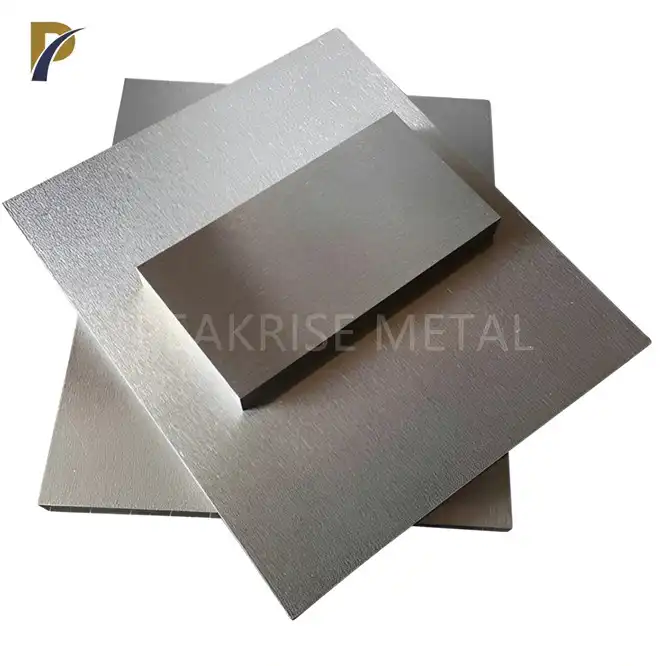

| Surface Finish | Polished, Ground, or Customized | Customized |

| Flatness | ≤ 1% of overall length | Adjustable |

| Tolerance | As per ASTM standards | Customizable |

Physical and Mechanical Properties

Molybdenum plates have impressive mechanical and physical properties that set them apart from other materials used in high-temperature environments.

- High Melting Point: With a melting point of 2620°C, molybdenum plates are ideal for applications that operate in extreme heat.

- Low Thermal Expansion: This ensures dimensional stability even in fluctuating temperatures.

- High Electrical Conductivity: Molybdenum is known for its excellent electrical conductivity, making it suitable for electronic applications.

- Corrosion Resistance: Molybdenum resists most acids and bases, ensuring longevity in harsh environments.

- Excellent Machinability: Despite its strength, molybdenum can be easily machined into complex shapes.

| Quantitative analysis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | N | Mg | Fe | Sn | Al | Cd | Ca | Bi | Si | P | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | Ni | Sb | Pb | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Functions

Molybdenum plates serve a variety of functions in industrial applications, thanks to their unique properties:

- High-Temperature Applications: Molybdenum's high melting point makes it suitable for applications such as furnace components, structural parts, and heating elements.

- Corrosion Resistance: Its ability to resist corrosion ensures long-term reliability in chemical processing and corrosive environments.

- Electrical Applications: Molybdenum plates are often used in the electronics industry for wiring, switches, and conductive plates.

- Machining and Tooling: Due to its hardness and resistance to deformation, molybdenum is ideal for producing parts that endure mechanical wear.

- Thermal Management: Its high thermal conductivity allows for effective heat dissipation, essential in electronics and power generation sectors.

Product Applications

Molybdenum plates are widely used across various industries, each application leveraging the unique attributes of the material:

- Aerospace: Used in the construction of missile and aircraft parts that must withstand high heat and stress.

- Electronics: Applied in the manufacture of semiconductors, LCD screens, and solar panels due to molybdenum's conductivity and heat dissipation properties.

- Energy Production: Molybdenum is essential in nuclear reactors and other high-temperature energy processes, where material strength and stability are critical.

- Defense Industry: Molybdenum plates contribute to the development of military-grade armor and weapons due to their durability and resistance to thermal shock.

- Furnace Manufacturing: Components such as heating elements and structural supports in furnaces rely on molybdenum's high melting point and thermal stability.

- Chemical Industry: The corrosion-resistant properties of molybdenum make it valuable in the production of chemical containers and pipelines.

|

|

Product Process and Production Flow

The production of molybdenum plates at Shaanxi Peakrise Metal Co., Ltd. follows stringent quality control measures to ensure top-grade output:

- Raw Material Selection: High-purity molybdenum ore is selected for production, ensuring a final product that meets strict purity standards.

- Sintering: Molybdenum powder is compressed and sintered at high temperatures in our advanced intermediate frequency sintering furnace.

- Hot Rolling: The sintered plates are subjected to hot rolling, which enhances their mechanical properties and reduces internal stresses.

- Annealing: Vacuum annealing at controlled temperatures improves the material’s ductility, making it easier to machine and process.

- Surface Treatment: Depending on customer specifications, the plates are polished or ground to meet desired surface finish requirements.

- Final Inspection: Every plate undergoes a rigorous inspection process, including dimensional checks, surface quality assessment, and physical property testing.

|

|

|

|

Our Factory

At Shaanxi Peakrise Metal Co., Ltd., our production facilities are equipped with cutting-edge technology to ensure efficient and high-quality production. We operate multiple furnaces, including vacuum arc melting and plasma electron beam melting furnaces, as well as various milling, welding, and rolling machines to handle large-scale production.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We offer a range of packaging options to ensure the safe transport of our molybdenum plates:

- Wooden Packaging: For heavy or large plates, ensuring structural integrity during transport.

- Carton Packaging: Ideal for smaller plates and samples.

- Foam Filling: Added protection against impact during shipping.

- Waterproof and Moisture-Proof Packaging: Essential for shipments to humid or coastal regions.

- Custom Packaging: Tailored solutions to meet client-specific requirements.

Logistics options include:

- Sea Freight: Cost-effective for bulk international shipments.

- Air Freight: For urgent deliveries requiring fast transit times.

- Land Transport: For regional deliveries within China.

- Multimodal Transport: Combining sea, land, and air for complex shipping needs.

- Courier Services: For sample shipments or smaller orders.

|

|

|

|

|

|

|

|

Why Choose Us?

- Experience: Over a decade of expertise in non-ferrous metal production.

- Global Reach: Our products are exported to multiple countries, including the USA, Germany, and Australia.

- Quality Control: ISO 9001-certified, ensuring consistent product quality.

- Innovation: Continuous R&D to improve product performance and meet evolving customer needs.

- Customer Satisfaction: Long-term partnerships built on trust, reliability, and service excellence.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM and ODM services, providing customized molybdenum plates to meet specific industry requirements. From tailored dimensions to specialized surface treatments, we can adjust our products to fit your exact needs.

- What is the maximum thickness of the molybdenum plate?

- We can provide molybdenum plates with thicknesses up to 100 mm.

- Can you provide custom dimensions?

- Yes, we offer custom sizes to meet your project’s specifications.

- What is the purity of your molybdenum plates?

- Our plates are ≥ 99.95% pure.

- Do you offer samples?

- Yes, we provide samples for testing and evaluation purposes.

- How do you ensure product quality?

- Every batch undergoes stringent quality control checks in line with ISO 9001 standards.

Contact Us (CTA)

Looking for high-quality molybdenum plates? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com to discuss your project needs. Our team is ready to provide top-tier solutions tailored to your specifications.