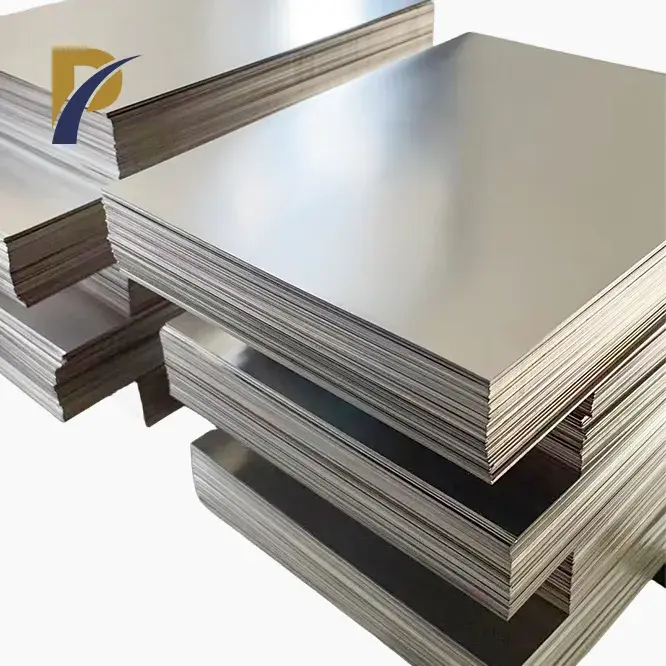

99.97% molybdenum plate

W Content: 50% (wt%)

Mo Content: 50% (wt%)

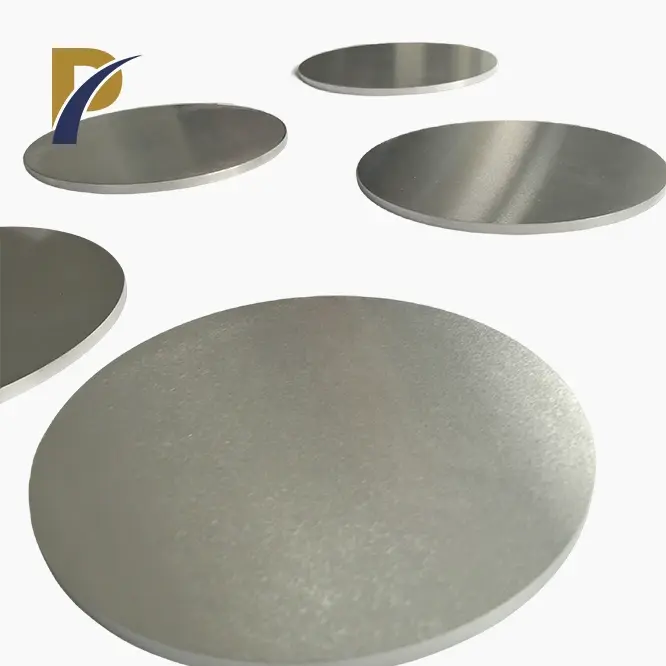

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

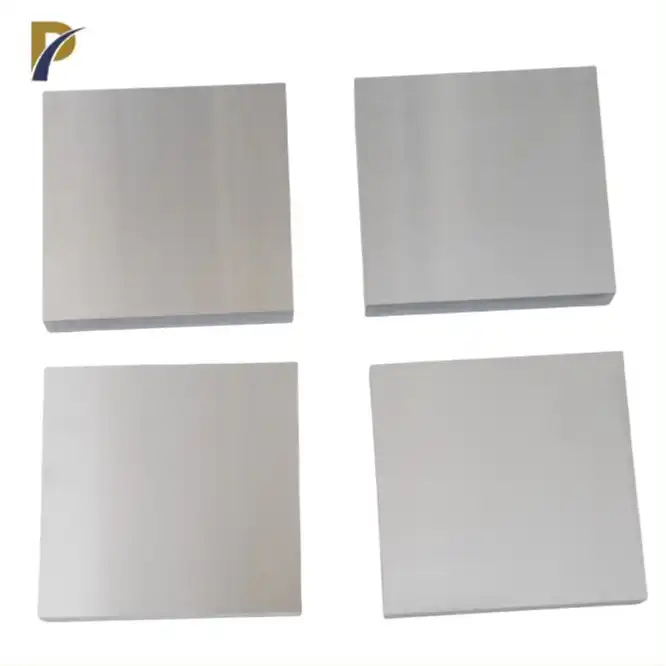

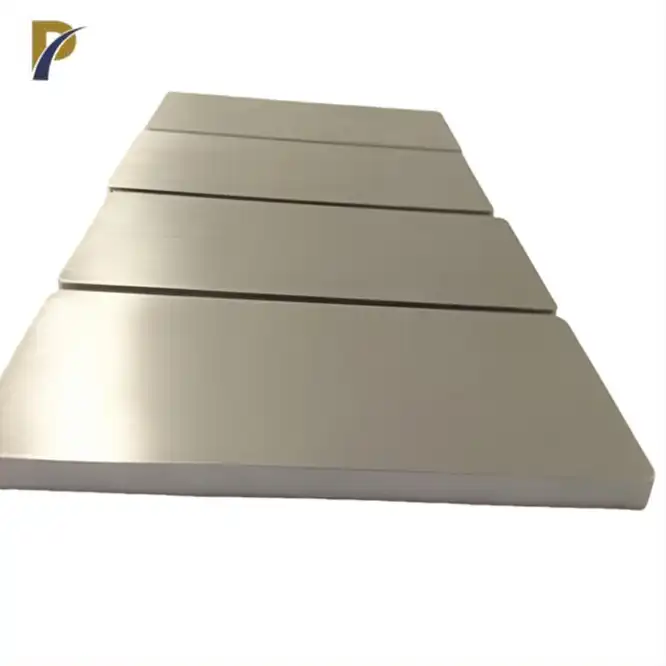

99.97% Molybdenum Plate Product Introduction for Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

99.97% Molybdenum plates (Mo plates) are highly sought after in industries where high temperature strength, thermal conductivity, and low thermal expansion are critical. With a melting point of 2,623°C and remarkable resistance to thermal creep, molybdenum plates are ideal for applications such as furnace construction, aerospace, defense, and energy sectors. As a leading manufacturer and supplier of molybdenum plates, Shaanxi Peakrise Metal Co., Ltd. is committed to delivering top-tier Mo plates tailored to your exact needs. Our extensive production capabilities and rich experience in the non-ferrous metal industry allow us to ensure consistent quality, precision, and material performance in every batch.

Our Mo plates exhibit high purity levels, outstanding machinability, and reliable mechanical properties that make them indispensable in various demanding applications. Having served global markets, we are your trusted partner for high-quality molybdenum solutions. Shaanxi Peakrise Metal Co., Ltd. supplies molybdenum plates in various thicknesses and sizes, with custom specifications available to meet your specific requirements.

Product Parameters Table

| Product Name | Molybdenum plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tensile strength | 610 Mpa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Elongation | ≥10% | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity | ≥99.95%,≥99.97%, | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Size | TK 0.1~80mm*W 10~700mm*L 30~3000mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Use temperature | 1800°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Highest temperature | 2200°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quantitative analysis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Cd | Ca | P | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | N | Sb | Sn | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

Product Functions

- High-Temperature Resistance: Molybdenum plates maintain their strength and structural integrity even under extreme temperatures, making them essential in high-temperature furnace components and aerospace applications.

- Low Thermal Expansion: The low coefficient of thermal expansion allows Mo plates to minimize dimensional changes, ensuring stability in precision manufacturing.

- Corrosion Resistance: Molybdenum’s resistance to corrosion and chemical reactivity in high-temperature environments extends the lifespan of the material in aggressive atmospheres.

- Excellent Machinability: Mo plates are easy to machine, which allows for detailed and precise part production without compromising the mechanical properties.

- Thermal and Electrical Conductivity: Mo plates offer excellent thermal and electrical conductivity, making them useful in electronics and power generation sectors.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

Molybdenum plates are widely used in industries that demand materials capable of withstanding extreme conditions. The following are key applications:

- Furnace Construction: Used as heat shields, liners, and supports in high-temperature furnaces due to their exceptional thermal and mechanical properties.

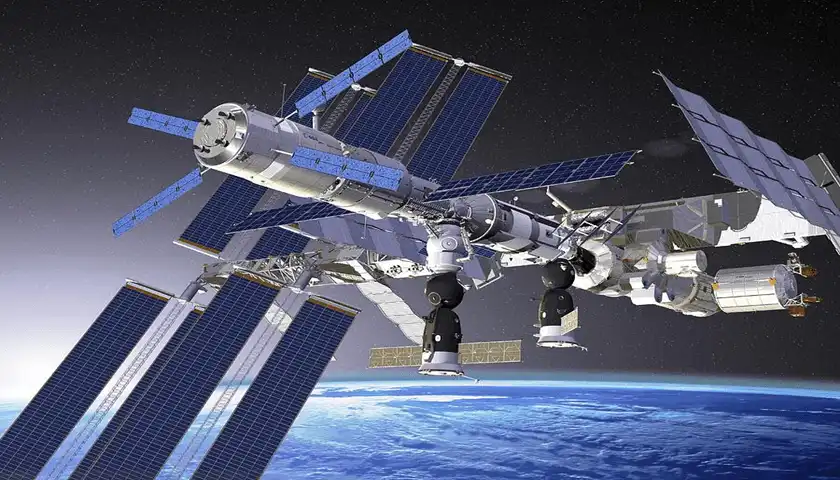

- Aerospace and Defense: Mo plates are employed in missile and spacecraft parts, where they endure extreme heat and mechanical stress.

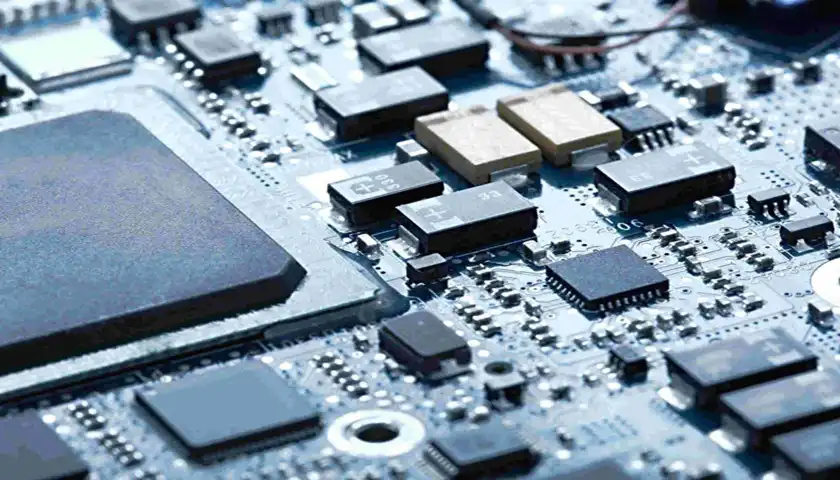

- Semiconductor Manufacturing: Their thermal conductivity and stability are ideal for semiconductor fabrication equipment and solar cell manufacturing.

- Energy Industry: Molybdenum plates find application in nuclear power generation and other energy sectors, offering durability in extreme environments.

- Electronics: Mo plates serve as components in X-ray tubes, heat sinks, and other electronic devices that require both strength and conductivity.

|

|

|

Product Process and Production Flow

The production of molybdenum plates at Shaanxi Peakrise Metal Co., Ltd. follows a carefully controlled process to ensure quality and consistency:

- Raw Material Selection: High-purity molybdenum powder is sourced and tested for chemical composition.

- Powder Metallurgy: The molybdenum powder is compacted and sintered at high temperatures in an intermediate frequency sintering furnace.

- Rolling: The sintered molybdenum is hot-rolled and then cold-rolled to achieve the desired thickness and surface finish.

- Annealing: The plates are heat-treated in a vacuum annealing furnace to improve ductility and remove residual stresses.

- Cutting and Surface Treatment: Precision cutting is performed using laser cutters, followed by polishing or alkali washing for a smooth finish.

- Inspection: Each plate undergoes rigorous quality inspection for flatness, thickness, and surface quality before packaging.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility equipped with a wide range of advanced production machinery, including vacuum arc melting furnaces, rolling mills, CNC machines, and plasma welding systems. Our factory adheres to ISO 9001 standards, ensuring that every step of the production process meets international quality requirements. We also maintain a significant inventory of raw materials and standard parts, allowing us to offer fast turnaround times and flexible production schedules to meet the needs of our global customers.

|

|

|

|

Logistics and Packaging

- Packaging: We offer various packaging options tailored to protect the molybdenum plates during shipping:

- Wooden crates

- Carton boxes

- Foam-filled protective layers

- Waterproof and moisture-proof packaging

- Custom packaging solutions compliant with international shipping standards

- Logistics: We provide flexible shipping options to meet your delivery timelines, including:

- Sea freight

- Air freight

- Land transportation

- Multimodal transport

- Courier services for smaller shipments

|

|

|

|

|

|

|

|

Why Choose Us?

- Rich Industry Experience: With over a decade of experience in the non-ferrous metal industry, we have the expertise to provide high-quality molybdenum products.

- Comprehensive Manufacturing Capabilities: Our facility includes advanced equipment and technology, allowing us to offer a wide range of molybdenum plate specifications.

- International Reach: We export to markets worldwide, including the United States, Germany, South Korea, and more.

- Customization: We offer OEM and ODM services to meet the specific needs of our clients, from custom sizes to special material treatments.

- Commitment to Quality: Our ISO 9001-certified quality control system ensures that every product we deliver meets the highest standards.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. supports OEM and ODM services for molybdenum plates. We collaborate closely with our customers to provide custom processing and manufacturing solutions. Whether you require specific dimensions, finishes, or packaging, we can tailor our products to meet your needs.

|

|

FAQ

- What is the maximum thickness you can provide for molybdenum plates?

- We can provide molybdenum plates with a maximum thickness of 50mm.

- Do you offer custom dimensions?

- Yes, we offer fully customizable molybdenum plates based on your requirements.

- What is the typical lead time for orders?

- Lead times depend on the order size and specifications but typically range from 2 to 4 weeks.

- Are your molybdenum plates suitable for high-temperature applications?

- Yes, our molybdenum plates are specifically designed to withstand extreme temperatures and high-stress environments.

- Do you provide certifications with your products?

- Yes, all of our products come with material certification, and additional testing certificates are available upon request.

Contact Us

Looking for high-quality molybdenum plates? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com to learn more about our products and services. We look forward to partnering with you for all your molybdenum needs.

YOU MAY LIKE

-

VIEW MOREmolybdenum high temperature alloy tzm rod

VIEW MOREmolybdenum high temperature alloy tzm rod -

VIEW MOREmolybdenum alloy strip/foil

VIEW MOREmolybdenum alloy strip/foil -

VIEW MOREmolybdenum wires

VIEW MOREmolybdenum wires -

VIEW MOREsilicon molybdenum rods heating element

VIEW MOREsilicon molybdenum rods heating element -

VIEW MOREtungsten welding electrodes

VIEW MOREtungsten welding electrodes -

VIEW MOREtungsten copper alloy rod

VIEW MOREtungsten copper alloy rod -

VIEW MOREtantalum seamless pipe tube

VIEW MOREtantalum seamless pipe tube -

VIEW MOREcustom tantalum rings

VIEW MOREcustom tantalum rings

_1734662688572.webp)

_1734662688605.webp)