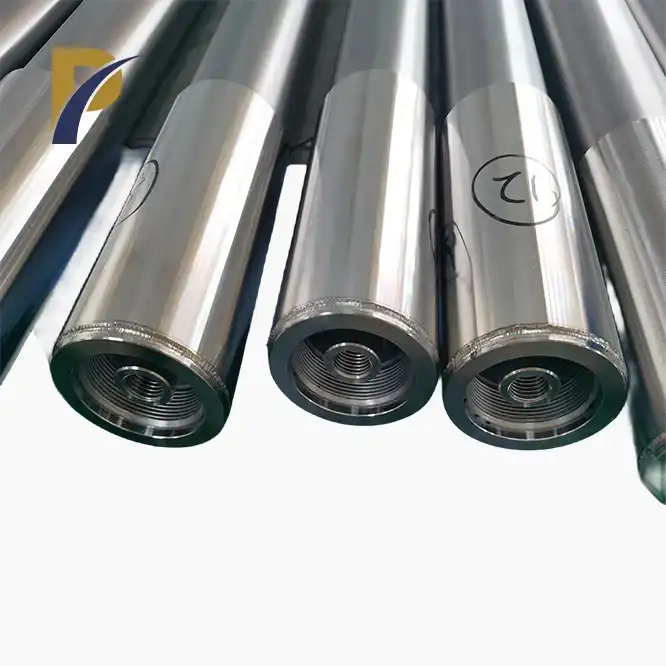

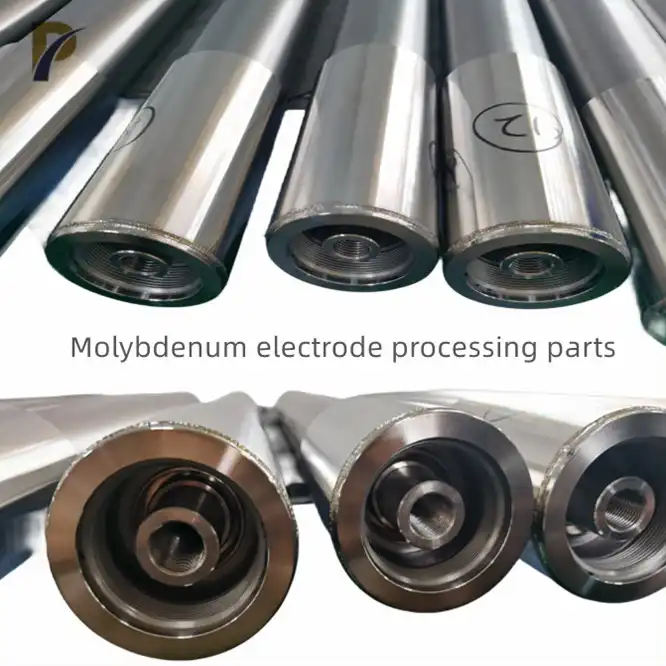

NMP (N-methylpyrrolidone) damage-resistant molybdenum electrode

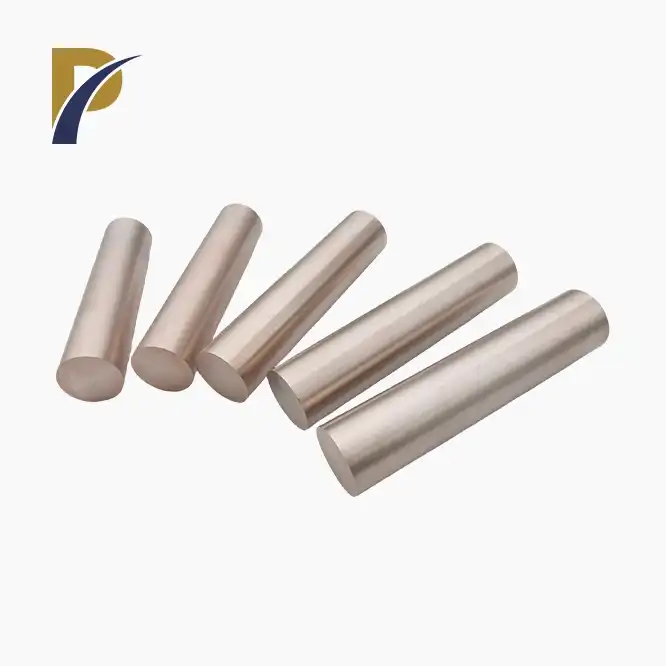

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

Product Introduction

Molybdenum electrodes are integral in various industrial applications due to their high melting point, electrical conductivity, and resistance to corrosion. The NMP (N-methylpyrrolidone) damage-resistant molybdenum electrode from Shaanxi Peakrise Metal Co., Ltd. is designed to withstand harsh conditions while maintaining superior performance in production processes that involve high temperatures and chemical exposures. These electrodes are widely used in glass manufacturing, electronics, and chemical processing industries.

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of NMP damage-resistant molybdenum electrodes, specializing in the production and customization of high-quality molybdenum products for global clients. With over a decade of experience in non-ferrous metal production, we have refined our production methods and materials to deliver electrodes that meet the stringent demands of modern industrial applications. Our products are known for their durability, efficiency, and long-lasting performance, making them the preferred choice for companies in need of reliable electrodes in high-temperature and chemically aggressive environments.

Product Parameters Table

| Parameter | Value |

|---|---|

| Purity (%) | ≥99.95% |

| Density (g/cm³) | 10.2 |

| Melting Point (°C) | 2620 |

| Electrical Conductivity | 18.7 MS/m |

| Thermal Conductivity (W/mK) | 138 |

| Hardness (HV) | 240 |

| Tensile Strength (MPa) | 550 |

|

High Purity 99.95% Molybdenum Electrode Of Glass Electric Melting Furnace: |

|||||

| Dia [mm] |

tolerance [mm] |

length [mm] |

Surface | Straightness [per m] |

Approx weight [kg/m] |

| 4.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.128 |

| 10.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.801 |

| 20.00 | +/- 0.020 | 2000 | polished | <2.5 | 3.204 |

| 25.00 | +/- 0.040 | 2000 | polished | <2.5 | 5.007 |

| 30.00 | +/- 0.300 | 2000 | Polished | <1.5 | 7.210 |

| 40.00 | +/- 0.300 | 2000 | Polished | <1.5 | 12.818 |

| 50.00 | +/- 0.400 | 2000 | Polished | <1.5 | 20.654 |

| 60.00 | +/- 0.400 | 2000 | Polished | <1.5 | 28.840 |

| 63.50 | +/- 0.400 | 2000 | Polished | <1.5 | 32.303 |

| 70.00 | +/- 0.400 | 2000 | Polished | <1.5 | 39.254 |

| 80.00 | +/- 1.000 | 2000 | Polished | <2.5 | 51.271 |

| 90.00 | +/- 1.000 | 2000 | Polished | <2.5 | 64.890 |

| 100.00 | +/- 1.000 | 2000 | Polished | <2.5 | 80.111 |

| 120.00 | +/- 2.000 | 2000 | Polished | <2.5 | 115.359 |

|

|

|

Product Functions

- High-Temperature Stability: Molybdenum electrodes maintain their structural integrity at temperatures exceeding 2600°C, ensuring reliable performance in high-heat processes.

- Corrosion Resistance: NMP damage-resistant molybdenum electrodes are highly resistant to corrosion, particularly in environments involving harsh chemicals or solvents like N-methylpyrrolidone.

- Superior Electrical Conductivity: With an electrical conductivity of 18.7 MS/m, these electrodes provide efficient energy transfer, making them ideal for applications in electronics and energy-intensive industries.

- Oxidation Resistance: The electrodes' ability to resist oxidation at elevated temperatures prolongs their service life, reducing maintenance costs and downtime.

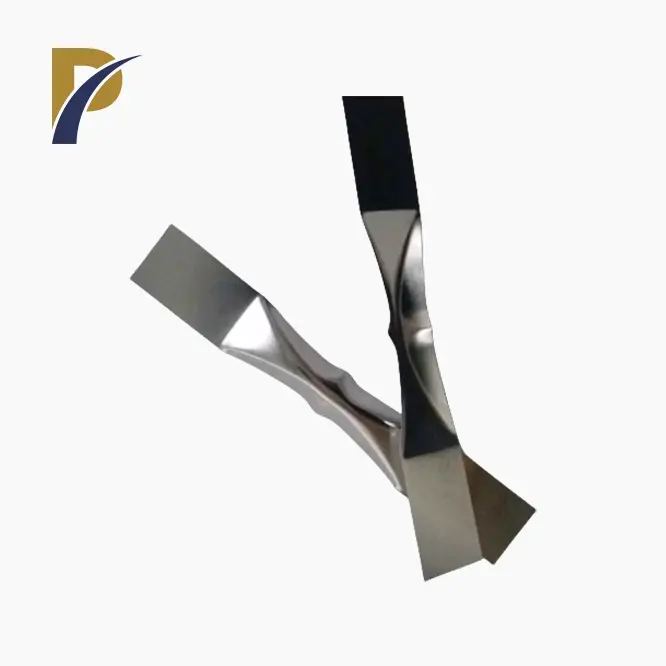

- Customizable Dimensions: We offer a wide range of customizable sizes and shapes, ensuring that our molybdenum electrodes fit perfectly into any industrial application.

|

|

|

|

Product Applications

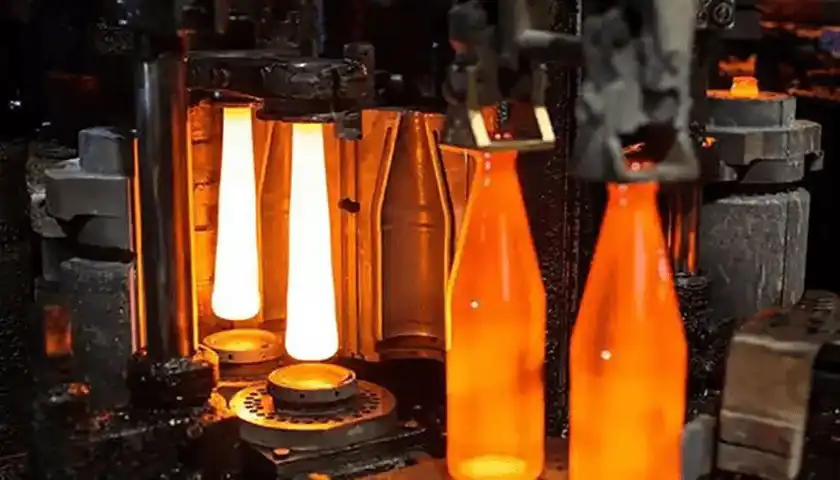

- Glass Manufacturing: Molybdenum electrodes are extensively used in the glass industry for melting and shaping processes. Their resistance to high temperatures and corrosion makes them ideal for producing high-quality glass products.

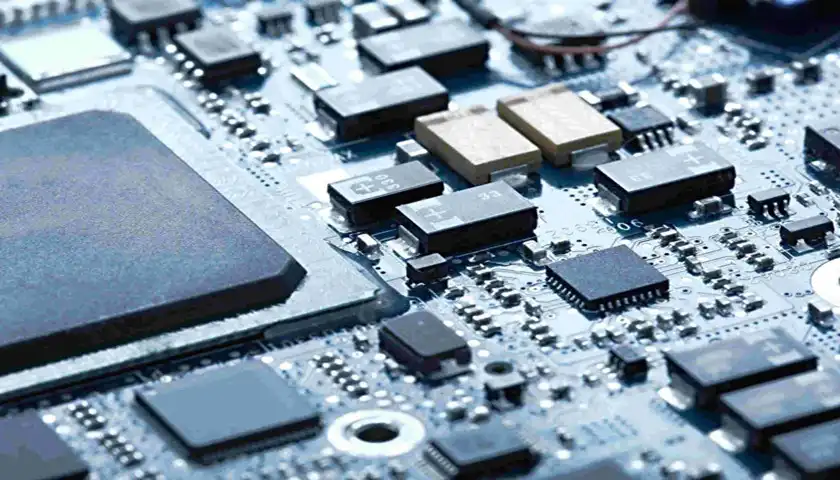

- Electronics Production: Due to their excellent electrical conductivity, molybdenum electrodes are used in the manufacturing of semiconductors, LCD displays, and other electronics where precision and reliability are essential.

- Chemical Processing: NMP-resistant molybdenum electrodes are a crucial component in chemical plants where high temperatures and exposure to corrosive chemicals are common. They ensure the efficient functioning of reactors and other chemical processing equipment.

- Metallurgical Applications: In metallurgy, these electrodes are employed in the production of alloys and metals that require high-temperature processing, ensuring consistent quality and productivity.

|

|

|

Product Process and Production Flow

The production of NMP damage-resistant molybdenum electrodes follows a rigorous process designed to ensure the highest standards of quality:

- Raw Material Selection: We use high-purity molybdenum (≥99.95%) to ensure optimal performance and longevity.

- Vacuum Melting: The raw molybdenum is subjected to vacuum arc melting to remove impurities and achieve the desired density and strength.

- Forging and Rolling: The material is then forged and rolled to achieve the required size, shape, and surface finish.

- Machining: Precision machining ensures that each electrode meets the specific dimensional and flatness requirements of the customer.

- Quality Testing: Each electrode undergoes stringent testing, including surface finish analysis, dimensional accuracy checks, and electrical conductivity tests.

- Packaging and Shipping: After passing all quality checks, the electrodes are carefully packaged for safe transport to their destination.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility equipped with advanced production equipment. Our factory features vacuum arc melting furnaces, laser cutters, plasma welding systems, and CNC machines, ensuring precision and consistency across all production runs. We also have a fully equipped R&D department focused on material innovation and process improvements.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Crate Packaging: For large, heavy-duty electrodes, ensuring protection during long-distance shipping.

- Carton and Foam Packaging: Suitable for smaller or more fragile components, providing cushioning and protection from impact.

- Waterproof and Moisture-Proof Packaging: Critical for maintaining product quality during overseas shipping where humidity levels may vary.

- Custom Packaging: Tailored solutions available based on customer requirements, ensuring all products meet international shipping standards.

|

|

|

|

|

|

|

|

Why Choose Us?

- Industry Expertise: With over a decade of experience in producing high-quality non-ferrous metals, including molybdenum electrodes, we are a trusted partner for global customers.

- Comprehensive Services: We offer full customization, from material composition to final dimensions, to meet specific industrial needs.

- Global Reach: Our products are exported to countries including the USA, Germany, South Korea, and Australia, backed by strong customer feedback and loyalty.

- Advanced Manufacturing Capabilities: We utilize cutting-edge technology, including vacuum arc melting and precision machining, to produce top-tier molybdenum electrodes.

- Quality Assurance: All our products adhere to stringent ISO 9001 quality standards, ensuring consistency, performance, and safety.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. supports OEM/ODM services, allowing clients to customize molybdenum electrode products according to their specific requirements. Our dedicated team collaborates closely with customers to ensure all products meet precise technical and functional specifications.

|

|

|

FAQ

-

What is the purity of the molybdenum used? Our molybdenum electrodes are made with a purity level of ≥99.95%, ensuring excellent performance and longevity.

-

Can the dimensions be customized? Yes, we offer full customization for electrode size and shape to fit your specific application needs.

-

What is the typical lead time for orders? Lead times vary based on order size and customization requirements but typically range from 4 to 6 weeks.

-

Are these electrodes suitable for use in high-temperature environments? Yes, our electrodes are specifically designed for high-temperature applications, with a melting point exceeding 2600°C.

-

What shipping options are available? We offer sea, air, land, and multimodal transportation services to ensure safe and timely delivery to your location.

Logistics

- Sea transport

- Air transport

- Land transport

- Multimodal transport

- Express courier services

Contact Us

Ready to learn more or place an order? Contact us at info@peakrisemetal.com to discuss your requirements. We are committed to providing the highest quality NMP damage-resistant molybdenum electrodes to meet your industrial needs.