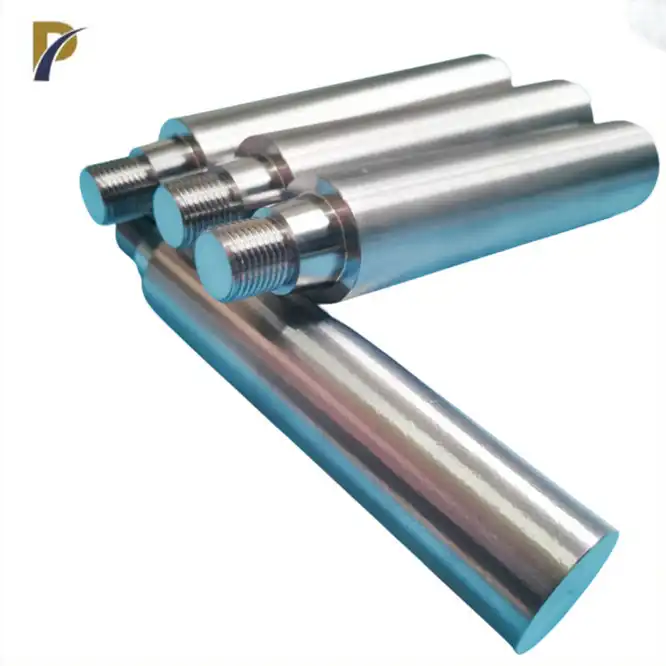

molybdenum rhenium electrodes

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

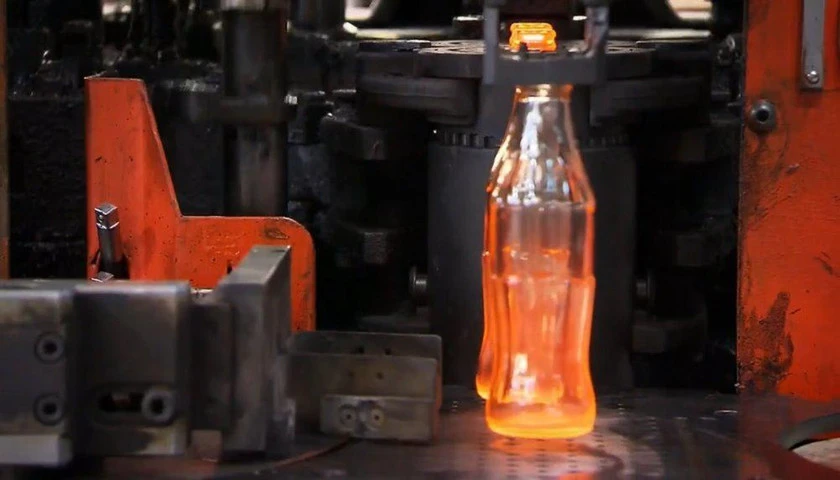

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

Product Introduction

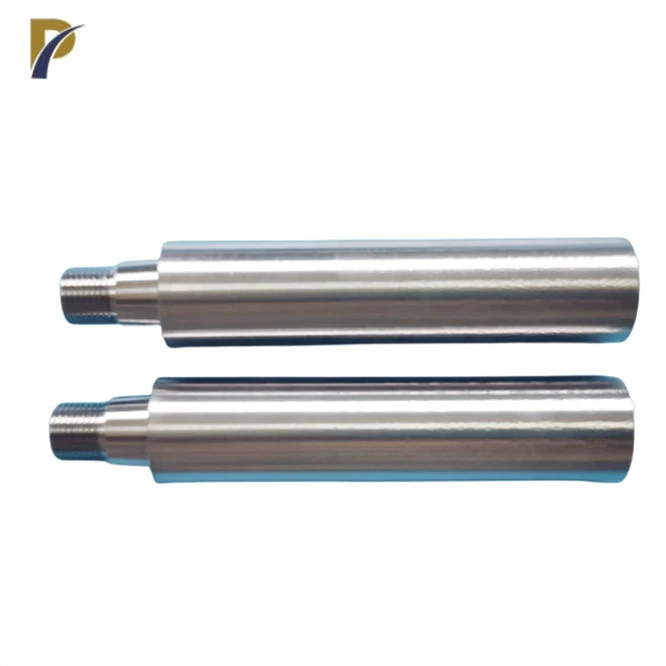

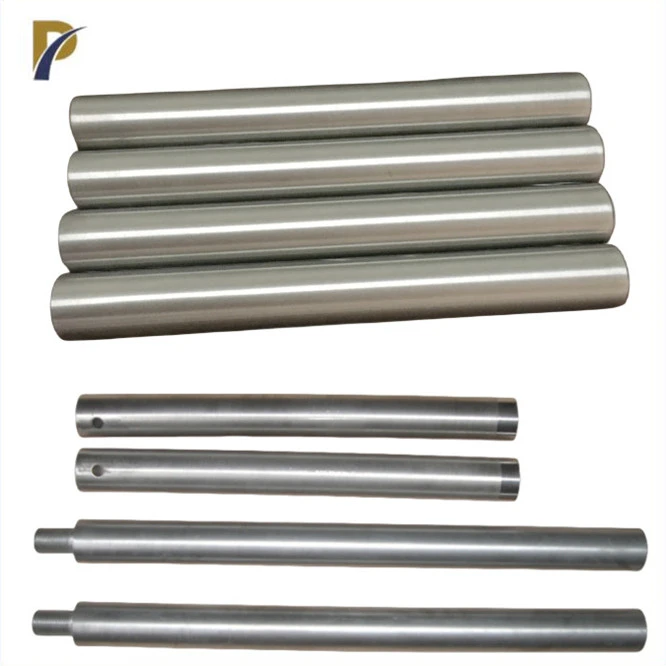

Molybdenum Rhenium (MoRe) Electrodes are advanced high-performance electrodes designed for demanding applications in the glass, semiconductor, and industrial heating industries. Engineered with a precise composition of molybdenum and rhenium, these electrodes exhibit exceptional thermal conductivity, superior mechanical strength, and outstanding resistance to high temperatures and oxidation.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Composition | Molybdenum-Rhenium (MoRe) |

| Purity | Mo ≥ 99.97%, Re ≥ 26% |

| Diameter Range | 4mm - 120mm |

| Length | ≤ 2500mm |

| Standard Compliance | ASTM B387 |

| Density | ≥ 10.2 g/cm³ |

| Melting Point | ~ 2,620°C |

| Surface Finish | Polished |

| Tolerance | ±0.02mm - ±2.00mm |

| Electrical Conductivity | High |

| Oxidation Resistance | Excellent |

|

|

|

Features of molybdenum electrodes

High melting point, excellent conductivity, corrosion resistance, durability, high thermal conductivity, stability, efficient glass melting, reliable performance.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Precision engineered molybdenum electrodes to meet your specific needs!

At Peakrise Metal, your specific needs are our top priority. With over a decade of dedication, we expertly convert your intricate ideas into practical solutions using our precision-engineered molybdenum electrodes. From initial design to detailed specification modifications, each step of our manufacturing process is customized to fulfill your exact requirements.

The following customizations can be made when purchasing molybdenum electrodes:

- Size and shape: Customize the length, diameter and shape of the electrode according to specific application requirements to adapt to different equipment and operating conditions.

- Purity: Provide molybdenum materials with different purity levels according to customer requirements to meet the performance requirements of specific applications.

- Coating treatment: Add specific coatings to the electrode, such as anti-oxidation coating or conductive coating, to improve the performance and life of the electrode in specific environments.

- Connection method: Customize the connection method of the electrode according to the installation requirements of the equipment, such as threaded connection, flange connection, etc., to ensure convenient and stable installation.

- Packaging: Provide customized packaging solutions according to transportation and storage requirements to ensure the safety and integrity of the electrode during transportation.

Why choose molybdenum electrodes from Peakrise Metal?

At Peakrise Metal, we represent the highest industry standards through a perfect combination of advanced techniques, innovative technology, and unmatched expertise. Our steadfast commitment guarantees that your specific needs are expertly addressed with top-quality molybdenum electrode solutions.

Expertise and Experience: With over a decade in the industry, Peakrise Metal combines advanced technology and deep expertise to deliver high-quality molybdenum electrodes tailored to your precise needs.

Custom Solutions: We offer personalized solutions, including custom sizes, shapes, and coatings, ensuring our molybdenum electrodes meet the exact specifications and performance requirements of your application.

Unmatched Quality: Our commitment to superior manufacturing standards ensures that each molybdenum electrode delivers exceptional performance, durability, and reliability, providing excellent value for your investment.

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Applications:

Glass Industry: Utilized in high-temperature glass melting and refining processes, including optical glass and specialty glass manufacturing.

Semiconductor Industry: Ideal for plasma etching, ion implantation, and thin-film deposition applications.

Vacuum & Aerospace Technologies: Employed in high-temperature heating elements, thermionic emitters, and propulsion systems.

Medical & Research Equipment: Used in advanced laboratory applications and high-temperature research environments.

|

|

Manufacturing Process:

Powder Metallurgy: High-purity molybdenum and rhenium powders are precisely blended.

Compaction & Sintering: The mixture is compacted under high pressure and sintered in a controlled environment.

Hot Rolling & Forging: Enhances density and mechanical properties.

Precision Machining: Electrodes are precisely cut, ground, and polished to meet stringent dimensional tolerances.

Quality Inspection: Multiple non-destructive tests (NDT) ensure defect-free electrodes.

Quality Assurance:

ISO 9001 Certified Manufacturing

Multiple NDT Inspections (Ultrasonic & Radiographic Testing)

Stringent Material Purity Testing

Guaranteed Dimensional Accuracy & Surface Finish

Packaging & Logistics:

Packaging: Securely packed in plywood crates with foam protection to prevent damage.

Lead Time: 7-10 business days (depending on order volume).

Shipping: Global delivery via air/sea freight with full tracking.

OEM & Customization Services:

We offer OEM and custom manufacturing services for Molybdenum Rhenium Electrodes. Our engineers work closely with clients to develop solutions tailored to specific industrial needs. Contact us for custom specifications, sizes, and applications.

FAQs

Q1: What is the advantage of rhenium in MoRe electrodes?

A1: Rhenium enhances the ductility, mechanical strength, and oxidation resistance of molybdenum, making it ideal for extreme environments.

Q2: Can you provide custom dimensions for MoRe electrodes?

A2: Yes, we offer customization in size, shape, and composition based on customer requirements.

Q3: How do you ensure quality control?

A3: We implement multiple non-destructive testing (NDT) processes and adhere to ISO 9001 standards to ensure product integrity.

Q4: What is the typical lifespan of these electrodes?

A4: The lifespan depends on the application and operating conditions, but MoRe electrodes are designed for long-term use in high-temperature environments.

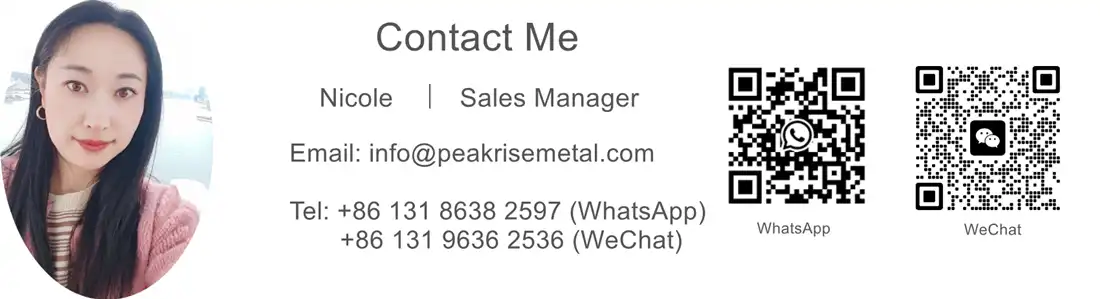

Get the Best Price Today!

For bulk orders or to receive a customized quote, contact us now:

📩 Email: info@peakrisemetal.com

📞 WhatsApp: +8613186382597

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes

VIEW MOREmolybdenum electrodes -

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MORE63 diameter molybdenum electrode

VIEW MORE63 diameter molybdenum electrode -

VIEW MOREmolybdenum lanthanum furnace boats

VIEW MOREmolybdenum lanthanum furnace boats -

VIEW MOREmolybdenum vacuum boat

VIEW MOREmolybdenum vacuum boat -

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREmolybdenum alloy strip foil

VIEW MOREmolybdenum alloy strip foil