Understanding Molybdenum Welding Electrodes

Composition and Properties of Molybdenum

Molybdenum is a refractory metal known for its exceptional properties. It boasts a high melting point of 2,623°C (4,753°F), making it ideal for high-temperature applications. Molybdenum also exhibits excellent thermal and electrical conductivity, low thermal expansion, and remarkable resistance to corrosion and wear.

Manufacturing Process of Molybdenum Electrodes

The production of molybdenum welding electrodes involves a meticulous process. It starts with the extraction of molybdenum from its ores, followed by purification and powder metallurgy techniques. The resulting molybdenum powder is then compressed and sintered to form solid electrodes. This process ensures the consistency and quality of the electrodes.

Types of Molybdenum Electrodes

Molybdenum electrodes come in different grades and compositions to suit diverse welding applications. A few common sorts incorporate immaculate molybdenum electrodes, lanthanum-doped molybdenum electrodes, and thoriated molybdenum electrodes. Each sort offers particular points of interest depending on the welding necessities.

|

|

Key Advantages of Molybdenum Welding Electrodes

Superior Heat Resistance

One of the most significant advantages of molybdenum welding electrodes is their exceptional heat resistance. The high melting point of molybdenum allows these electrodes to maintain their integrity even under extreme temperatures. This property is particularly beneficial in applications involving high-temperature welding, such as in aerospace or nuclear industries.

Enhanced Arc Stability

Molybdenum electrodes give great bend soundness amid welding operations. The steady bend makes a difference keep up exact control over the welding handle, coming about in smoother welds and decreased scatter. This soundness is significant for accomplishing high-quality welds, particularly in basic applications where exactness is vital.

Improved Weld Quality

The utilize of molybdenum welding electrodes regularly leads to progressed weld quality. The electrodes' capacity to keep up a steady circular segment and stand up to tall temperatures contributes to way better infiltration and combination of the welded materials. This comes about in more grounded, more tough welds with less surrenders, upgrading the in general judgment of the welded structure.

Applications and Industries Benefiting from Molybdenum Electrodes

Aerospace and Aviation

The aerospace industry heavily relies on molybdenum welding electrodes for their ability to withstand extreme temperatures and provide high-quality welds. These electrodes are used in the fabrication of aircraft engines, turbines, and other critical components where strength and reliability are essential.

Nuclear Power Generation

In nuclear power plants, molybdenum electrodes play a crucial role in welding operations. Their resistance to corrosion and ability to maintain structural integrity under high temperatures make them ideal for welding reactor components and other critical parts in nuclear facilities.

Electronics and Semiconductor Manufacturing

The gadgets industry benefits from molybdenum electrodes in different applications, counting the generation of semiconductor gadgets. The electrodes' great electrical conductivity and accuracy welding capabilities make them important in fabricating complex electronic components.

|

|

Comparing Molybdenum Electrodes to Other Materials

Molybdenum vs. Tungsten Electrodes

Whereas tungsten anodes are broadly utilized in TIG welding, molybdenum electrodes offer certain points of interest in particular applications. Molybdenum electrodes for the most part have a lower work work, which can lead to simpler circular segment start and progressed circular segment soundness. They moreover tend to be more safe to defilement compared to tungsten terminals.

Molybdenum vs. Carbon Electrodes

In comparison to carbon electrodes, molybdenum electrodes offer superior performance in high-temperature applications. They have a much higher melting point and better resistance to thermal shock, making them more suitable for welding refractory metals and other heat-resistant materials.

Molybdenum vs. Copper Electrodes

Copper terminals are known for their amazing electrical conductivity, but molybdenum anodes beat them in high-temperature applications. Molybdenum's higher softening point and superior resistance to misshapening at hoisted temperatures make it a favored choice for welding operations that include seriously warm.

Best Practices for Using Molybdenum Welding Electrodes

Proper Electrode Preparation

To maximize the benefits of molybdenum welding electrodes, proper preparation is crucial. This includes cleaning the electrode surface, sharpening the tip to the correct angle, and ensuring the electrode is free from contamination. Proper preparation helps maintain arc stability and improves overall weld quality.

Optimizing Welding Parameters

Accomplishing the best comes about with molybdenum electrodes requires cautious alteration of welding parameters. This incorporates setting the adjust amperage, voltage, and protecting gas stream rate. Optimizing these parameters guarantees ideal bend execution and weld quality.

Safety Considerations

When working with molybdenum welding electrodes, it's essential to adhere to proper safety protocols. This includes using appropriate personal protective equipment (PPE), ensuring proper ventilation, and following recommended handling procedures for molybdenum electrodes.

Future Trends and Innovations in Molybdenum Electrode Technology

Advancements in Electrode Composition

Ongoing research is focused on developing new molybdenum alloys and compositions to further enhance the performance of welding electrodes. These innovations aim to improve arc stability, reduce electrode wear, and extend the lifespan of molybdenum electrodes.

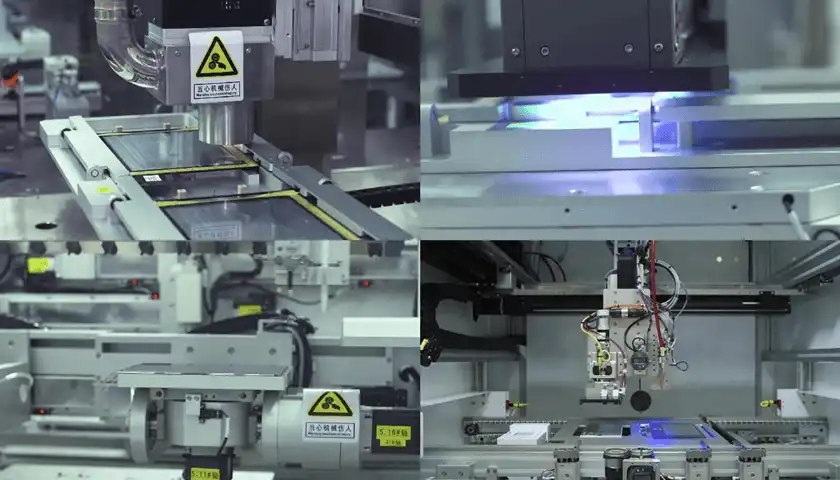

Integration with Automated Welding Systems

As computerized welding frameworks gotten to be more predominant, molybdenum electrodes are being adjusted for utilize in mechanical welding applications. This integration guarantees to make strides welding accuracy and proficiency in high-volume fabricating situations.

Sustainable Manufacturing Processes

The industry is exploring more sustainable methods for producing molybdenum electrodes, including recycling processes and energy-efficient manufacturing techniques. These efforts aim to reduce the environmental impact of electrode production while maintaining product quality.

Conclusion

Molybdenum welding electrodes offer numerous advantages that make them invaluable in various industrial applications. Their superior heat resistance, enhanced arc stability, and ability to produce high-quality welds make them a preferred choice for many welding professionals. As technology advances, we can expect to see further innovations in molybdenum electrode technology, expanding their applications and improving their performance. For industries requiring precision welding in demanding environments, molybdenum electrodes continue to be an excellent choice, providing reliability and efficiency in welding operations.

Contact Us

Are you interested in learning more about molybdenum welding electrodes and how they can benefit your welding operations? Contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com for expert advice and high-quality molybdenum products tailored to your specific needs.