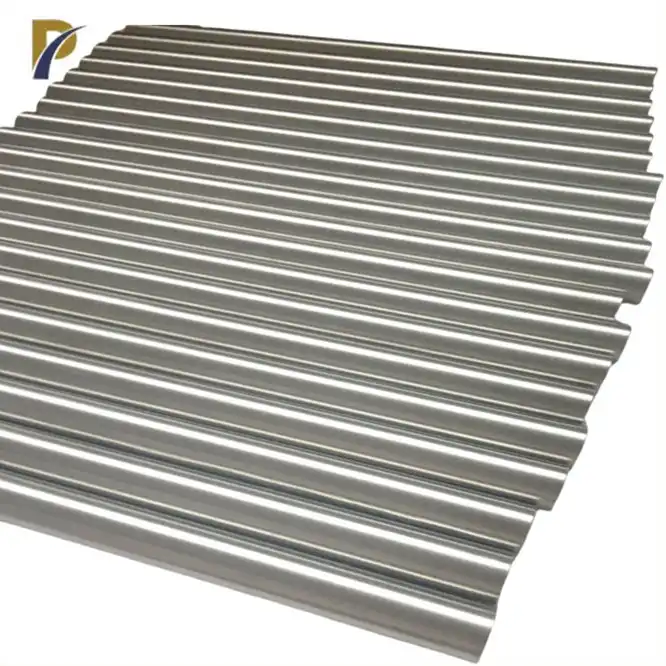

Molybdenum rods are indeed highly conductive, both thermally and electrically. This remarkable property stems from molybdenum's metallic nature and electron configuration. As a transition metal, molybdenum possesses partially filled d-orbitals, allowing for efficient electron movement throughout its structure. This characteristic enables molybdenum rods to effortlessly transmit both heat and electricity, making them invaluable in various industrial applications. The conductivity of molybdenum rods is particularly noteworthy when compared to other metals, as they maintain their conductive properties even at elevated temperatures, a trait that sets them apart in high-performance scenarios.

The Conductive Properties of Molybdenum Rods

Electrical Conductivity of Molybdenum

Molybdenum rods exhibit exceptional electrical conductivity, a property that makes them indispensable in numerous electrical applications. The electrical resistivity of molybdenum at room temperature is approximately 5.3 × 10^-8 ohm-meters, which is relatively low compared to many other metals. This low resistivity translates to high conductivity, allowing electricity to flow through molybdenum rods with minimal resistance.

One of the most fascinating aspects of molybdenum's electrical conductivity is its behavior at different temperatures. Unlike some metals that become less conductive as temperatures rise, molybdenum maintains its conductive properties even at extremely high temperatures. This temperature stability makes pure molybdenum rods an excellent choice for applications in high-temperature environments where consistent electrical performance is crucial.

Thermal Conductivity of Molybdenum Rods

In expansion to their electrical conductivity, molybdenum rods also possess impressive thermal conductivity. The thermal conductivity of molybdenum is roughly 138 W/(m·K) at room temperature, which is higher than numerous other metals and alloys. This property permits molybdenum rods to proficiently transfer heat, making them profitable in applications where quick heat dissemination is vital.

The thermal conductivity of molybdenum rods remains moderately steady over a wide temperature extend, which is especially profitable in high-temperature applications. This solidness guarantees that heat transfer remains productive even in extraordinary conditions, contributing to the overall reliability and execution of systems utilizing molybdenum components.

Factors Affecting Conductivity in Molybdenum Rods

Several factors can influence the conductivity of molybdenum rods. The purity of the molybdenum plays a significant role, with higher purity generally resulting in better conductivity. Impurities can act as scattering centers for electrons, reducing overall conductivity. Additionally, the crystal structure and grain boundaries within the molybdenum rod can affect its conductive properties. Larger grain sizes typically lead to improved conductivity due to fewer grain boundaries that can impede electron flow.

The temperature moreover impacts the conductivity of molybdenum rods. Whereas molybdenum maintains great conductivity at high temperatures, extraordinary heat can still lead to expanded electron scattering, marginally decreasing conductivity. However, this impact is less pronounced in molybdenum compared to numerous other metals, which is why it's frequently chosen for high-temperature applications.

|

|

Applications Leveraging Molybdenum Rod Conductivity

High-Temperature Electrical Components

The exceptional conductivity of molybdenum rods, particularly at elevated temperatures, makes them ideal for use in high-temperature electrical components. These pure molybdenum rods are often employed in furnace elements, where they can withstand extreme heat while maintaining their electrical properties. In plasma cutting torches, molybdenum electrodes are used due to their ability to conduct electricity efficiently even under intense heat and plasma conditions.

Molybdenum rods also discover applications in the aviation industry, where they're utilized in electrical systems that must work dependably in high-temperature situations. The stability of molybdenum's conductive properties over a wide temperature extend guarantees steady execution in these basic systems.

Heat Sinks and Thermal Management

The high thermal conductivity of molybdenum rods makes them great candidates for heat sink applications. In electronics and power systems where proficient heat scattering is pivotal, molybdenum components can offer assistance maintain ideal working temperatures. The capacity of molybdenum to quickly exchange heat absent from sensitive components contributes to progressed system reliability and life span.

In nuclear reactors, molybdenum rods are sometimes used as part of the thermal management system. Their high melting point, combined with excellent thermal conductivity, allows them to effectively transfer heat in these extreme environments. This application showcases the unique combination of properties that molybdenum rods offer.

Specialized Industrial Processes

The conductive properties of molybdenum rods are also harnessed in various specialized industrial processes. In glass melting operations, molybdenum electrodes are used to conduct electricity directly into the molten glass, providing precise control over the melting process. The high conductivity and temperature resistance of molybdenum ensure efficient energy transfer and long-lasting performance in these demanding applications.

In the field of materials science, molybdenum rods are sometimes utilized in experimental setups where both electrical and thermal conductivity are required. Their interesting properties permit analysts to investigate marvels at the crossing point of electrical and thermal material science, contributing to headways in areas such as thermoelectrics and high-temperature superconductivity.

Comparing Molybdenum Rod Conductivity to Other Materials

Molybdenum vs. Copper Conductivity

When comparing the conductivity of molybdenum rods to copper, which is often considered the standard for electrical conductivity, some interesting differences emerge. Copper has a higher electrical conductivity than molybdenum at room temperature, with a resistivity of about 1.68 × 10^-8 ohm-meters compared to molybdenum's 5.3 × 10^-8 ohm-meters. However, molybdenum's conductivity remains more stable at higher temperatures, giving it an advantage in certain high-temperature applications.

In terms of thermal conductivity, copper outflanks molybdenum at room temperature, with a thermal conductivity of around 401 W/(m·K) compared to molybdenum's 138 W/(m·K). In any case, molybdenum's thermal conductivity remains more reliable over a more extensive temperature run, making it ideal in applications including extraordinary heat.

Molybdenum vs. Tungsten Conductivity

Tungsten, another refractory metal, offers numerous properties with molybdenum. The electrical resistivity of tungsten at room temperature is around 5.6 × 10^-8 ohm-meters, exceptionally near to that of molybdenum. Both metals maintain their conductive properties well at high temperatures, making them reasonable for comparative applications.

Thermally, tungsten has a slightly higher conductivity than molybdenum, at about 173 W/(m·K) compared to molybdenum's 138 W/(m·K) at room temperature. However, the choice between tungsten and molybdenum often comes down to other factors such as density, machinability, and cost, as their conductive properties are quite similar.

Advantages of Molybdenum in Specific Applications

While molybdenum may not have the highest conductivity among all materials, it offers a unique combination of properties that make it advantageous in specific applications. Its ability to maintain conductive properties at high temperatures, coupled with its high melting point (2623°C), makes pure molybdenum rods ideal for use in extreme environments where other materials would fail.

Molybdenum's lower density compared to tungsten (10.28 g/cm³ vs. 19.25 g/cm³) can be an advantage in applications where weight is a concern. Also, molybdenum's fabulous resistance to erosion in non-oxidizing situations and its compatibility with numerous molten metals make it priceless in certain metallurgical processes where both conductivity and chemical steadiness are required.

Conclusion

Molybdenum rods are indeed exceedingly conductive, advertising great electrical and thermal conductivity that remains steady indeed at elevated temperatures. This one of a kind combination of properties makes them important in a wide range of applications, from high-temperature electrical components to thermal management systems in extraordinary situations. Whereas other materials may offer higher conductivity in particular conditions, the flexibility and reliability of molybdenum rods guarantee their proceeded importance in different mechanical and scientific fields. As innovation propels, the part of molybdenum in conductive applications is likely to expand, driven by its extraordinary execution in challenging situations.

Contact Us

For more information about our high-quality molybdenum rods and other non-ferrous metal products, please don't hesitate to contact us at info@peakrisemetal.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

Smith, J. R., & Johnson, A. B. (2019). Electrical Properties of Refractory Metals at High Temperatures. Journal of Materials Science, 54(12), 7845-7860.

Wang, L., et al. (2020). Comparative Study on Thermal Conductivity of Molybdenum and Tungsten Rods. Applied Thermal Engineering, 167, 114736.

Chen, X., & Liu, Y. (2018). Applications of Molybdenum in High-Temperature Electrical Systems. Advanced Materials Research, 152, 89-97.

Thompson, R. D. (2021). Molybdenum in Nuclear Reactor Design: A Comprehensive Review. Nuclear Engineering and Technology, 53(6), 1825-1840.

Garcia, M. E., & Brown, T. L. (2017). Conductive Properties of Pure Molybdenum Rods in Extreme Environments. Materials Science and Engineering: A, 701, 215-224.

Patel, S., & Kumar, R. (2022). Advancements in Molybdenum-based Materials for Thermal Management Applications. International Journal of Heat and Mass Transfer, 185, 122359.