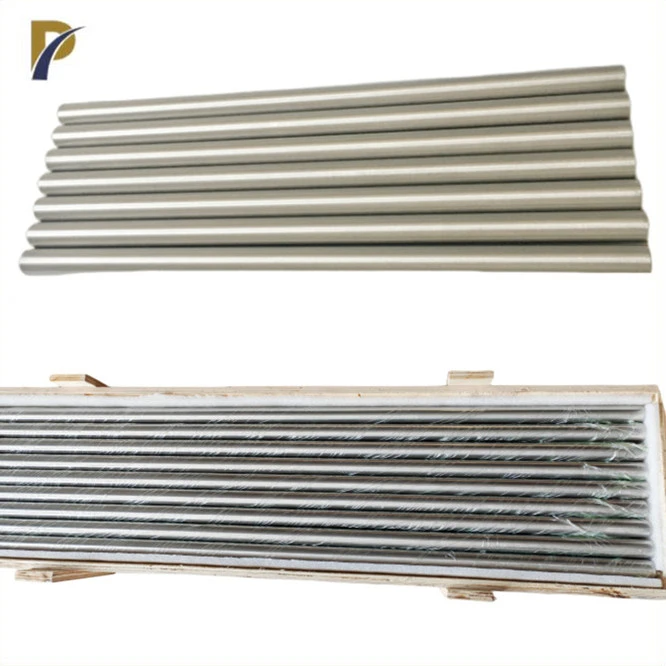

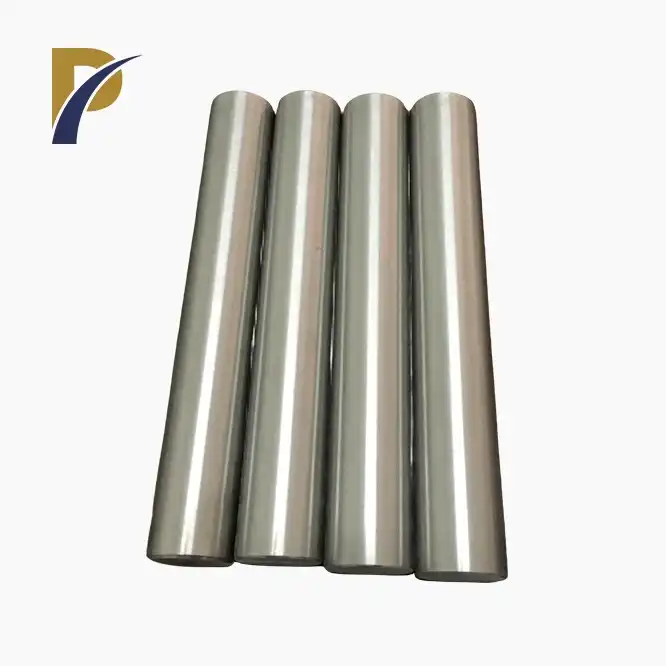

Zirconium Grade 702 Rod

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Grade 702 Rod – High-Performance Solution by Shaanxi Peakrise Metal Co., Ltd.

Zirconium Grade 702 Rods are widely recognized for their outstanding resistance to corrosion, particularly in harsh environments. With high ductility and superior performance in various industrial applications, this non-reactive metal is the material of choice in industries ranging from chemical processing to aerospace. As a leading supplier, Shaanxi Peakrise Metal Co., Ltd. specializes in providing high-quality Zirconium Grade 702 Rods, offering the strength, durability, and reliability required for demanding applications.

Our rods are manufactured to meet stringent industry standards, ensuring optimal performance. Whether for high-temperature environments or extreme corrosion resistance, our Zirconium Grade 702 Rods are the perfect fit for your industrial needs. With years of expertise in non-ferrous metals, Shaanxi Peakrise Metal Co., Ltd. is your trusted partner in zirconium production.

Product Specifications

| Property | Value |

|---|---|

| Standard | ASTM B550 |

| Diameter Range | 3 mm – 150 mm |

| Length | 500 mm – 6000 mm |

| Density | 6.51 g/cm³ |

| Melting Point | 1855°C |

| Tensile Strength | 379 MPa (min) |

| Yield Strength | 207 MPa (min) |

| Elongation | 20% (min) |

| Hardness | 115 – 160 HB |

Physical and Chemical Properties

Zirconium Grade 702 is composed primarily of zirconium with trace amounts of oxygen, iron, and nitrogen, making it resistant to corrosion and wear. The metal's physical and chemical properties are essential for applications where high strength, ductility, and resistance to aggressive media are critical.

- Density: 6.51 g/cm³

- Melting Point: 1855°C

- Corrosion Resistance: Exceptional in acidic and alkaline environments

- Thermal Conductivity: 22 W/m·K

- Coefficient of Thermal Expansion: 5.7 x 10⁻⁶/°C

|

|

|

|

Product Features

- Outstanding Corrosion Resistance: Zirconium Grade 702 exhibits exceptional resistance to corrosive media, particularly in acidic and high-temperature environments.

- High Ductility: Its high ductility allows for easier fabrication and processing, making it ideal for complex industrial applications.

- Excellent Strength-to-Weight Ratio: The material offers high tensile strength without being excessively heavy, making it efficient for aerospace and automotive industries.

- Non-Reactive: The metal is biocompatible and non-toxic, which expands its use into medical applications.

- Durability: Zirconium Grade 702 has a long service life due to its excellent wear and corrosion resistance, even in extreme conditions.

Applications of Zirconium Grade 702 Rod

-

Chemical Processing: Widely used in the manufacturing of heat exchangers, reactors, and piping systems in industries that handle corrosive chemicals. Zirconium's resistance to acid and alkali ensures safe and efficient operations.

-

Aerospace: Used in high-performance parts due to its strength-to-weight ratio and its ability to withstand high temperatures. This metal is critical for components exposed to extreme conditions.

-

Nuclear Energy: Zirconium Grade 702 plays a crucial role in the nuclear industry due to its low neutron absorption properties. It is commonly used in reactor cores and fuel cladding.

-

Medical Equipment: Due to its non-reactive and biocompatible nature, Zirconium Grade 702 is employed in the manufacturing of medical implants and surgical tools, particularly where corrosion resistance is essential.

-

Marine Environments: Due to its excellent corrosion resistance in saline environments, it is used in the construction of ship components and offshore structures.

Manufacturing Process & Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we follow a strict production process to ensure the highest quality Zirconium Grade 702 Rods:

- Material Selection: High-purity zirconium raw materials are sourced from certified suppliers.

- Melting Process: The metal is melted using vacuum arc remelting (VAR) and plasma electron beam melting to achieve a uniform composition.

- Forming: The melted zirconium is processed into rods using advanced rolling mills and drawing machines to ensure consistent dimensions.

- Heat Treatment: The rods undergo vacuum annealing to enhance their ductility and mechanical properties.

- Inspection: Each batch undergoes rigorous quality checks including tensile tests, hardness measurements, and surface inspections.

Why Choose Shaanxi Peakrise Metal Co., Ltd.?

- Extensive Industry Experience: With over a decade of experience in non-ferrous metal production, we have the expertise to deliver high-quality zirconium products.

- Global Presence: Our products are exported to over 20 countries, including the United States, Germany, and South Korea, with long-term partnerships established worldwide.

- State-of-the-Art Equipment: Our factory is equipped with advanced machinery, ensuring precision and high production efficiency.

- Comprehensive Quality Control: We adhere to international standards for quality control, ensuring our products meet or exceed customer expectations.

- Custom Solutions: We offer tailor-made zirconium rod solutions to meet the specific needs of each client.

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer flexible OEM/ODM services for clients who require custom specifications or products. Whether you need a specific diameter, length, or surface finish, we can accommodate your needs. Our skilled engineers work closely with customers to ensure each product is manufactured to precise requirements.

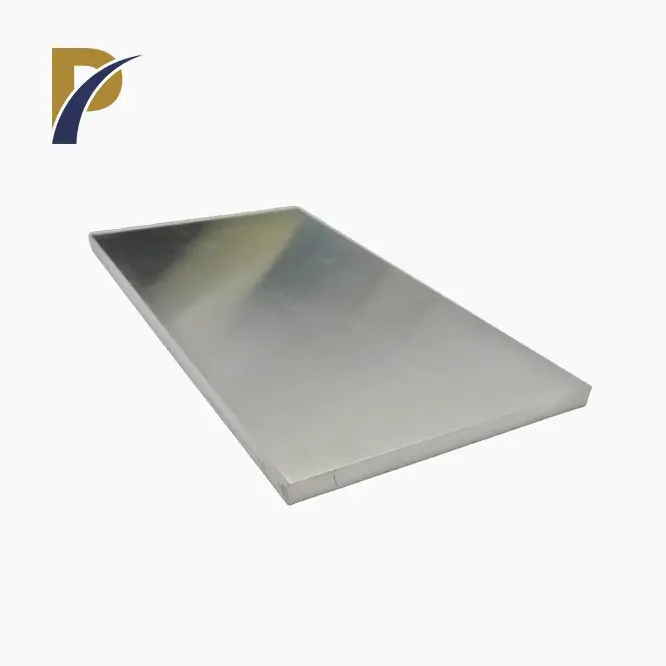

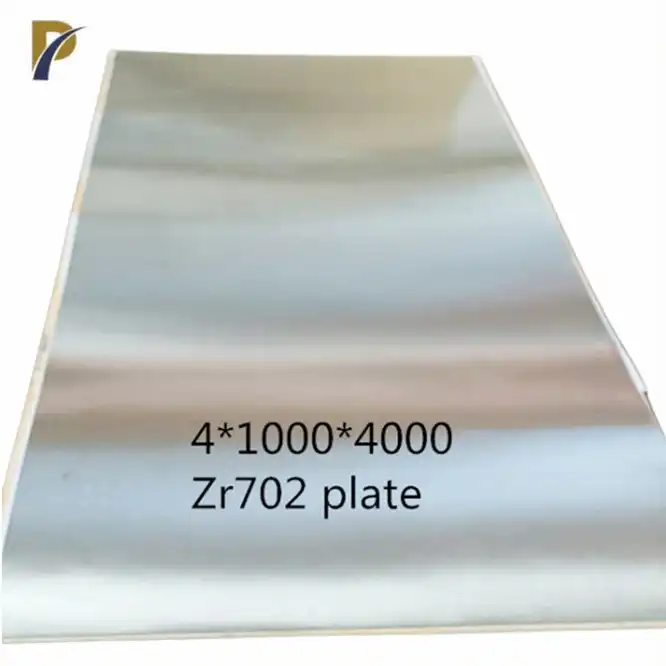

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

FAQ

-

What is the delivery time for Zirconium Grade 702 Rods?

Our standard delivery time is 4-6 weeks. Expedited options are available upon request. -

Can you provide custom sizes?

Yes, we offer customization to meet your exact specifications, including diameters and lengths. -

What payment methods do you accept?

We accept T/T, L/C, and other international payment methods. -

How do you ensure product quality?

All our products undergo strict quality control measures, including chemical composition analysis and mechanical property testing. -

Do you ship internationally?

Yes, we ship our products globally, with extensive experience in handling international logistics.

Packaging

- Wooden Box Packaging: Ideal for long-distance transportation, providing maximum protection against impact and environmental factors.

- Carton Packaging: Suitable for smaller orders, offering cost-effective yet sturdy protection.

- Foam Fill Packaging: Protects against vibration and shock during transit, ensuring product integrity.

- Waterproof Packaging: Ensures the product remains unaffected by moisture during shipping.

- Custom Packaging: Tailored to meet specific customer requirements, ensuring secure and safe delivery.

Logistics

- Sea Freight: Cost-effective for large shipments with a longer delivery time.

- Air Freight: Faster option for urgent orders, with worldwide delivery.

- Land Freight: Available for local and cross-border shipments.

- Multimodal Transport: Combining sea, air, and land for optimized delivery solutions.

- Courier Services: Ideal for smaller, time-sensitive orders.

Contact Us – Partner with Shaanxi Peakrise Metal Co., Ltd.

Ready to take your project to the next level with high-quality Zirconium Grade 702 Rods? Contact us today at info@peakrisemetal.com to discuss your requirements. Our team is ready to provide personalized support and offer the best solutions for your specific needs. Let's work together to build a lasting partnership!

YOU MAY LIKE

-

VIEW MORE35ml zirconium crucible

VIEW MORE35ml zirconium crucible -

VIEW MOREsic rod heater element

VIEW MOREsic rod heater element -

VIEW MOREZirconium Industrial Rods

VIEW MOREZirconium Industrial Rods -

VIEW MOREZr702 Zirconium Rod 23mm 24mm 25mm 26mm 27mm

VIEW MOREZr702 Zirconium Rod 23mm 24mm 25mm 26mm 27mm -

VIEW MOREZirconium Sheet for Chemical Use

VIEW MOREZirconium Sheet for Chemical Use -

VIEW MORE0.5mm,0.3mm,0.25mm Zr702 Zirconium Wire In Coil Zirconium Wire

VIEW MORE0.5mm,0.3mm,0.25mm Zr702 Zirconium Wire In Coil Zirconium Wire -

VIEW MOREUltra-Thin Zirconium Metal Foil

VIEW MOREUltra-Thin Zirconium Metal Foil -

VIEW MOREZr 702 cylindrical zirconium crucible

VIEW MOREZr 702 cylindrical zirconium crucible