Zirconium Alloy Thin Foil

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Alloy Thin Foil Product Introduction Page

Product Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of Zirconium Alloy Thin Foil. With extensive experience in the production of non-ferrous metals, we specialize in providing high-quality zirconium alloys that meet the rigorous standards of various industries. Our Zirconium Alloy Thin Foil is engineered to deliver outstanding performance and reliability, making it an essential choice for a wide range of applications.

Zirconium alloys are known for their exceptional corrosion resistance, high melting point, and excellent mechanical properties. These attributes make them ideal for use in harsh environments, such as nuclear reactors, chemical processing, and aerospace applications. At Shaanxi Peakrise Metal, we understand the critical role that quality plays in your projects, which is why we prioritize the use of advanced manufacturing techniques and strict quality control measures to ensure that our products exceed your expectations.

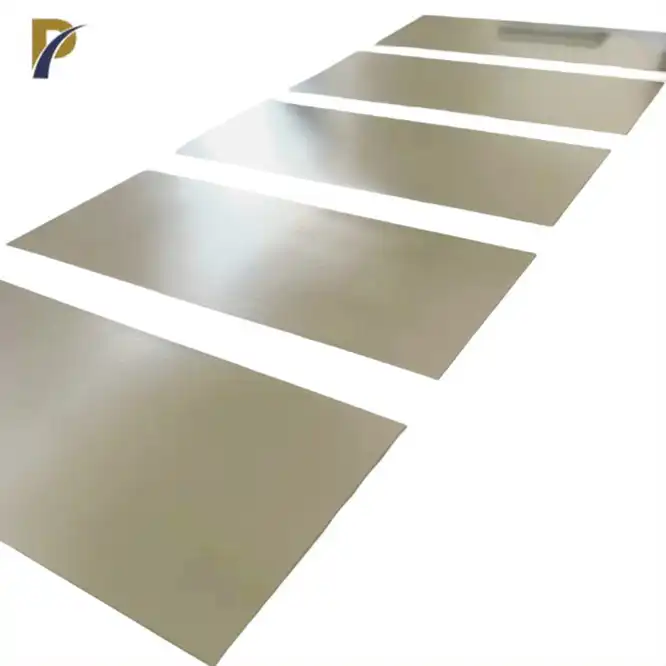

As a reputable supplier in the global market, we are committed to delivering not just products, but also solutions that meet the unique needs of our customers. Our Zirconium Alloy Thin Foil is available in various thicknesses and dimensions, allowing for customization to suit specific requirements. With our expertise and dedication to excellence, we are here to support your business in achieving its goals.

Product Specifications

| Specification | Value |

|---|---|

| Alloy Type | Zirconium Alloy |

| Thickness | 0.01 mm - 0.5 mm |

| Width | 100 mm - 500 mm |

| Length | Customizable |

| Density | 6.5 g/cm³ |

| Melting Point | 1855 °C |

| Tensile Strength | 200 MPa |

| Elongation | 25% |

| Designation | Description | Condition | Size(mm) | ||

| Thickness | Width | Length | |||

|

Zr01 Zr-1 Zr702

|

Foil |

Cold rolling R) Recrystallized (Y) Eliminate stress state (m)

|

0.05~0.13 | 50~200 | ≥500 |

| Strip | >0.13~0.5 | 50~300 | ≥300 | ||

| Plate | >0.3~10.0 | 50~600 | ≥500 | ||

|

|

|

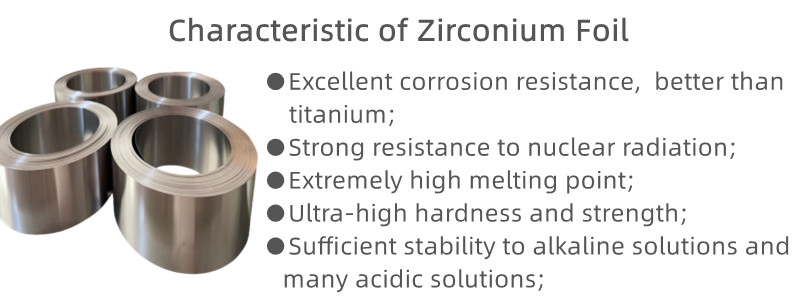

Physical and Chemical Properties

Zirconium alloys possess unique physical and chemical properties that enhance their usability across various industries:

- Corrosion Resistance: Excellent resistance to oxidation and corrosion, particularly in acidic environments, making them suitable for chemical processing and nuclear applications.

- High Melting Point: With a melting point of approximately 1855 °C, zirconium alloys maintain their structural integrity at elevated temperatures.

- Low Thermal Neutron Absorption: This property is critical for nuclear applications, allowing for effective performance in reactors.

- Good Workability: Zirconium alloys can be easily processed into thin foils, sheets, and other forms, allowing for versatile applications.

Surface Condition of Zirconium foil

| Surface: | The sheets are free from impurities, splits, fractures and indentations,having an impact on a common processing or application of the product. |

| Surface roughness: | Cold rolled. bright: Ra ≤ 0.80 μm Cold rolled. ground: Ra ≤ 1.20 μm Cold rolled. pickled (dull): Ra ≤ 1.60 μm |

Product Functions

The Zirconium Alloy Thin Foil offers a range of functionalities that make it indispensable in various applications:

- Corrosion Protection: The exceptional corrosion resistance of zirconium alloys ensures durability and longevity in challenging environments.

- Thermal Stability: Withstand high temperatures without losing strength or structure, making them suitable for high-performance applications.

- Neutron Absorption: Ideal for nuclear applications where low thermal neutron absorption is required, ensuring safety and efficiency.

- Ductility: The ability to be formed into thin foils without breaking enhances its application in intricate designs and components.

- Chemical Reactivity: High resistance to chemical reactions allows for safe use in chemical processing industries.

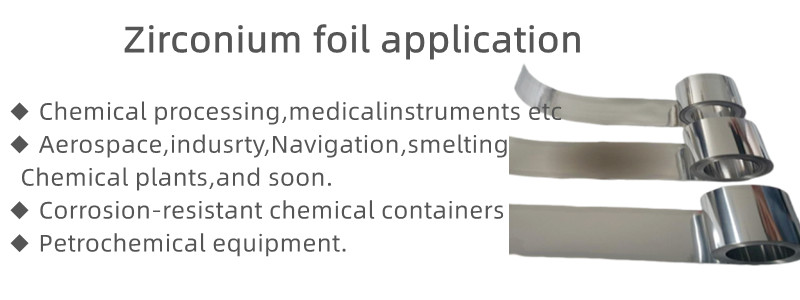

Product Applications

The Zirconium Alloy Thin Foil serves various industries and applications:

- Nuclear Energy: Used in fuel rod cladding due to its low neutron absorption and excellent corrosion resistance, ensuring efficient reactor operation.

- Chemical Processing: Employed in reactors and storage vessels, providing protection against corrosive chemicals and high temperatures.

- Aerospace: Utilized in components that require lightweight yet strong materials capable of withstanding extreme conditions.

- Medical Devices: Used in implants and surgical instruments due to biocompatibility and resistance to bodily fluids.

- Electronics: Applied in the manufacturing of capacitors and other electronic components where high-performance materials are crucial.

Manufacturing Process

Our Zirconium Alloy Thin Foil is produced through a meticulous manufacturing process that ensures high quality and consistency:

- Material Selection: High-grade zirconium alloy ingots are sourced to ensure optimal performance.

- Melting: The selected material is melted using a vacuum arc melting furnace to eliminate impurities and enhance material properties.

- Forming: The molten zirconium alloy is cast into billets, which are then processed into thin sheets through rolling and extrusion techniques.

- Annealing: The foils undergo a controlled annealing process to relieve internal stresses and improve ductility.

- Cutting and Finishing: The foils are cut to the required dimensions and undergo surface finishing to ensure a smooth finish.

- Quality Control: Each batch is rigorously tested for compliance with international standards, ensuring high performance and reliability.

Our Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. is a rich and experienced manufacturer specializing in non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Our product portfolio features over 100 kinds of products, including tungsten-copper alloys, molybdenum-copper alloys, and high-specific-gravity tungsten alloys.

Since 2010, we have focused on exporting high-quality non-ferrous metal products to international markets. Our comprehensive production enterprise integrates manufacturing, processing, material research and development, product testing, and stock inventory. This allows us to maintain high-quality standards while continually expanding into new fields to meet global demand.

Our advanced manufacturing facility is equipped with various production equipment, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, and CNC machines. This investment in technology enables us to produce superior quality products while optimizing efficiency.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We understand the importance of reliable logistics and packaging solutions. Therefore, we offer various options to ensure that your orders are delivered safely and promptly:

Packaging Options

- Wooden Crate Packaging: Provides robust protection during transit, ensuring that your products arrive intact.

- Carton Packaging: Lightweight and efficient for smaller items, suitable for cost-effective shipping.

- Foam Filling: Additional cushioning for delicate products, preventing damage during transport.

- Waterproof and Moisture-Proof Packaging: Essential for products sensitive to moisture, ensuring product integrity.

- Custom Packaging: Tailored solutions to meet specific client requirements, enhancing presentation and protection.

- International Standard Packaging: Ensures compliance with global shipping regulations, facilitating smooth customs clearance.

Logistics Solutions

- Sea Freight: Cost-effective for bulk orders, ensuring reliable delivery across international waters.

- Air Freight: Fast shipping option for urgent orders, ideal for time-sensitive applications.

- Land Transportation: Efficient for regional deliveries, ensuring prompt service within a specific area.

- Multimodal Transport: Combines various transportation methods for optimized logistics, reducing transit time and costs.

- Express Services: Fast and reliable delivery for urgent orders, ensuring customer satisfaction.

Why Choose Us?

Choosing Shaanxi Peakrise Metal Co., Ltd. as your supplier comes with numerous advantages:

- Expertise and Experience: With years of experience in non-ferrous metal production, we understand the intricacies of the industry and are equipped to meet diverse client needs.

- High-Quality Products: Our commitment to quality ensures that every product meets stringent standards, providing you with reliability and performance.

- Comprehensive Services: From OEM/ODM services to custom packaging, we offer a full range of services to support your business requirements.

- Global Reach: Our products are exported to numerous countries, establishing long-term partnerships and trust with clients worldwide.

- Continuous Innovation: We invest in research and development to stay ahead of industry trends and provide cutting-edge solutions to our customers.

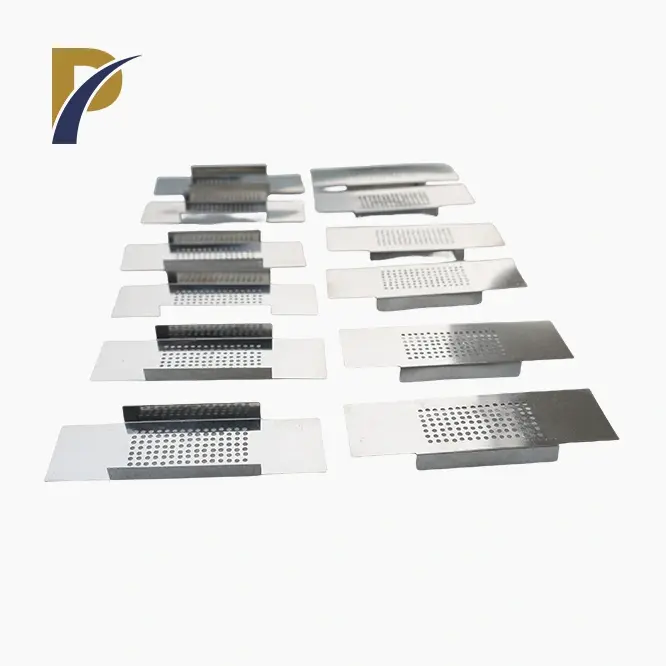

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we support custom processing services tailored to your specific needs. Whether you require unique dimensions, specialized properties, or custom packaging, our team is ready to assist you in creating the perfect solution for your applications.

|

|

|

|

|

|

|

|

|

Frequently Asked Questions (FAQs)

-

What thickness options are available for Zirconium Alloy Thin Foil?

- We offer a range of thicknesses from 0.01 mm to 0.5 mm, with customization available based on your requirements.

-

What industries utilize Zirconium Alloy Thin Foil?

- Our foils are used in nuclear energy, chemical processing, aerospace, medical devices, and electronics.

-

Do you provide samples for testing?

- Yes, we can provide samples upon request to ensure our products meet your specifications before placing a bulk order.

-

What is the lead time for production?

- Lead times vary depending on order size and complexity. Please contact us for a specific timeline.

-

Can you assist with custom packaging?

- Absolutely! We offer custom packaging solutions to meet your specific shipping and presentation needs.

Contact Us

Are you ready to enhance your projects with our high-quality Zirconium Alloy Thin Foil? At Shaanxi Peakrise Metal Co., Ltd., we are committed to providing you with the best products and services to meet your needs. Don't hesitate to reach out to us for inquiries or to place an order.

For more information, please contact us at info@peakrisemetal.com. We look forward to partnering with you for your success!

YOU MAY LIKE

-

VIEW MOREHigh-Strength Zirconium Wire

VIEW MOREHigh-Strength Zirconium Wire -

VIEW MOREZirconium Metal Foil for Industry

VIEW MOREZirconium Metal Foil for Industry -

VIEW MORECold-Rolled Zirconium Alloy Sheet

VIEW MORECold-Rolled Zirconium Alloy Sheet -

VIEW MOREASTM B550 Zirconium Alloy Wire

VIEW MOREASTM B550 Zirconium Alloy Wire -

VIEW MOREAerospace Zirconium Rods

VIEW MOREAerospace Zirconium Rods -

VIEW MORELS shape (double helix) silicon carbide heating element

VIEW MORELS shape (double helix) silicon carbide heating element -

VIEW MOREU Shape MoSi2 Heating Elements For Muffle Furnace

VIEW MOREU Shape MoSi2 Heating Elements For Muffle Furnace -

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator